Battery module

A technology of battery modules and modules, which is applied to battery pack components, secondary batteries, small-sized batteries/battery packs, etc., and can solve problems affecting battery quality, unguaranteed welding quality, and poor bonding performance, etc. problems, to achieve the effects of diversified splicing methods, convenient structure disassembly and assembly, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

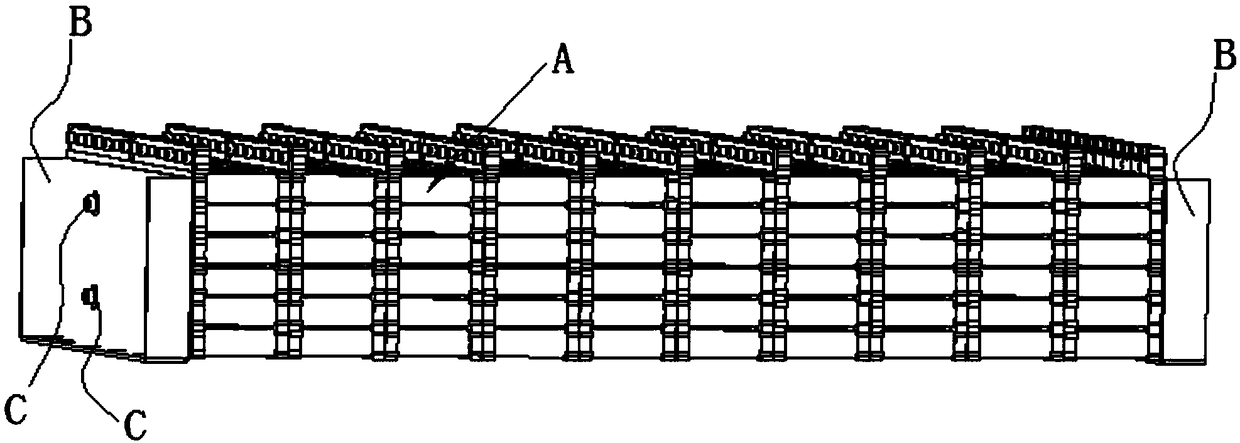

[0060] Embodiment 1: a battery module, such as Figure 2-Figure 6 with Figure 12-Figure 20 As shown, it includes a plurality of single battery modules A, an external frame B and a connecting shaft C, the external frame B is located on the left and right sides of the battery module, and the connecting shaft C connects the multiple single cells The module and the external cage are fixed in series, and the connection shaft, multiple single battery molds and the external cage are fixed through the nuts at both ends of the connecting shaft;

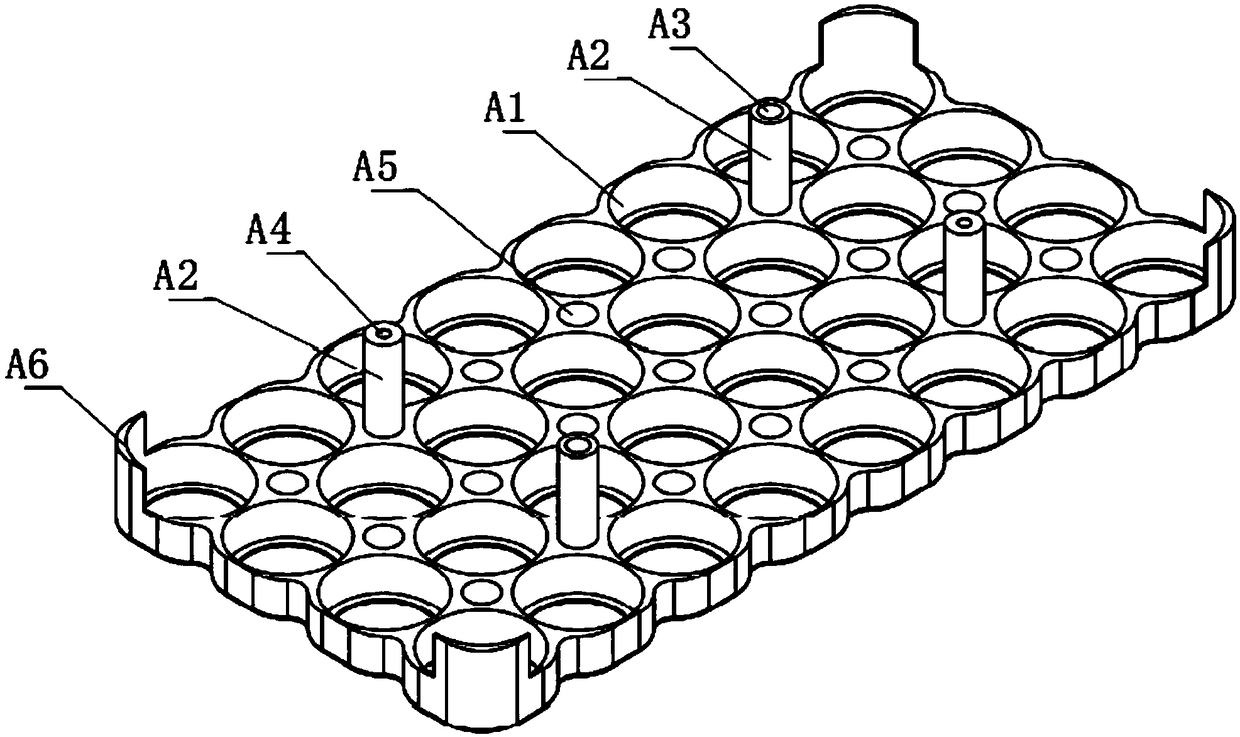

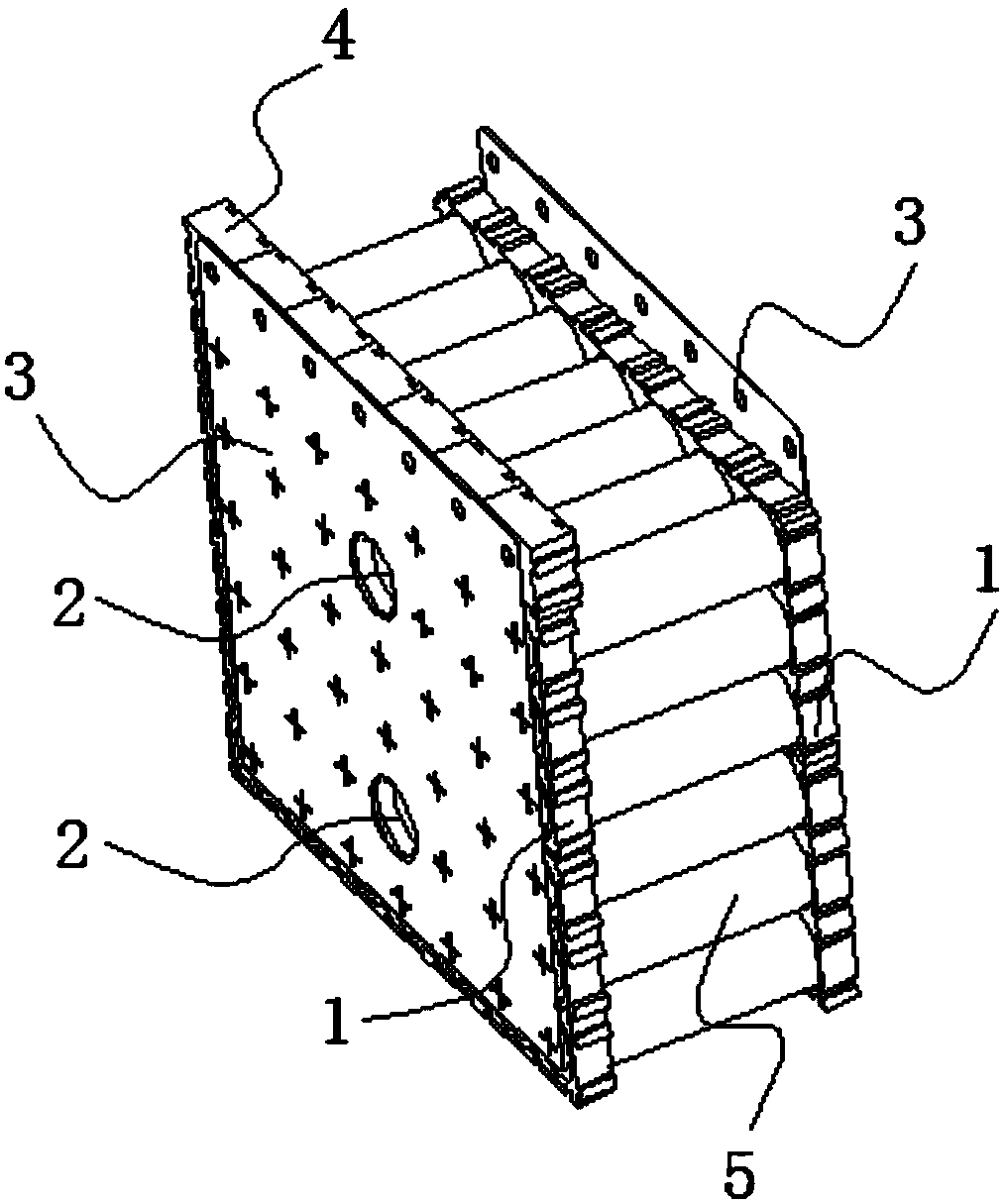

[0061] Each single battery module A includes two battery fixing substrates 1, a hollow connecting column 2 connecting the two battery fixing substrates, a bus bar 3 and a bus bar fixing frame 4, and the bus bar 3 and the bus bar fixing frame 4 fixedly connected, the bus bar fixing frame 4 is plugged and fixed with the battery fixing substrate 1;

[0062] On either side of the two adjacent sides of the battery fixing substrate 1, a number of...

Embodiment 2

[0079] Embodiment 2: a battery module, such as Figure 7-Figure 20 As shown, the rest is the same as that of Embodiment 1, the difference is that: the structure for realizing the insertion and fixing of the busbar fixing frame and the battery fixing substrate is: the busbar of this fixing method is L-shaped, and the busbar The rear side wall of the fixing frame is provided with a second plug port 45, and the second plug port 45 is formed by extending downward from the upper end of the rear side wall of the bus bar fixing frame, and the upper end of the battery fixing base plate is provided with a second plug port. Plug posts with matching interfaces.

[0080] The second socket 45 is a socket with a closed end.

[0081] The working principle of the present invention is as follows:

[0082] First use the plug-in grooves and plug-in bumps of the battery-fixed base plate to arbitrarily splice out the size of the required battery-fixed plate, and place the lithium battery in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com