High-temperature testing probe, device and method for entrained flow gasifier

A technology for testing devices and testing methods, which is applied to measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, etc., which can solve the problems of large errors, short measurement life, and low allowable temperature. Achieve high precision, improve test accuracy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

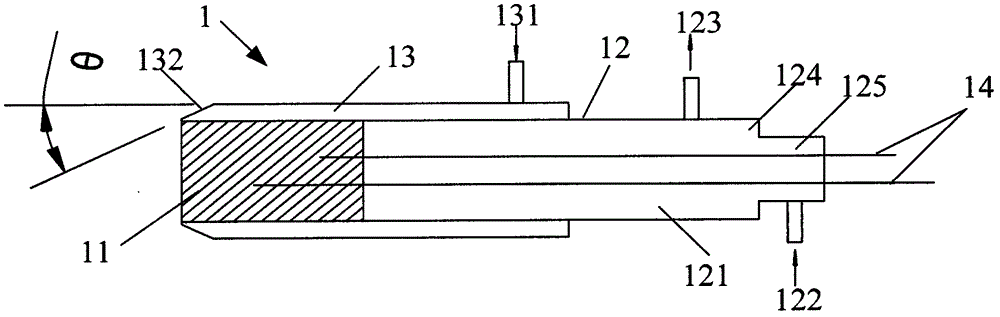

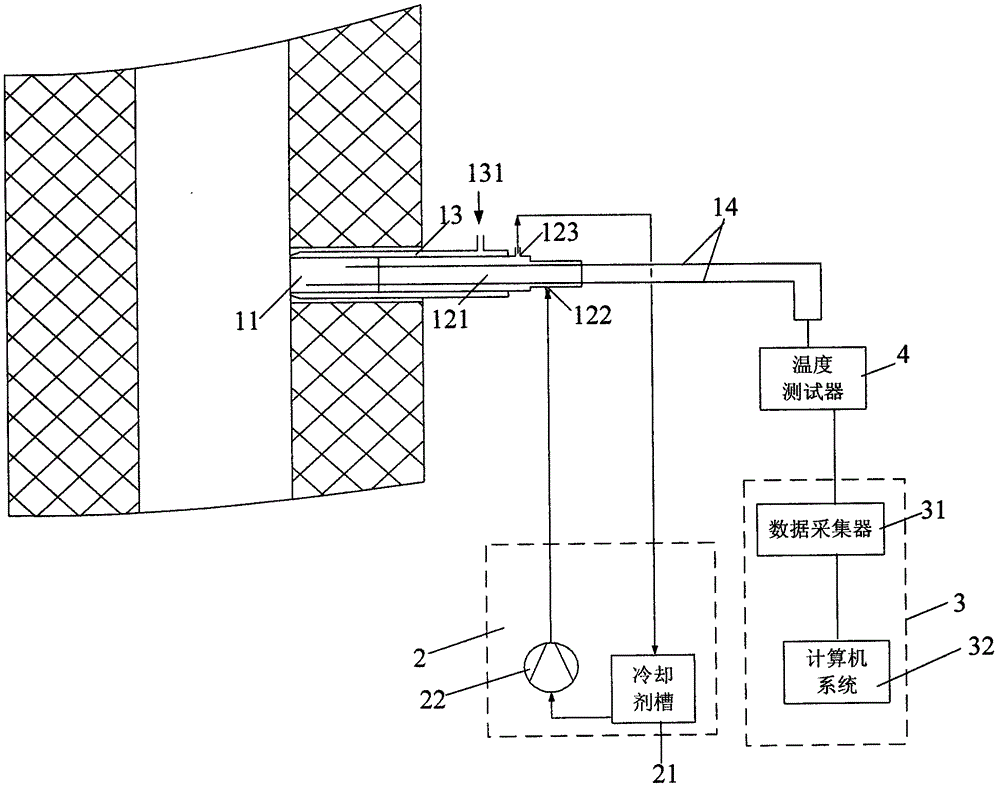

[0091] The high temperature test device for entrained bed gasification furnace of the present invention is used to directly measure the temperature in the chamber of entrained bed gasifier.

[0092] Two thermocouples are set inside the high temperature measurement probe, here we choose K-type thermocouple, and the inner core material of the high temperature probe is Inconel625.

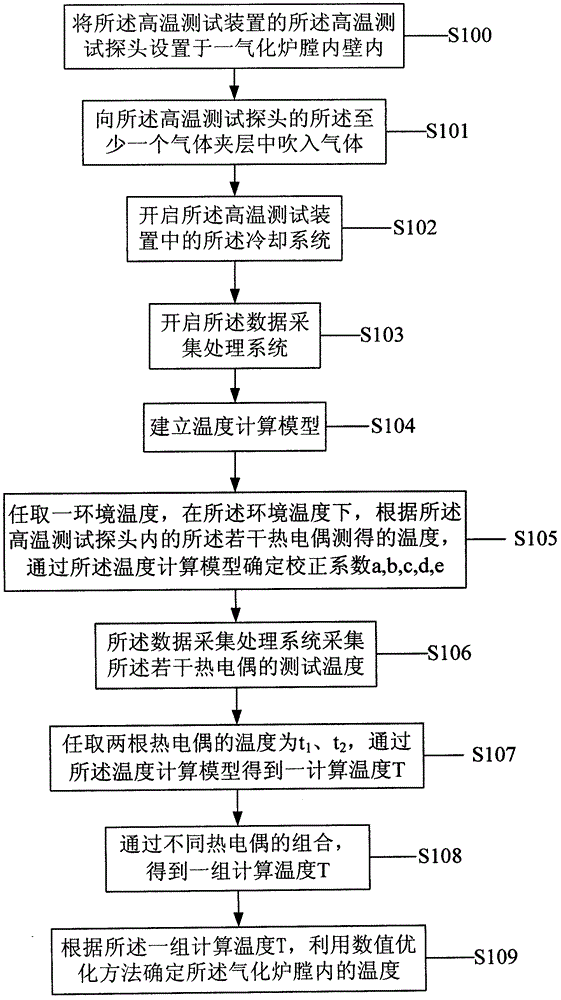

[0093] First, a high-temperature tube furnace is used to calibrate the relevant temperature correction coefficients, and the accuracy of the temperature measurement of the present invention under the condition of no ash and slag is checked. Put the high-temperature test probe into the constant temperature zone of the tube furnace for heating. The temperature in the constant temperature zone of the tube furnace is measured by a B-type thermocouple. The temperature measurement range is 1000-1500°C, and the temperature interval is 50°C. Record the relevant tube furnace temperature T g , and the inner co...

Embodiment approach 2

[0098] The high temperature test device for entrained bed gasification furnace of the present invention is used to directly measure the temperature in the chamber of entrained bed gasifier.

[0099] In order to further improve the temperature measurement accuracy of the high temperature measurement device, the inner core of the high temperature test probe is provided with n K-type thermocouples along the axial direction, 2<n≤10, to reduce the measurement error caused by improper placement of thermocouples, The inner core material of the high temperature test probe is made of Inconel625.

[0100] The relevant temperature correction coefficients of the temperature calculation model are obtained after the high-temperature tube furnace is calibrated.

[0101] Using diesel oil, Beisu pulverized coal and oxygen as the gasification medium, the temperature in the gasification furnace is measured with a K-type armored thermocouple. Use argon purge gas to protect the measuring surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com