Device for automatically combing bent end of straight rice vermicelli

A technology of straight rice noodles and elbows, which is applied in the field of automatic carding devices for straight rice noodles and elbows. It can solve the problems of complex structure, low yield of straight noodles, and limited quality of loose silk, so as to achieve simple structure of the device and reduce production. The effect of simple cost and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment the present invention is described in further detail:

[0029] The following examples will help to further understand the present invention, but do not limit the content of the present invention.

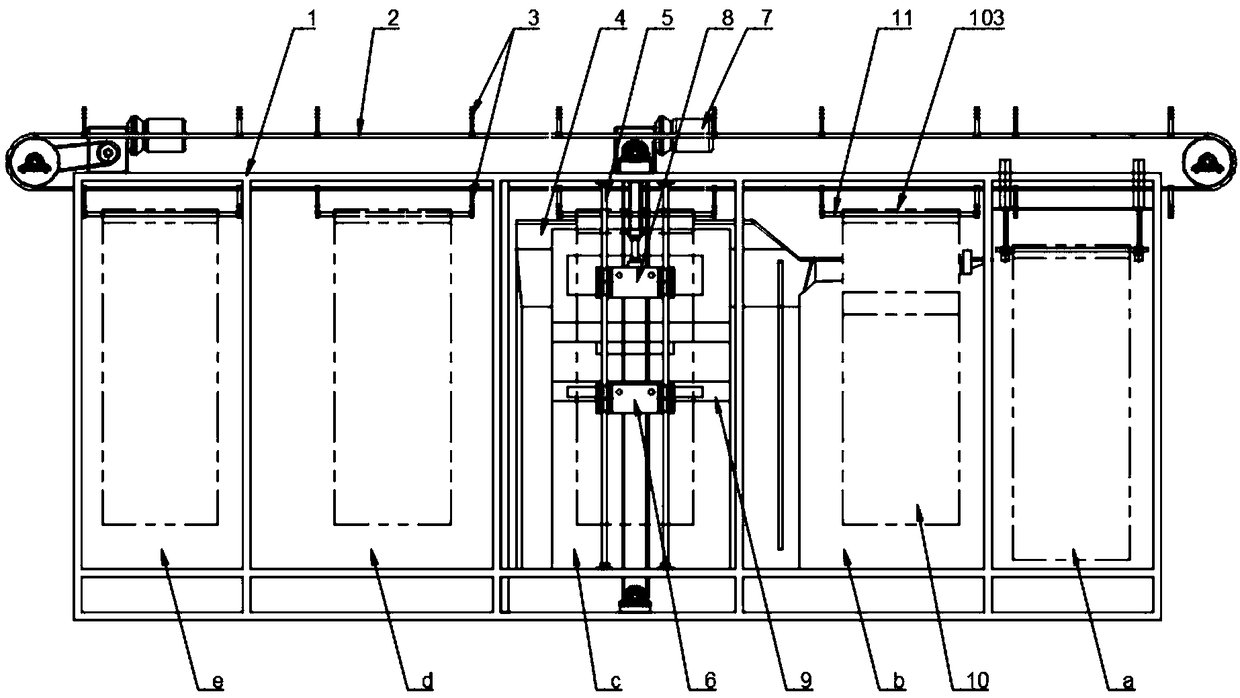

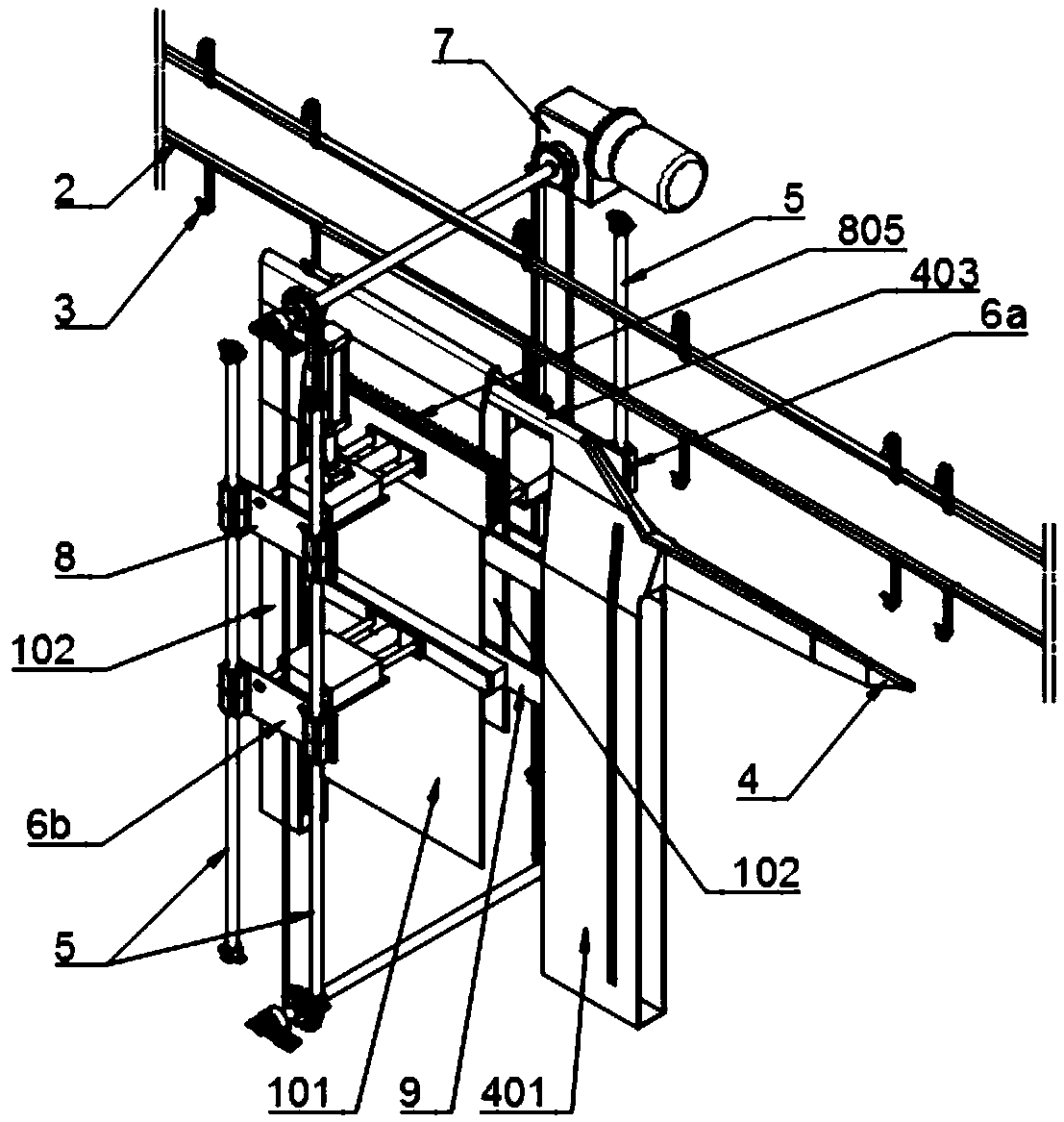

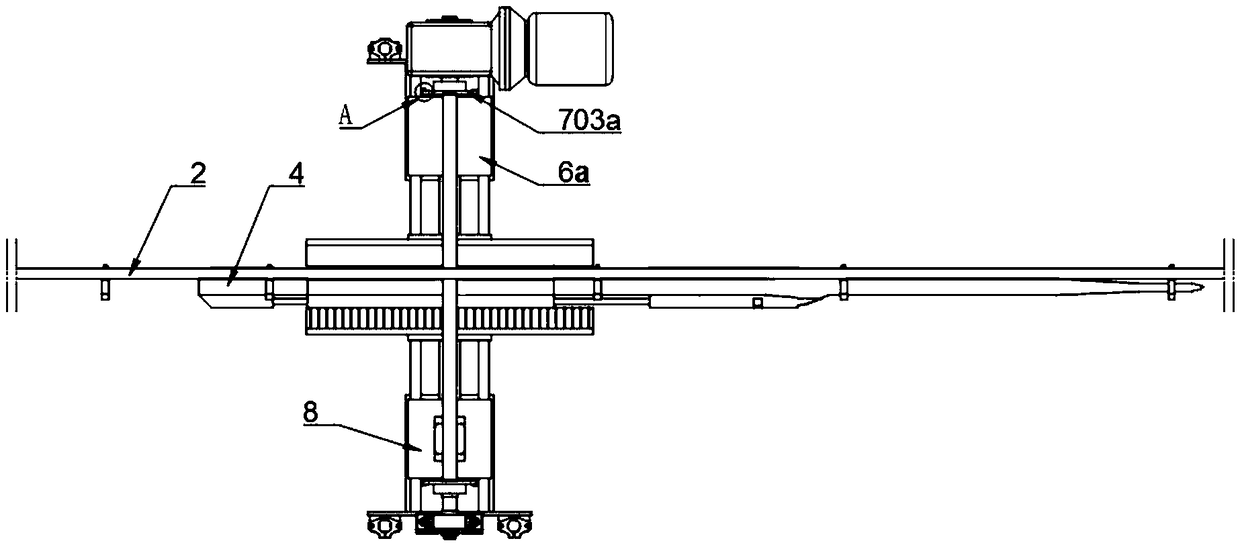

[0030] Such as figure 1 , 2 As shown, a kind of straight rice vermicelli elbow automatic carding device disclosed by the present invention includes a frame 1, a hanging unit a arranged on the frame 1, a piece unit b, an elbow carding unit c, a straight hanging Carding unit d, outgoing hanging unit e, powder hanging conveyor 2; rod-through unfolding frame 4 arranged in slicing unit b and elbow carding unit c; hanging rod 11 placed in hook 3 on powder hanging conveyor 2 After the powder hanging 10 suspended on the hanging rod 11 is divided into the powder hanging front piece 101 and the powder hanging back piece 102 by the corresponding device of the penetrating rod unfolding frame 4 in the piece unit, it is sent to the elbow by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com