Self-cleaning chimney

A self-cleaning, chimney technology, applied in the direction of combustion product treatment, combustion method, solid residue removal, etc., can solve the problem of lack of cleaning mechanism in the chimney, achieve the effect of reducing maintenance frequency, outstanding effect, and increasing the circulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

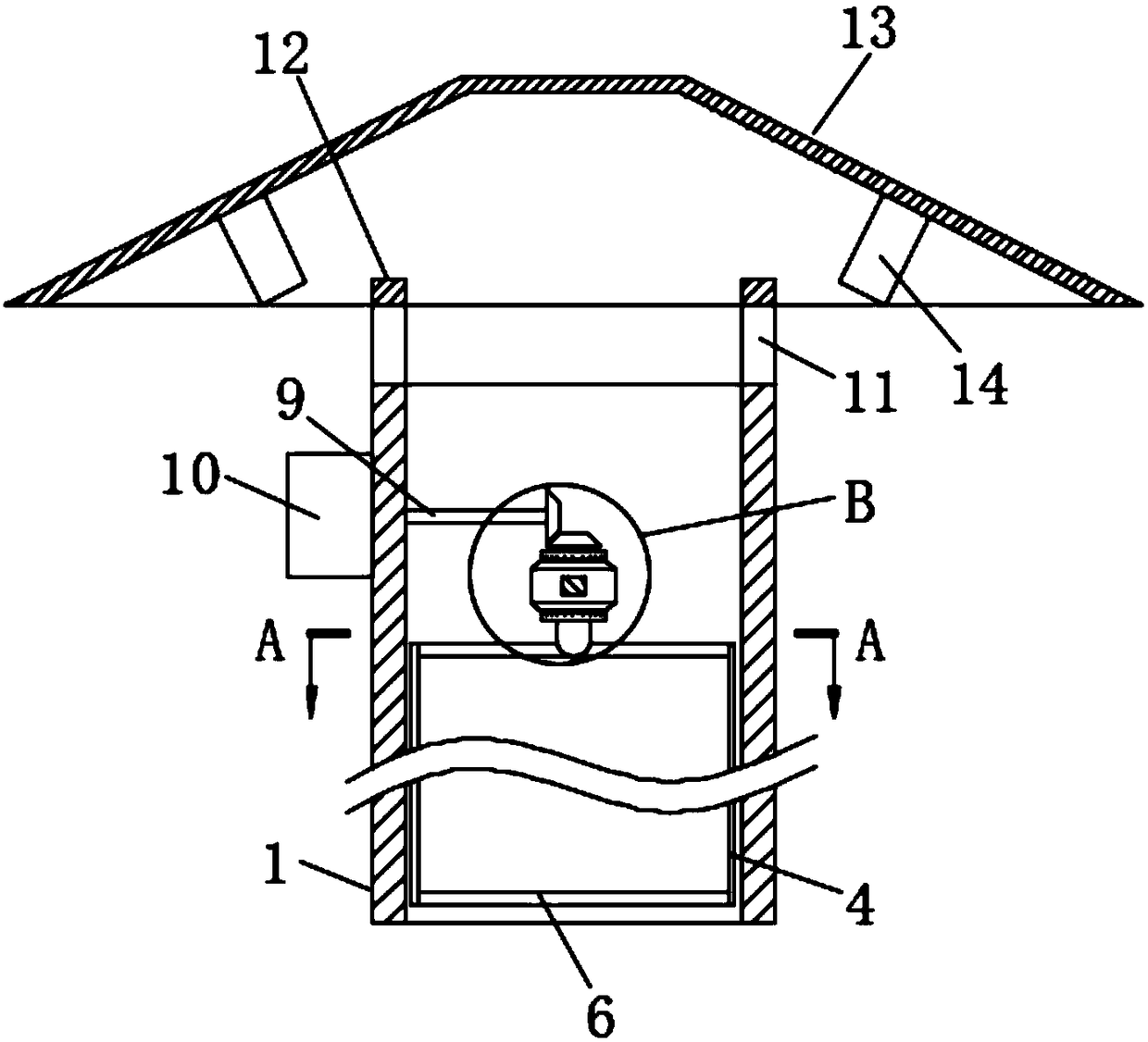

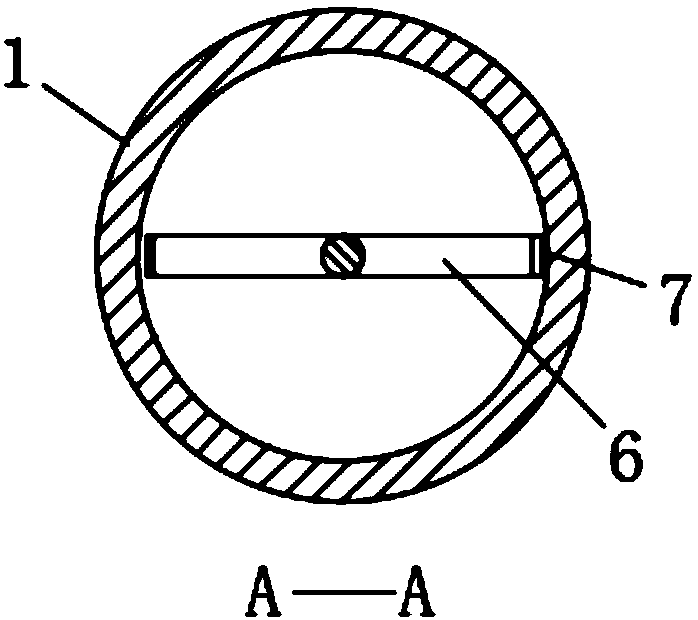

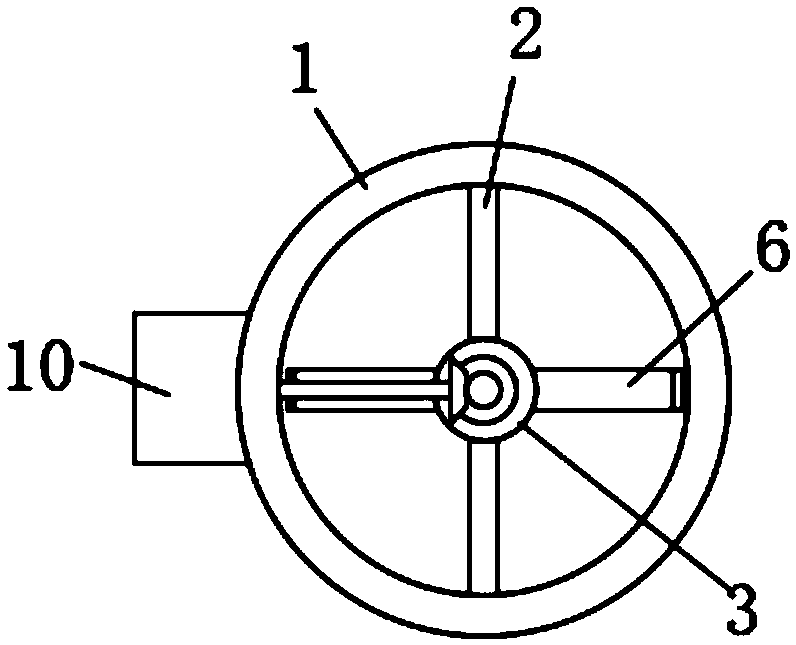

[0030] refer to Figure 1-5 , a self-cleaning chimney, including a chimney 1, two mounting rods 2 are symmetrically fixedly connected to the inner wall of the chimney 1, and a fixing seat 3 is installed between the two mounting rods 2, and the top and bottom ends of the fixing seat 3 are both A bevel of 45 degrees is set upside down, and a bevel is set on the fixing seat 3 so that the smoke can flow upward more smoothly without being blocked by the bottom surface of the fixing seat 3. A rotating rod 5 is vertically inserted on the fixing seat 3, And the rotating rod 5 is set through the fixed seat 3, and the bottom end of the rotating rod 5 is horizontally equipped with a wing plate 6, and the two ends of the wing plate 6 are connected with a stainless steel scraper 4, and the stainless steel scraper 4 is connected to the inner side wall of the chimney 1. The distance is L: 5mm≤L≤10mm, and the thickness of the stainless steel scraper 4 is S: 0.2mm≤S≤0.5mm. When the rotating ro...

Embodiment 2

[0037] refer to Image 6 , a self-cleaning chimney, including a chimney 1, two mounting rods 2 are symmetrically fixedly connected to the inner wall of the chimney 1, and a fixing seat 3 is installed between the two mounting rods 2, and the top and bottom ends of the fixing seat 3 are both An inclination angle of 45 degrees is provided upside down, and a rotating rod 5 is inserted vertically on the fixing seat 3, and the rotating rod 5 is arranged through the fixing seat 3, and the bottom end of the rotating rod 5 is horizontally equipped with a wing plate 6, and the two sides of the wing plate 6 Both ends are connected with a stainless steel scraper 4, and the bottom ends of the two stainless steel scrapers 4 are also connected with a wing plate 6.

[0038] The difference from Embodiment 1 is that the stainless steel scraper 4 is in contact with the inner wall of the chimney 1, and the thickness of the stainless steel scraper 4 is S: 0.5mm≤S≤1mm. When the rotating rod 5 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com