Large-span pipe truss hoisting method

A hoisting method and pipe truss technology, which is applied in the direction of construction, building structure, and building material processing, can solve problems such as difficult installation of large-span space structures, reduce the amount of assembly work, improve project quality, and save costs for mechanical measures and duration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

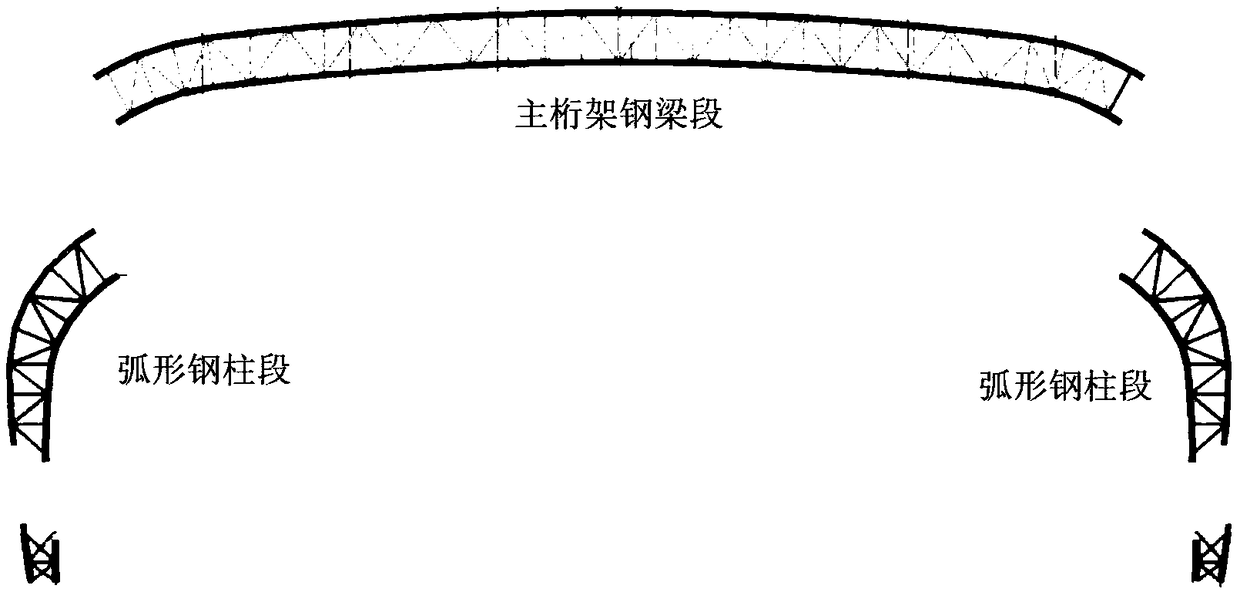

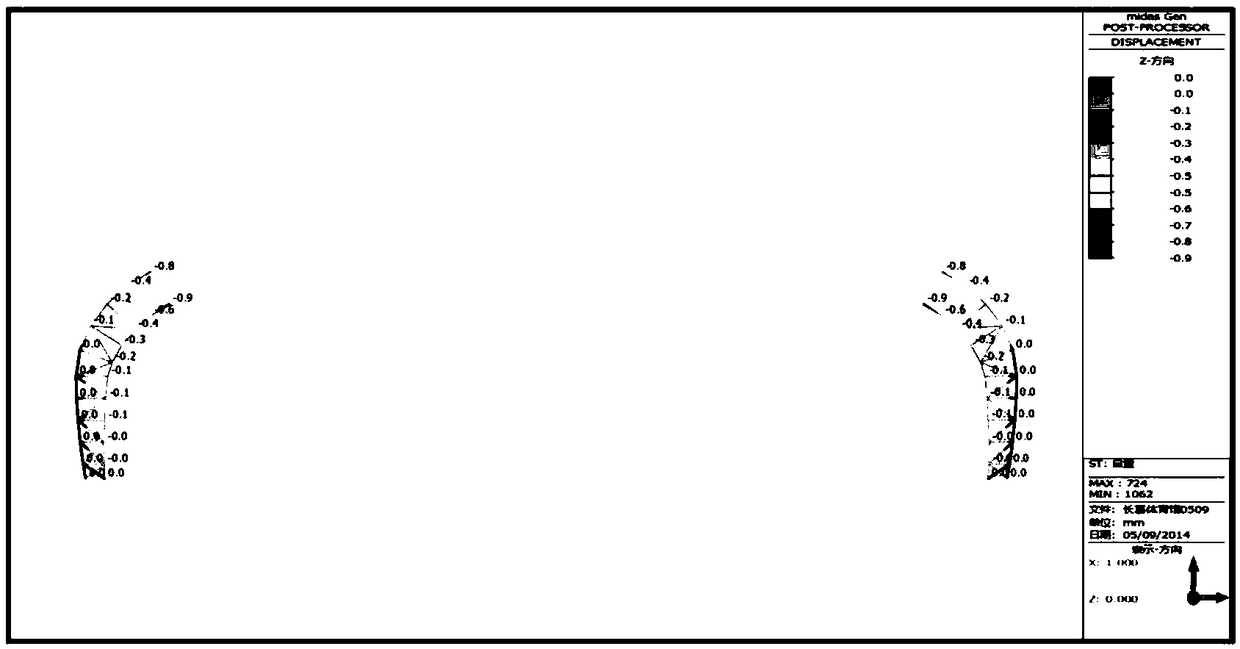

[0051] refer to Figure 1-28 , a method for hoisting a large-span pipe truss, comprising the following steps:

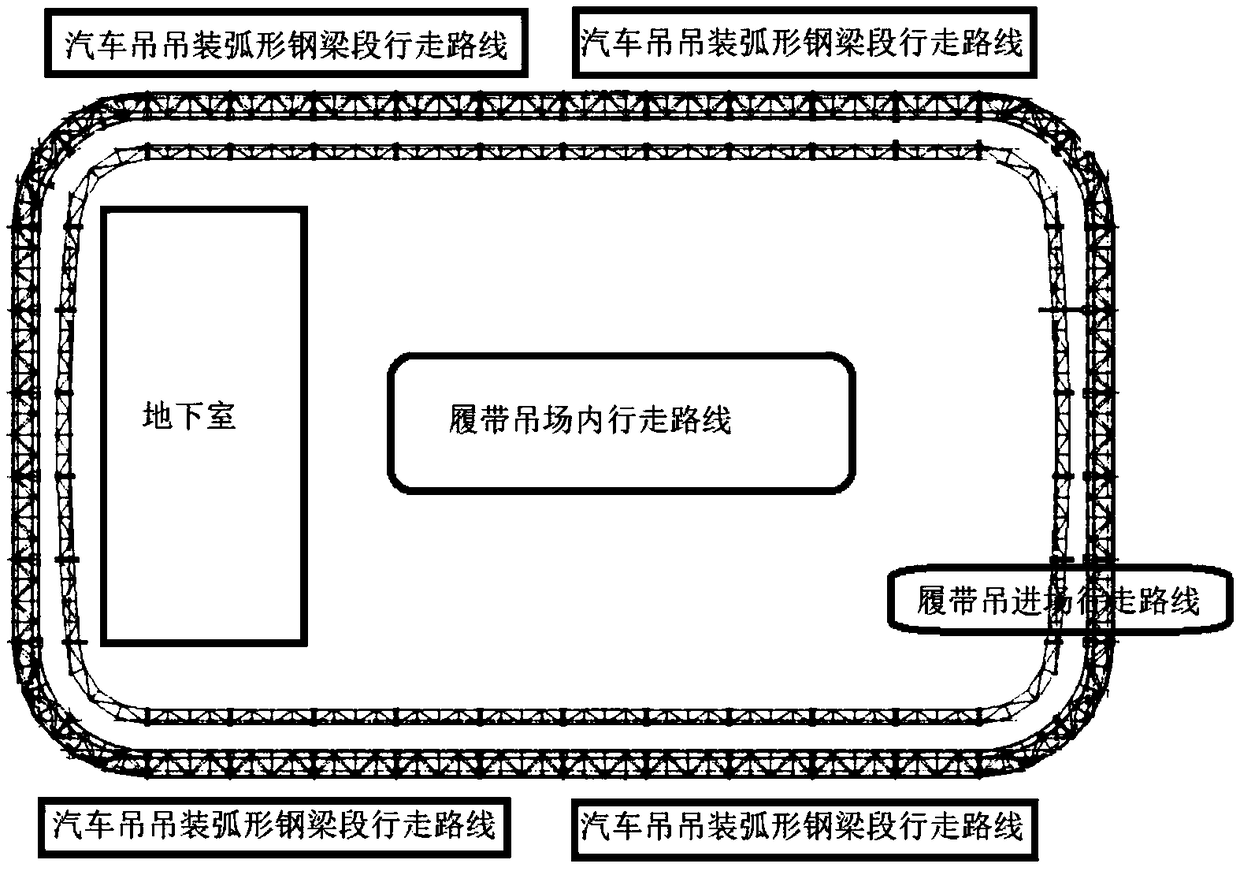

[0052] Step 1, measurement review: a1. First use the total station to locate the position of the column foot of the steel truss column in the arc section, then use theodolite and steel tape to check the distance between the column foot and the linearity of the two column feet of the same plane truss, and the plane truss itself When hoisting in three sections, the straight line distribution between each section prevents additional stress between the trusses of each section; figure 2 According to the working conditions of the construction site, arrange the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com