Accelerated conveying device of automatic leveling and sizing collection system of cigarette carton skin

A technology of conveying device and collecting system, which is applied to stack receiving device, transportation and packaging, packaging, etc., can solve the problems of wasting manpower, difficult to meet the leveling requirements, and long time for flattening equipment, and achieves the improvement of the scope of application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

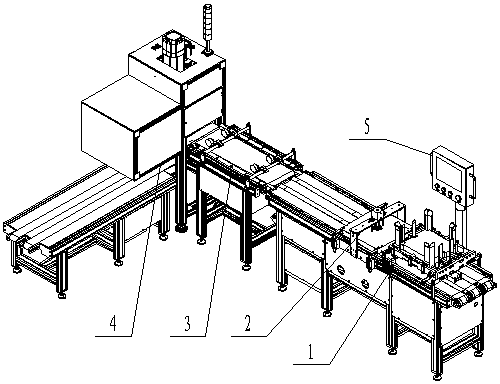

[0046] Such as Figure 1 to Figure 18 As shown, the automatic leveling and shaping collection system for cigarette cartons in this embodiment includes a retrieving device 1 , an automatic leveling and hot-pressing device 2 , an accelerating conveying device 3 , a receiving and sorting device 4 and an electric control device 5 .

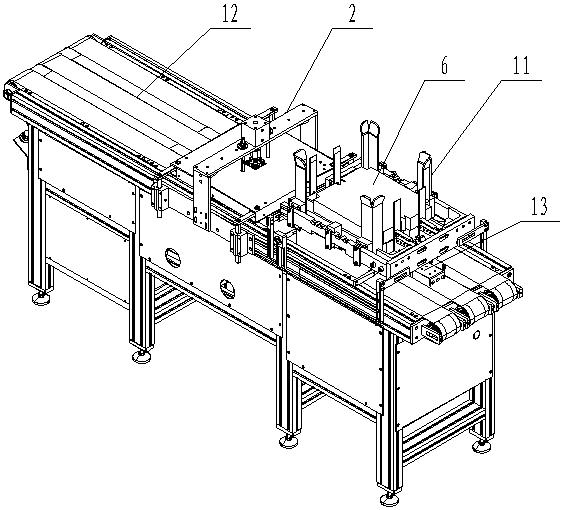

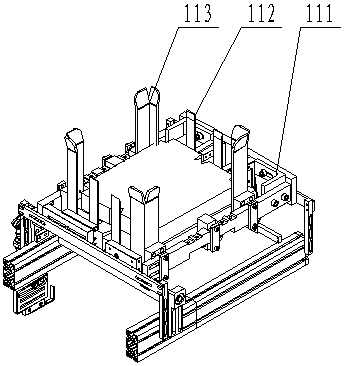

[0047] The retrieving device is made up of a material storehouse 11, a conveying structure 12 and a sheet retrieving structure 13. Wherein the material storehouse 11 is positioned at the top of the conveying structure 12, and the box skins 6 to be processed are placed in the material storehouse 11 in piles, and the outer surface of the box skins 6 is arranged upwards, which is convenient for the single-sheet retrieving structure 13 to take materials; The retrieving structure 13 is arranged below the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com