Corrugated paper pulp waste extruding packaging equipment

A technology for corrugated paper and pulp, applied in the field of waste compression, can solve the problems of ineffective liquid discharge, poor compression effect, increased transportation cost, etc., and achieves the effect of convenient cleaning, simple setting and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments. It should be understood that the examples are only for explaining the present invention and not for limiting it.

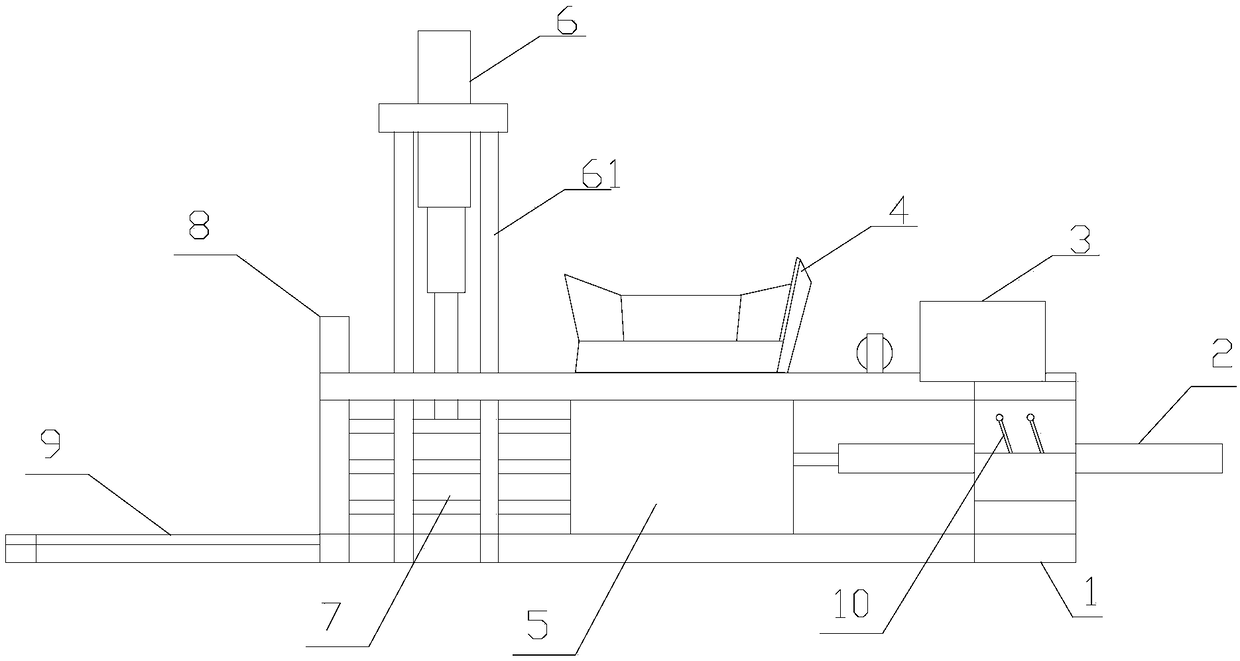

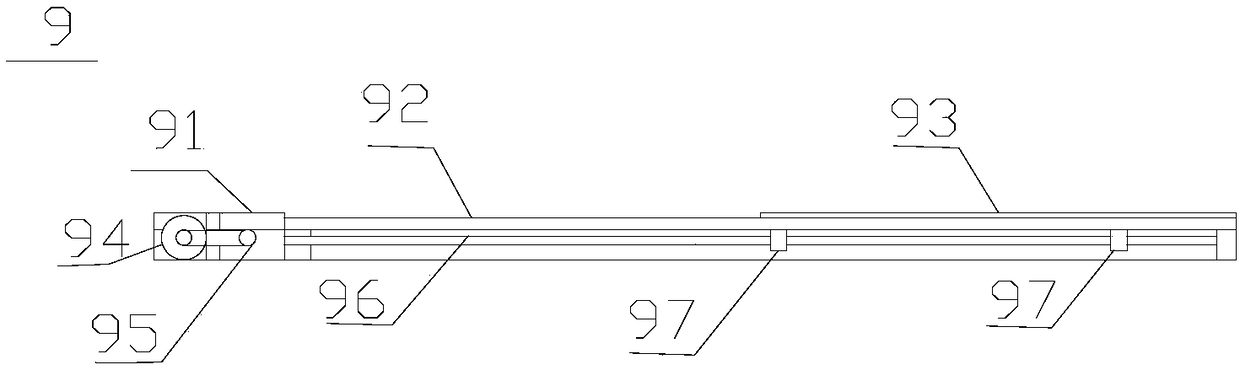

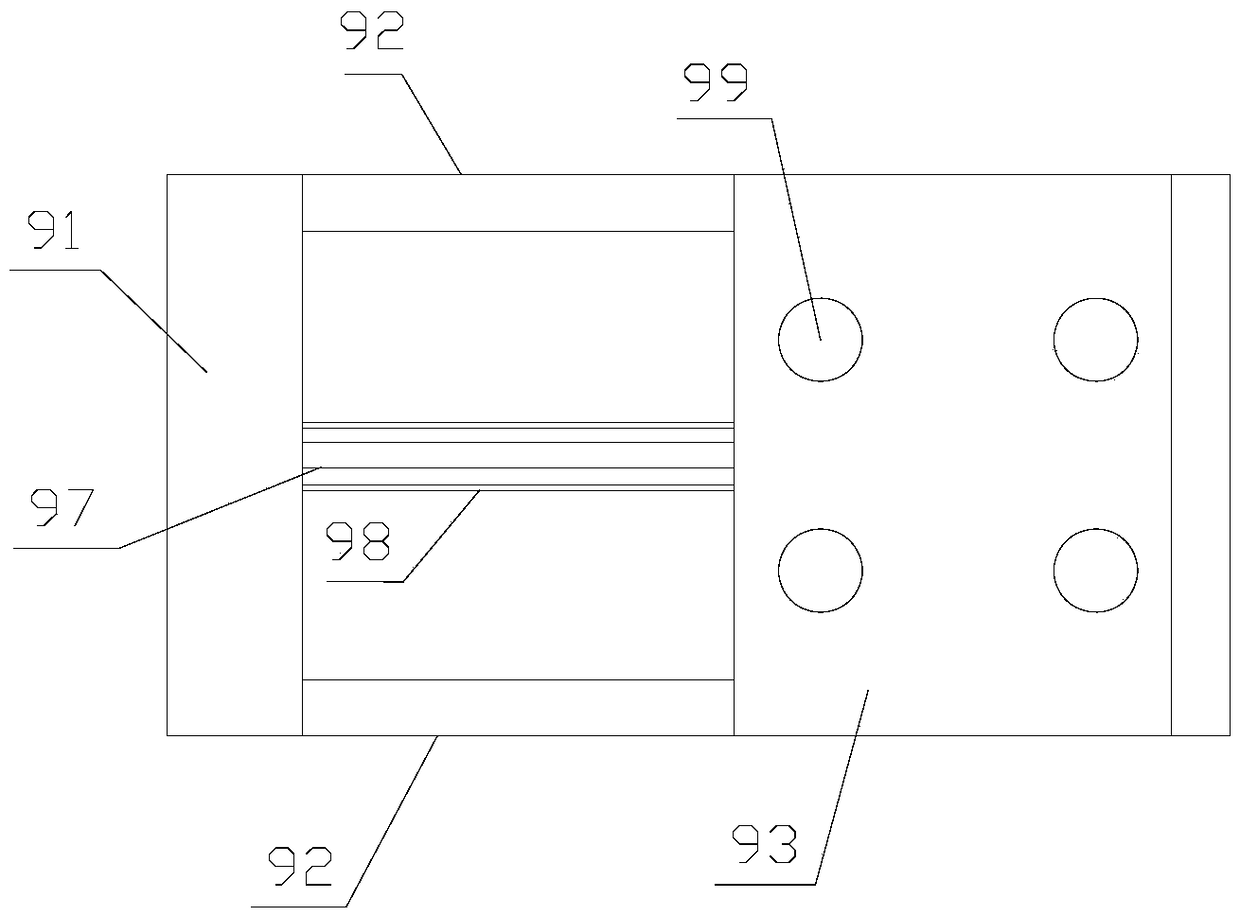

[0030] A corrugated paper pulp waste extrusion packaging equipment, including a frame structure 1, the frame structure 1 is a rectangular frame steel structure, a first compression cylinder 2 is arranged on the square frame body at the left end of the frame structure 1, and the first compression cylinder 2. A power unit 3 is provided on the upper frame structure. The power unit 3 includes a hydraulic press, a motor, etc., which are commonly used to provide power for the first compression cylinder 2 and push the piston at one end of the first compression cylinder to move. A semi-open funnel-shaped feed inlet 4 is provided above the frame structure 1, and the feed inlet 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com