Biomass and domestic waste incineration power generation integrated plant layout structure

A technology of domestic waste incineration and plant layout, applied in industrial buildings and other directions, can solve the problems of biomass construction and operation, insufficient straw resources, operation and income impact, etc., to increase the overall return on investment, social significance, anti- The effect of strong risk ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

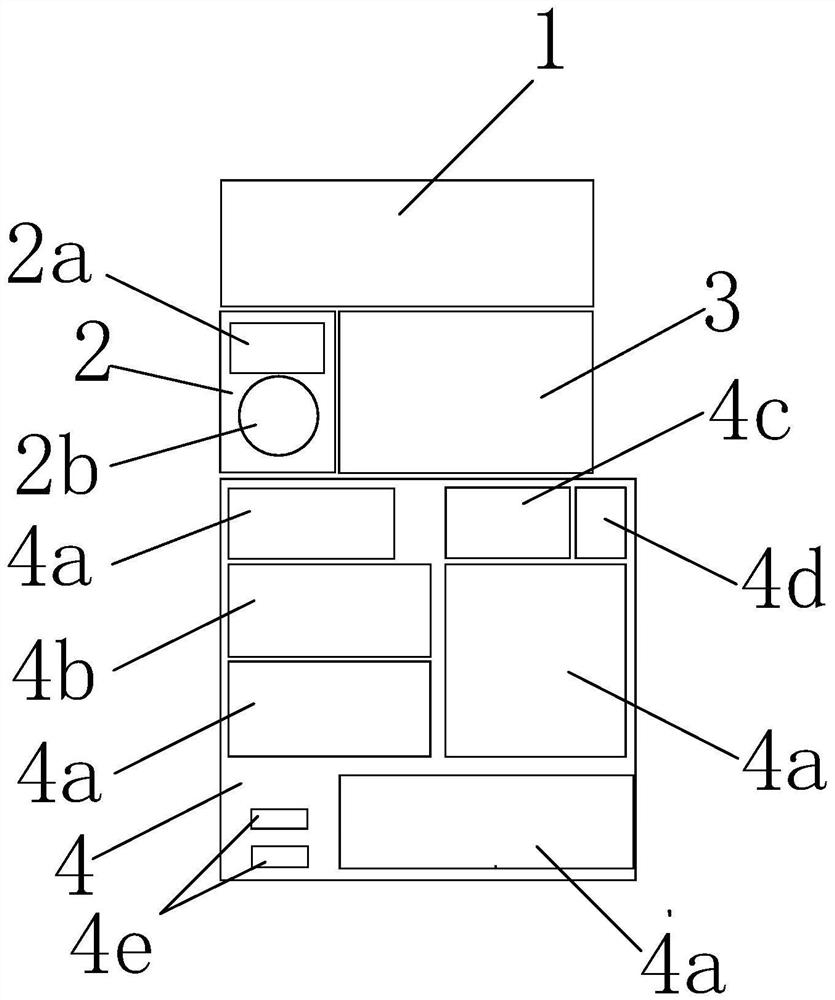

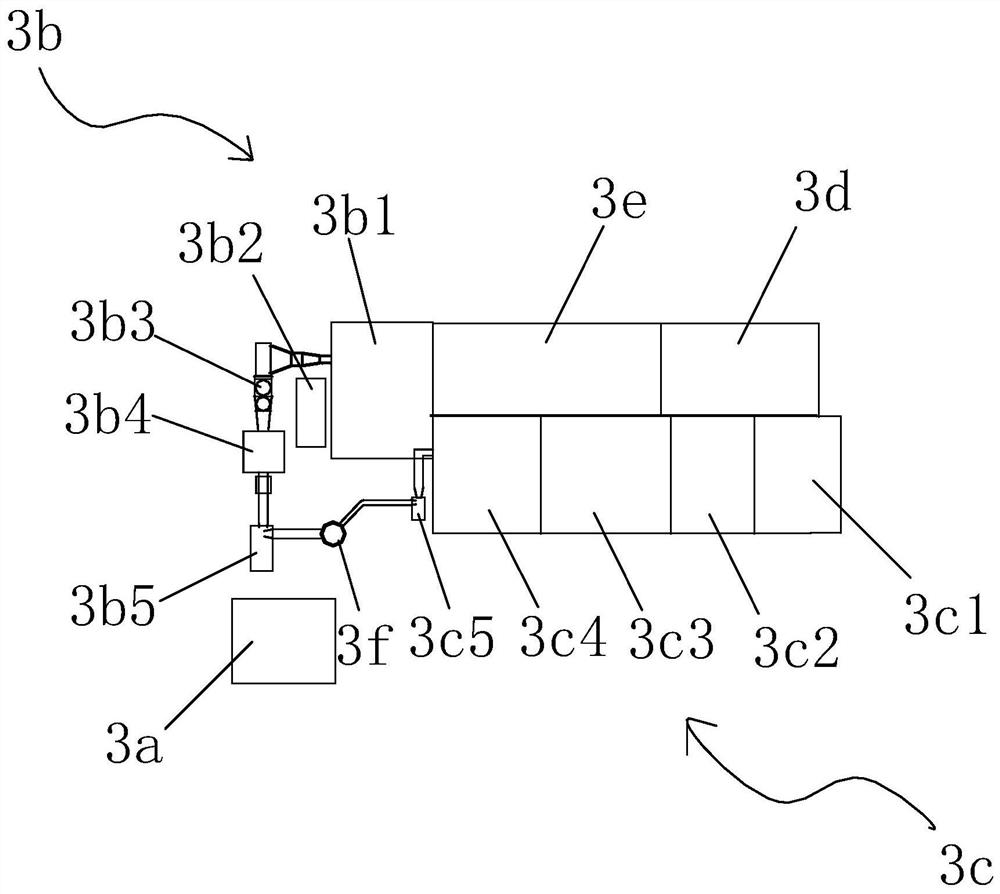

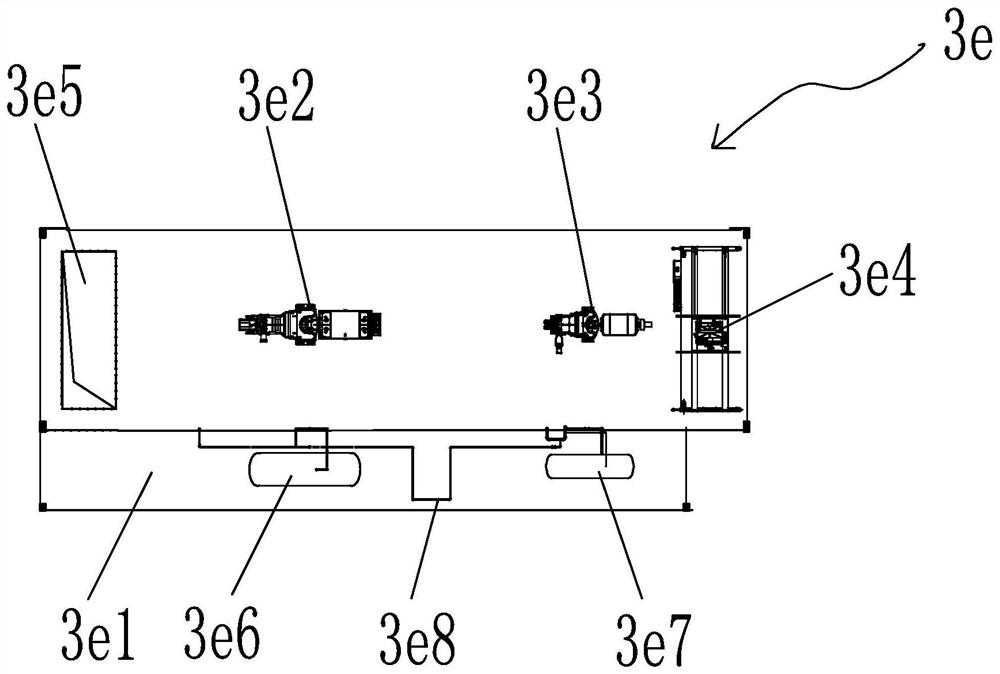

[0015] Such as figure 1 The layout structure of the integrated biomass and domestic waste incineration power generation plant shown includes the front area 1 for living and office work, the circulating water facility area 2 close to the front area of the plant, the main plant area 3, and the circulating water facility area 2 and the fuel facility area 4 of the main plant area 3, the circulating water facility area 2 includes a comprehensive water pump room 2a and a natural ventilation cooling tower 2b, and the main plant area 3 includes an air compressor room and a warehouse 3a, a biomass power plant area 3b and waste incineration power plant area 3c, the biomass power plant area 3b includes the entrance hall and control room 3d, steam turbine room 3e, biomass boiler room 3b1, slag room 3b2, desulfurization device 3b3, dust collector 3b4, bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com