Hot-dip galvanized steel sheet

一种热浸镀锌钢板、钢板的技术,应用在热浸镀工艺、热处理炉、热处理设备等方向,能够解决韧性差、钢板韧性下降等问题,达到耐氢脆性优良、高拉伸强度和屈服比的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

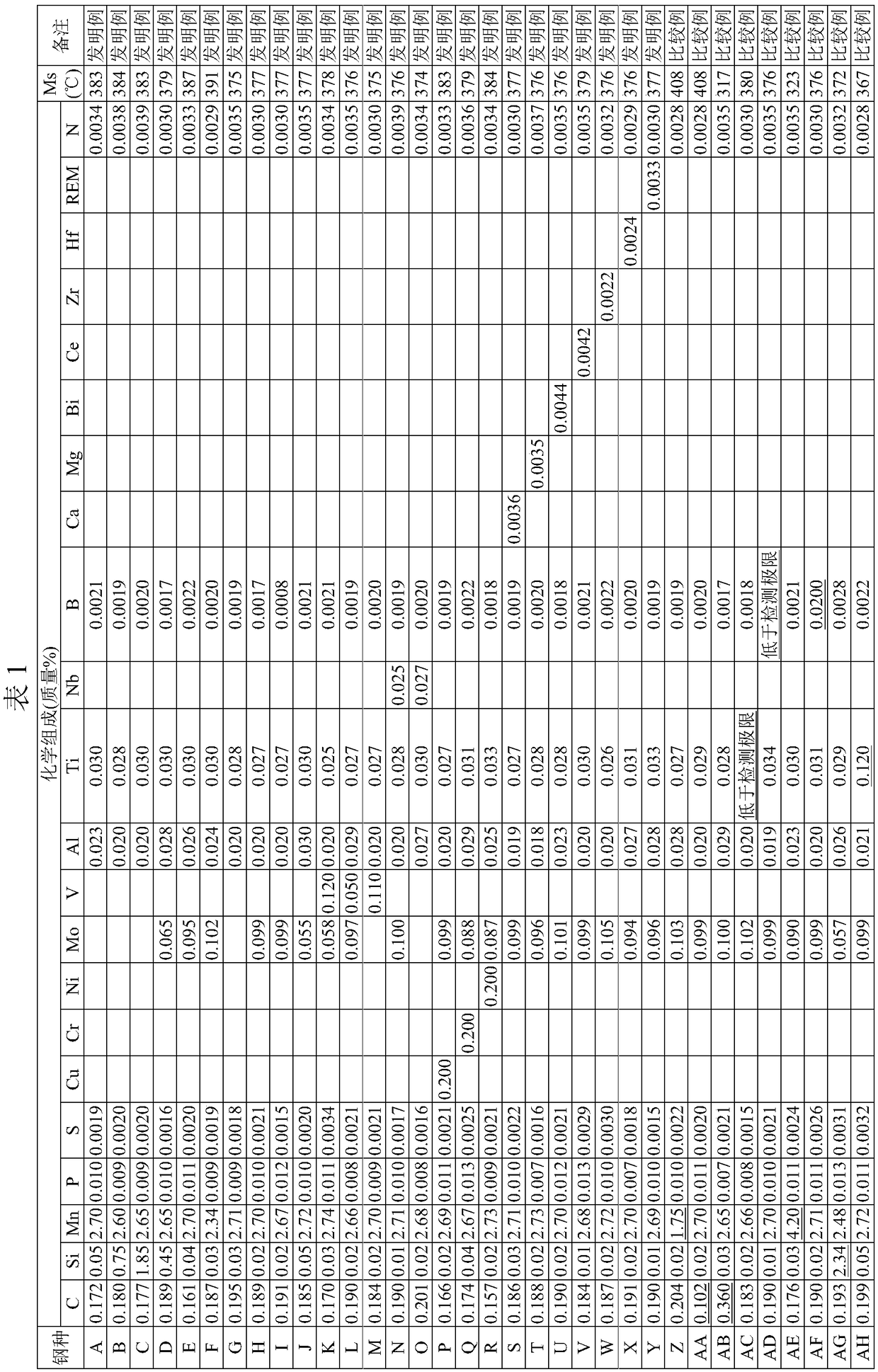

[0158] Steel having the chemical composition shown in Table 1 was melted to form a slab, and the slab was hot-rolled under the hot-rolling conditions shown in Table 2 to form a hot-rolled steel sheet with a thickness of 3 mm. After pickling this hot-rolled steel sheet, it cold-rolled under the cold-rolling conditions (reduction ratio) shown in Table 2, and it produced the cold-rolled steel sheet of thickness 1.2mm. The empty column in Table 1 indicates that the content of this element is lower than the detection limit, and the rest is Fe and impurities. Underlines in Table 1 indicate that the values are outside the scope of the present invention.

[0159]

[0160] Table 2

[0161]

[0162] R1: the total reduction rate from below 1050°C to the final pass

[0163] R2: The reduction rate of the final pass

[0164] FT: temperature of the final pass

[0165] Δt: Elapsed time from the end of finishing rolling to the beginning of cooling

[0166] For the obtained cold-roll...

Embodiment 2

[0190] Some of the steel sheets with the chemical compositions shown in Table 1 were hot-rolled under the hot-rolling conditions shown in Table 6 to obtain hot-rolled steel sheets with a thickness of 3 mm. After pickling the hot-rolled steel sheets, cold rolling was performed under the cold-rolling conditions (reduction ratio) shown in Table 6 to obtain cold-rolled steel sheets with a thickness of 1.2 mm.

[0191] Table 6

[0192]

[0193] R1: the total reduction rate from below 1050°C to the final pass

[0194] R2: The reduction rate of the final pass

[0195] FT: temperature of the final pass

[0196] Δt: Elapsed time from the end of finishing rolling to the beginning of cooling

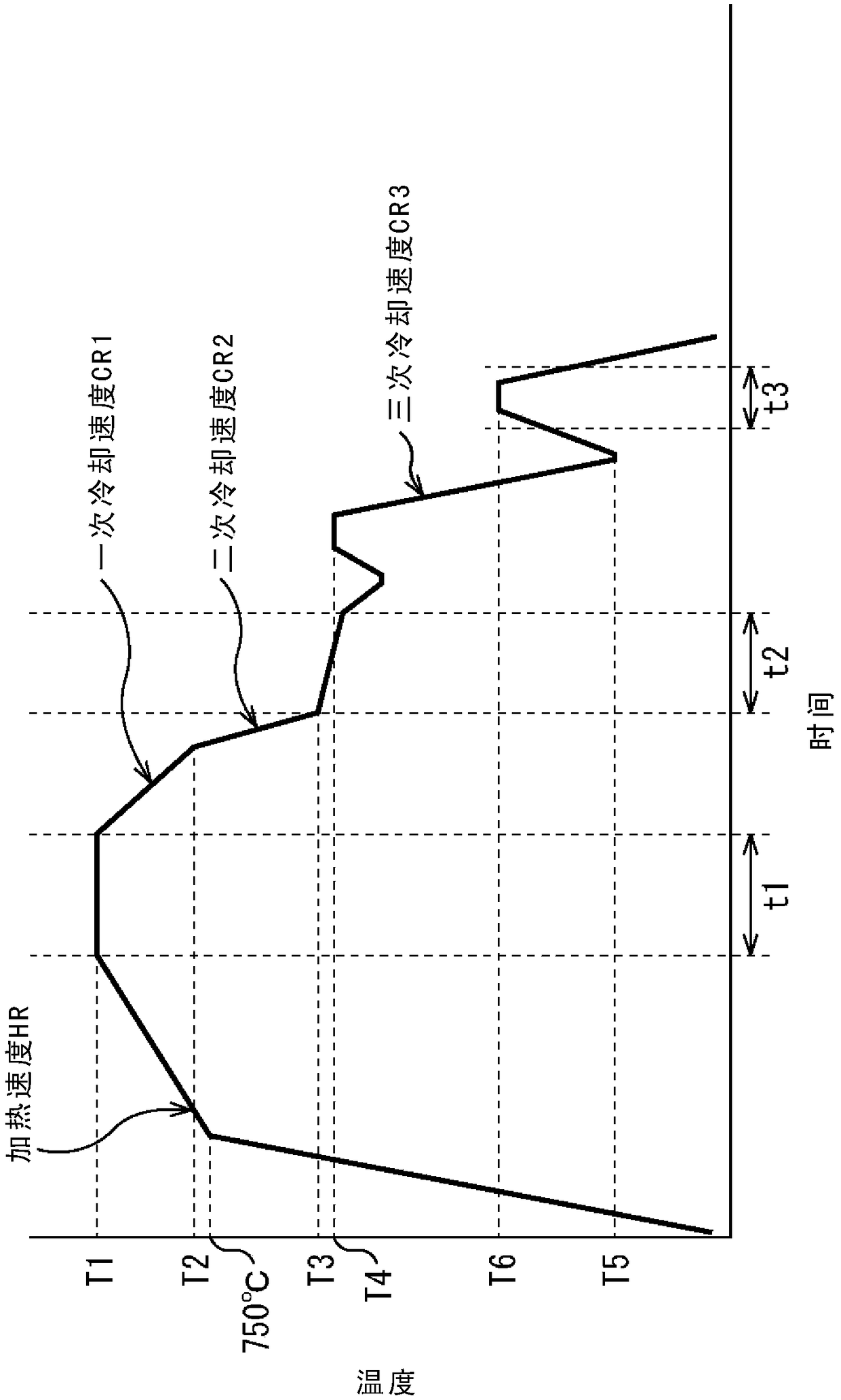

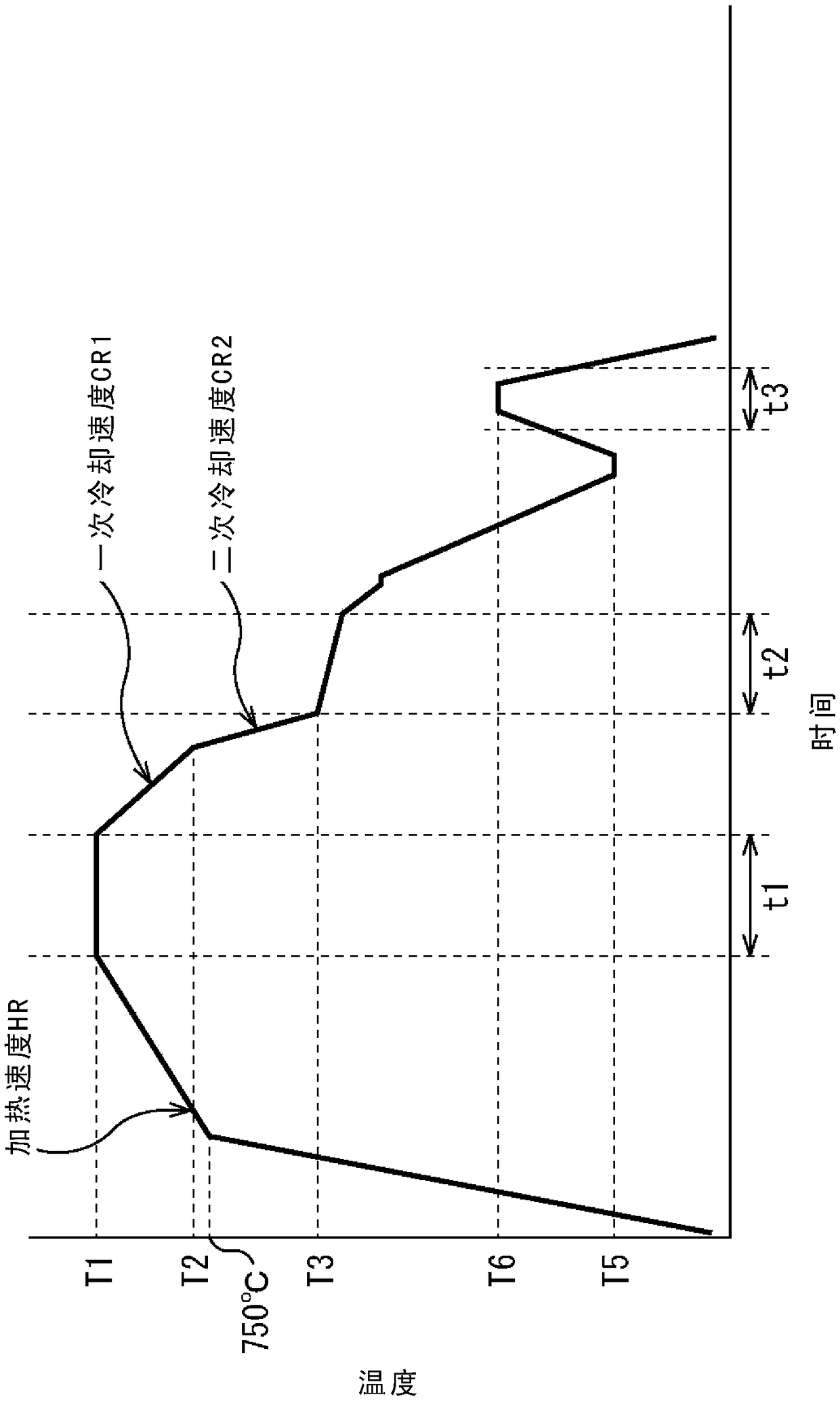

[0197] For the obtained cold-rolled steel plate in figure 2 and heat treatment under the heat treatment conditions shown in Table 7, and then in figure 2 Hot-dip galvanizing was performed under the coating conditions shown in Table 7. Furthermore, in figure 2 Under the conditions shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| dislocation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com