System for preventing spontaneous combustion by pouring loess consolidation agent into goaf and grouting method thereof

A consolidating agent, goaf technology, applied in soil protection, infrastructure engineering, construction, etc., to achieve the effect of good impermeability, low viscosity and strong injectability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

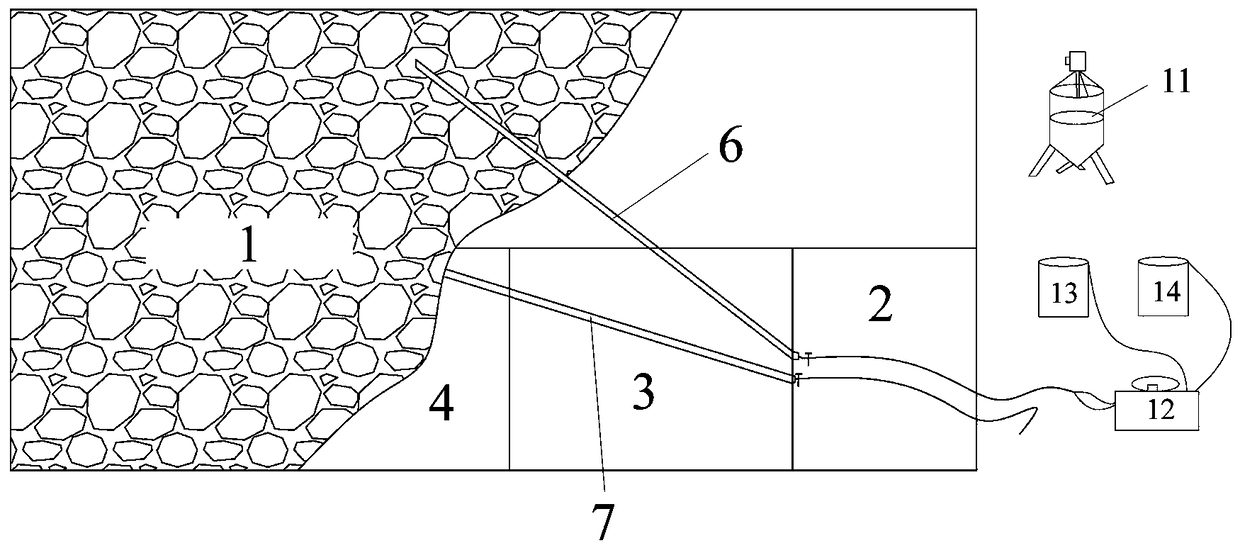

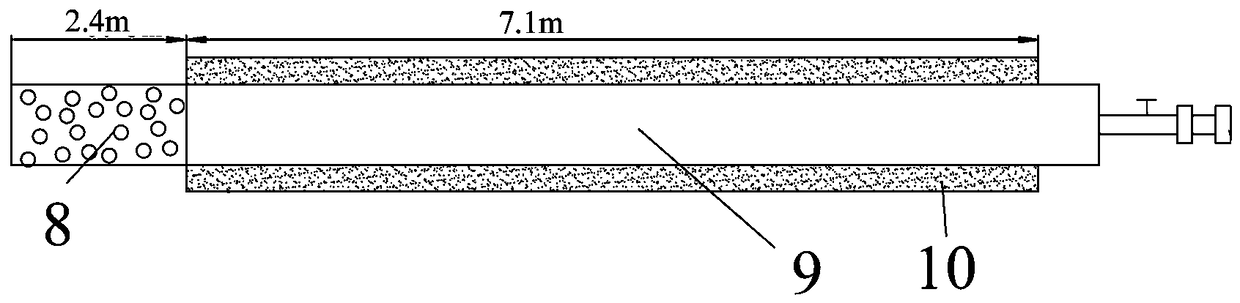

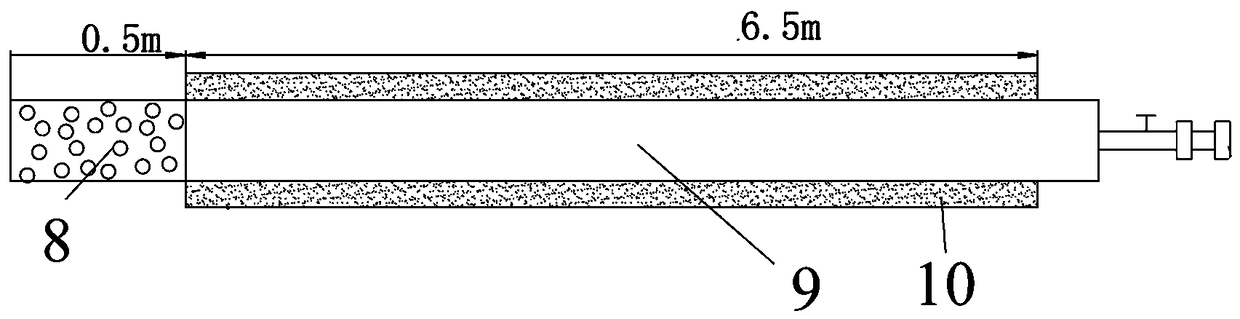

[0027] A goaf pouring loess consolidation agent to prevent spontaneous combustion system, such as Figure 1 to Figure 4 As shown, it includes multiple sets of boreholes, each set of boreholes runs through the coal pillar, each set of boreholes includes a high-level grouting hole 6 and a low-level grouting hole 7, and the angle between the high-level grouting hole 6 and the horizontal plane is greater than The angle between the low-level grouting hole 7 and the horizontal plane, the high-level grouting hole 6 and the low-level grouting hole 7 are all equipped with a drilling casing 9, and the drilling casing 9 extends out of the coal pillar and into the goaf The ends in the zone 1 are flower tubes 8, the distance between each group of boreholes is 9-10 meters, and cement slurry 10 is poured between the borehole casing 9 and the boreholes, and the borehole casing 9 is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com