Outdoor scratch-resistant powder coating

A powder coating, scratch-resistant technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of coating film surface scratches, coating damage, and reducing the service life of substrates, etc., to achieve good leveling , Excellent scratch resistance, smooth coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

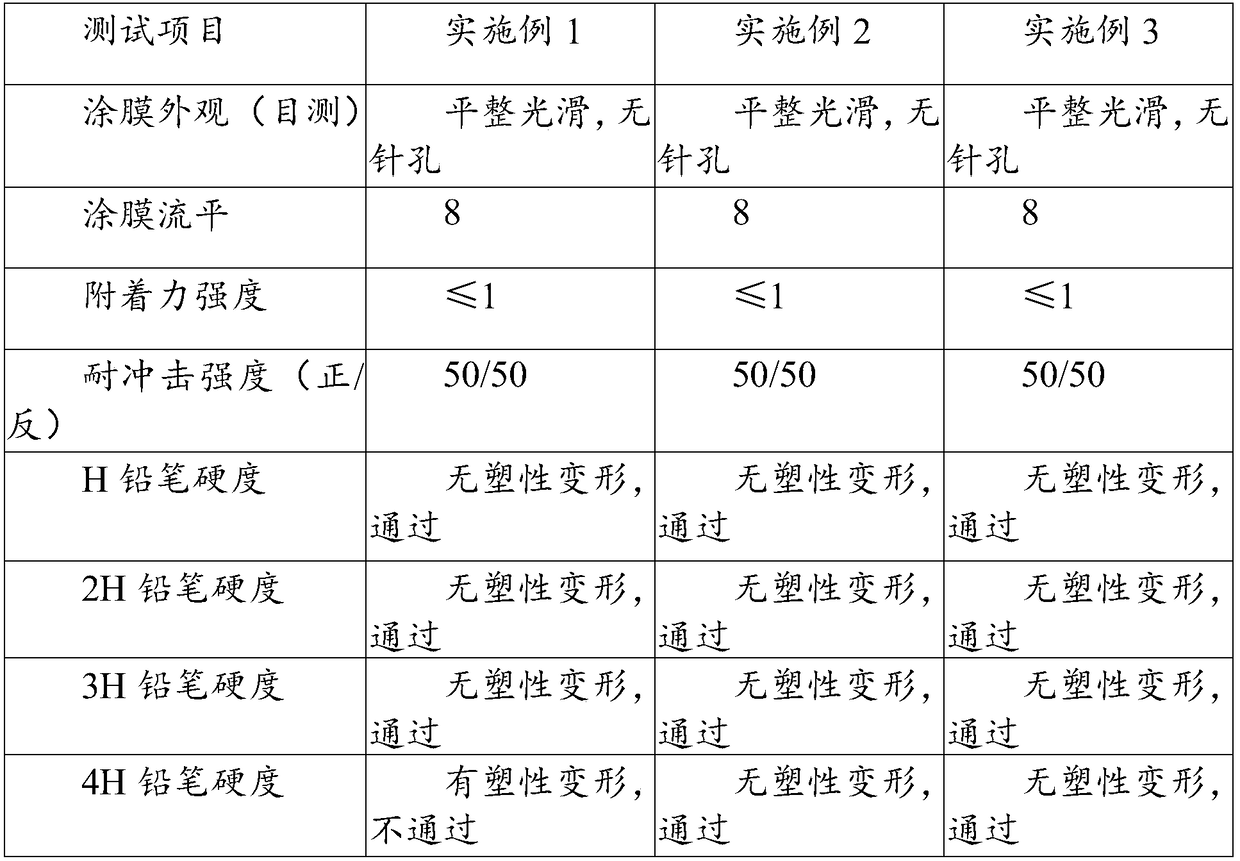

Embodiment 1

[0018] (1) Put 100g of polyester resin and 80g of silicone powder in parts by weight into a mixing tank and pre-mix evenly, then melt and extrude the pre-mixed raw materials through a twin-screw extruder, and press them into tablets. The output zone I is stable at 110°C, and the temperature in zone II is 130°C. Collect flakes and crush them to obtain silicone masterbatch products;

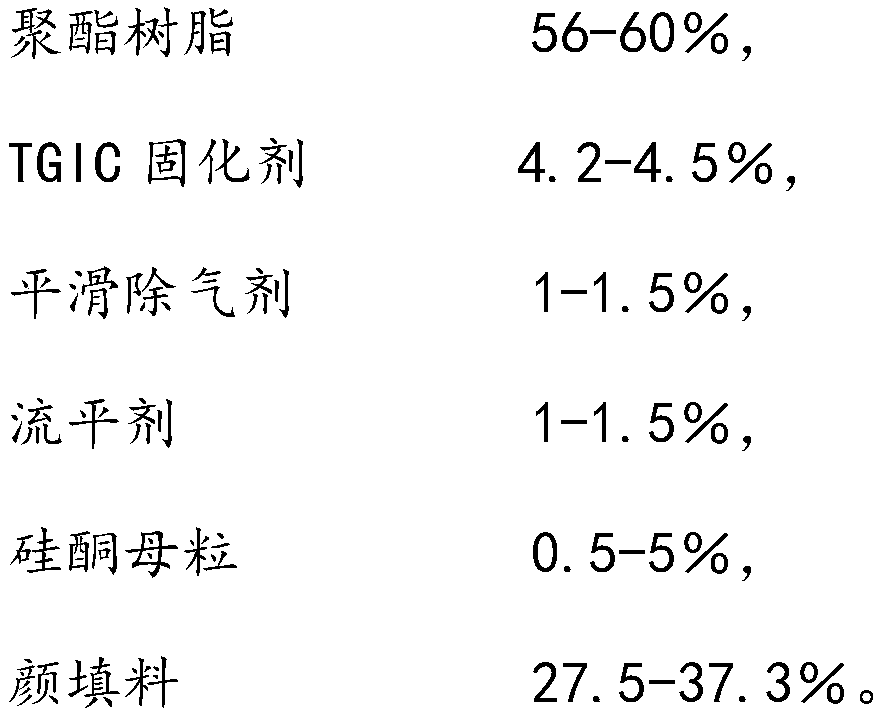

[0019] (2) An outdoor scratch-resistant powder coating made of the following components by mass percentage:

[0020] Polyester resin 56%

[0021] TGIC curing agent 4.2%

[0022] Smooth Degasser 1%

[0023] Leveling agent 1%

[0024] Silicone masterbatch 0.5%

[0025] Filler 25.3%

[0026] Pigment 12%

[0027] Among them, the polyester resin is SJ3B from Anhui Shenjian New Material Co., Ltd.; the leveling agent is PV88 from German Dexinli Chemical; the filler is precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.; the pigment is ZR940+ from Jiangsu Zhentai Chemical Co., Ltd.;

...

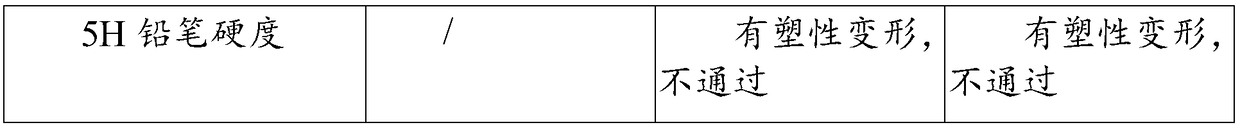

Embodiment 2

[0030] (1) Put 100g of polyester resin and 120g of silicone powder in parts by weight into a mixing tank and pre-mix evenly, then melt and extrude the pre-mixed raw materials through a twin-screw extruder, and press them into tablets. The output zone I is stable at 110°C, and the temperature in zone II is 130°C. Collect flakes and crush them to obtain silicone masterbatch products;

[0031] (2) An outdoor scratch-resistant powder coating made of the following components by mass percentage:

[0032] Polyester resin 58%

[0033] TGIC curing agent 4.3%

[0034] Smooth Degasser 1.7%

[0035] Leveling agent 1.7%

[0036] Silicone masterbatch 1.2%

[0037] Filler 20.5%

[0038] Pigment 12.6%

[0039] Among them, the polyester resin is SJ3B from Anhui Shenjian New Material Co., Ltd.; the leveling agent is PV88 from German Dexinli Chemical; the filler is precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.; the pigment is ZR940+ from Jiangsu Zhentai Chemical Co., Lt...

Embodiment 3

[0042] (1) Put 100g of polyester resin and 150g of silicone powder in parts by weight into a mixing tank and pre-mix evenly, then melt and extrude the pre-mixed raw materials through a twin-screw extruder, and press them into tablets. The output zone I is stable at 110°C, and the temperature in zone II is 130°C. Collect flakes and crush them to obtain silicone masterbatch products;

[0043] (2) An outdoor scratch-resistant powder coating made of the following components by mass percentage:

[0044] Polyester resin 60%

[0045] TGIC curing agent 4.5%

[0046] Smooth Degasser 1.5%

[0047] Leveling agent 1.5%

[0048] Silicone masterbatch 5%

[0049] Filler 17.9%

[0050] Pigment 9.6

[0051] Among them, the polyester resin is SJ3B from Anhui Shenjian New Material Co., Ltd.; the leveling agent is PV88 from German Dexinli Chemical; the filler is precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.; the pigment is ZR940+ from Jiangsu Zhentai Chemical Co., Ltd.; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com