Heat pipe cooling nuclear reactor power system based on uranium hydrogen yttrium fuels and dynamic thermoelectric conversion

A thermoelectric conversion and nuclear reactor technology, applied in the field of nuclear power, can solve the problems of coolant loss accidents, failure to fundamentally eliminate coolant loss accidents, increase in system quality, volume and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

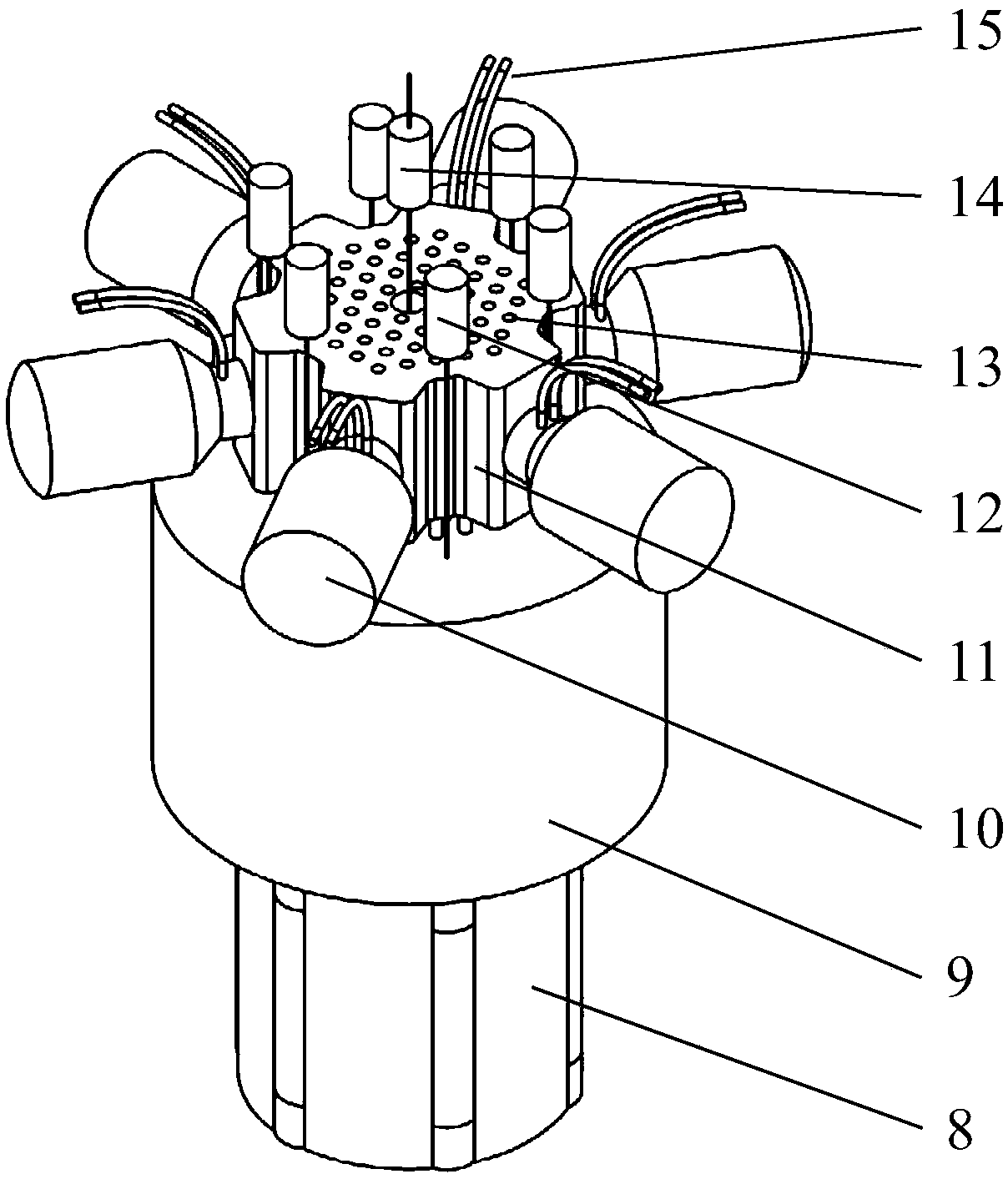

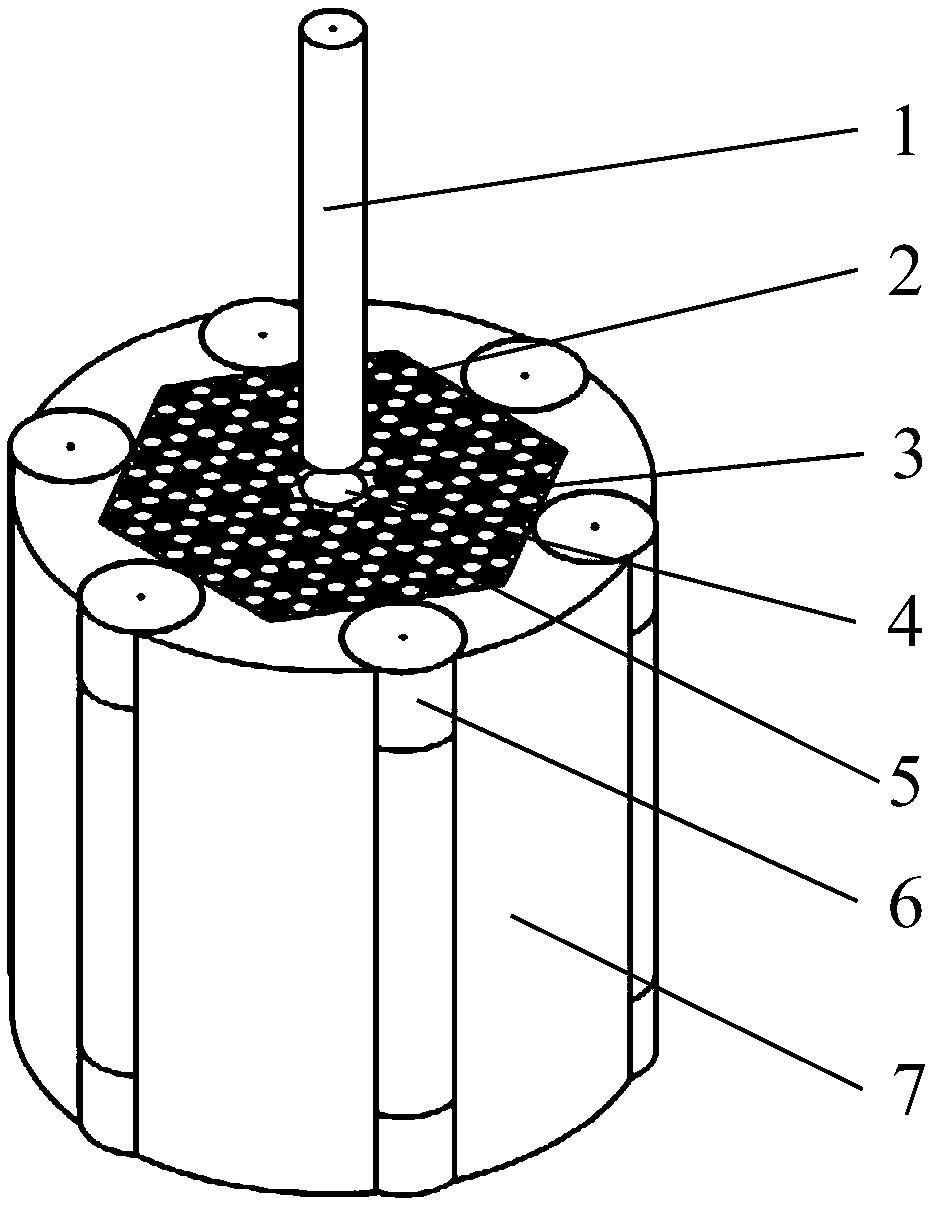

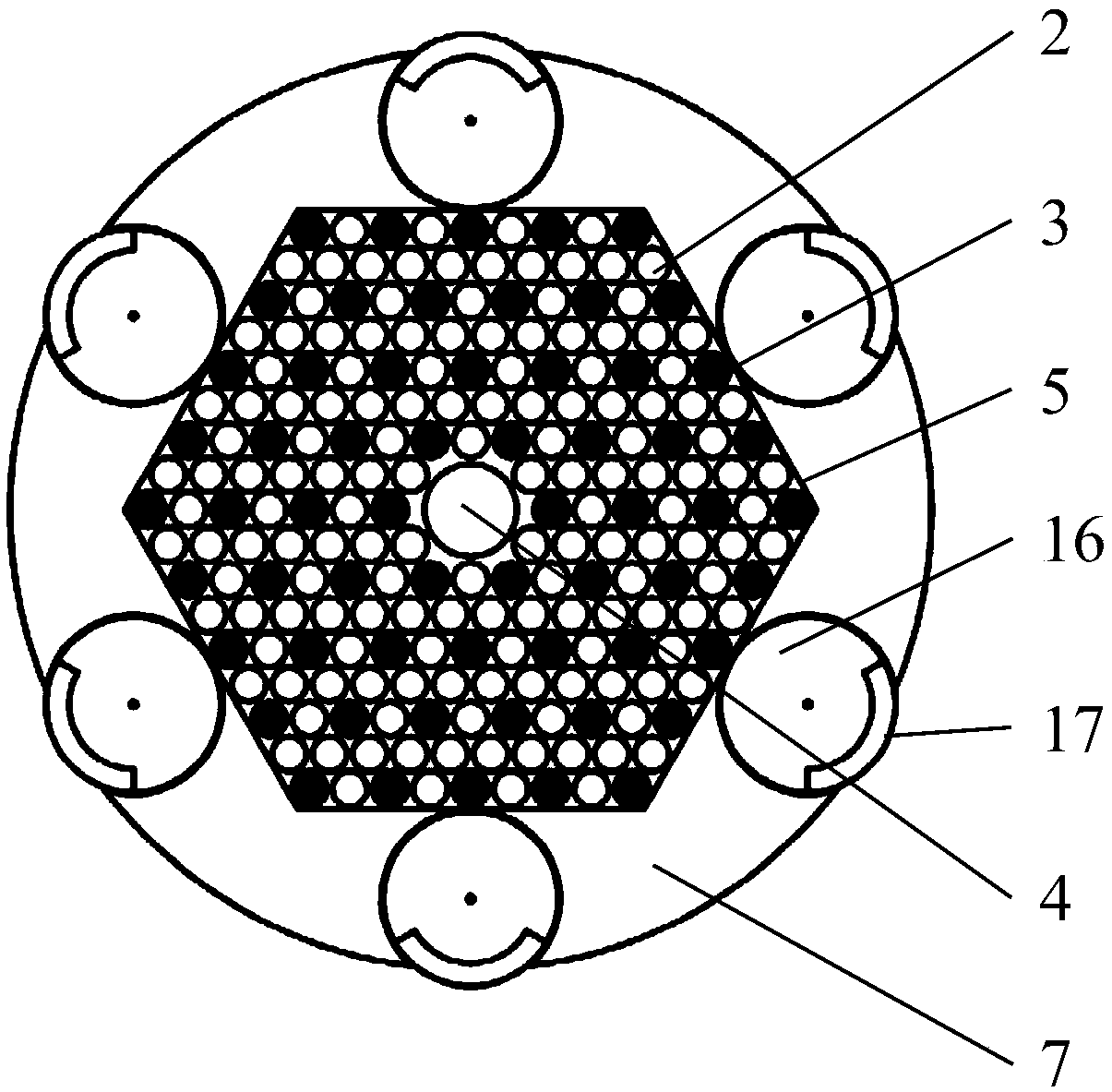

[0024] Such as figure 1 As shown, the present invention provides a heat pipe cooling nuclear reactor power system based on uranium hydrogen yttrium fuel and dynamic thermoelectric conversion, including a heat pipe 13, a reactor 8 arranged inside the shield 9, and a control drum drive arranged outside the shield 9 Mechanism 12, heat exchanger 11 and safety rod driving mechanism 14; one end of the heat pipe 13 extends into the heat pipe tunnel 3 of the reactor 8, and the other end passes through the shield 9 and is inserted into the heat exchanger 11; the heat exchanger 11 is connected to the free-piston Stirling generator 10; the control drum driving mechanism 12 and the safety rod driving mechanism 14 are drivingly connected to the control drum 6 and the safety rod 1 of the reactor 8 respectively. The heat pipe 13 is a liquid metal heat pipe. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com