Multifunctional dyeing machine

A cloth dyeing machine and multi-functional technology, applied in the field of textile printing and dyeing, can solve the problems of affecting the quality of cloth, easily soiling clothes, low efficiency, etc., and achieve the effect of saving dyeing time, speeding up drying speed and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

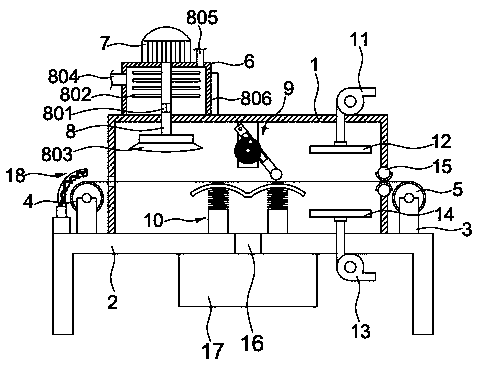

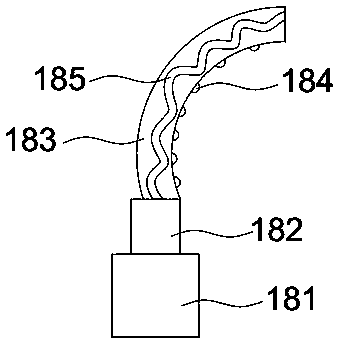

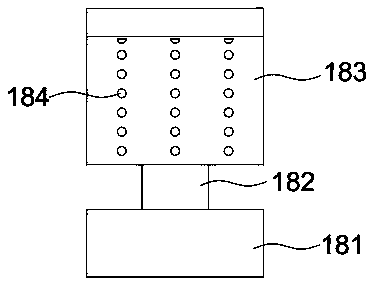

[0026] Such as Figure 1-5As shown, the solution adopted by the present invention to solve the above-mentioned technical problems is: a multi-functional cloth dyeing machine, including a housing 1 positioned on the upper surface of the frame 2, the bottom of the housing 1 is provided with a sewage outlet 16, and the sewage outlet 16 is connected to the bottom of the machine. The sewage collection box 17 below the frame 2 is connected, the top of the housing 1 is provided with a dye tank 6, the left and right sides of the housing 1 are provided with support bases 3, and the support bases 3 are respectively equipped with first cloth rolls that are movably connected by rollers. 4 and the second cloth rolling roller 5, the inner walls on both sides of the housing 1 are provided with slots for cloth to pass through, and the first cloth rolling roller 4 is provided with a preheating mechanism 18 on one side, and the preheating mechanism 18 includes an air pump 181, The air outlet pi...

Embodiment 2

[0028] Such as figure 1 As shown, the optimization scheme of this embodiment on the basis of Embodiment 1 is: a rotating motor 7 is arranged above the dye tank 6, and the output end of the rotating motor 7 passes through the dye tank 6 to be connected to a discharge pipe 8, and the discharge pipe 8 Stirring rods 802 are evenly distributed on the top, driven by the rotating motor 7 to drive the stirring rods 802 to rotate, the dye and clear water can be stirred evenly, and then the dyeing of the cloth can be dyed more evenly when the dye is dyed, and the color depth of the dyed cloth can be avoided. The first situation improves the quality of the dyed cloth. The discharge pipe 8 below the stirring rod 802 is provided with a through hole 801. The discharge pipe 8 is movably connected with the housing 1, and the discharge pipe 8 in the housing 1 The end is connected with a nozzle 803, and the uniformly stirred dye enters the inside of the discharge pipe 8 through the through hole...

Embodiment 3

[0030] Such as figure 1 , 6 , 7, and 8, the optimization scheme of this embodiment on the basis of Embodiment 1 is: the top of the housing 1 is provided with a swing device 9, the swing device 9 includes a support plate 901, and the support plate 901 is movable through a fixed rod 905 A swing rod 904 is connected, and a bar-shaped hole 906 is opened on the swing rod 904. A cylinder 908 is arranged at the bottom of the swing rod 904. A disc 902 is movably connected between the swing rod 904 and the support plate 901 through an axis column 903. 902 is driven and rotated by the motor 909 on the back of the support plate 901, the disc is provided with a fixed block 907, and the fixed block 907 is connected with the strip hole 906, and the inner bottom of the housing 1 is provided with an elastic seat 10, which includes a base 101 , the base 101 is provided with a spring 102, the spring 102 is provided with an arc-shaped block 103, and the arc-shaped block 103 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com