Aqueous gloss oil for high-tolerance aluminum material and preparation method thereof

A water-based varnish and aluminum technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of decreased adhesion, shrinkage cavity, elevated temperature, etc., and achieve good adhesion and wide application Foreground, smooth and smooth effect of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

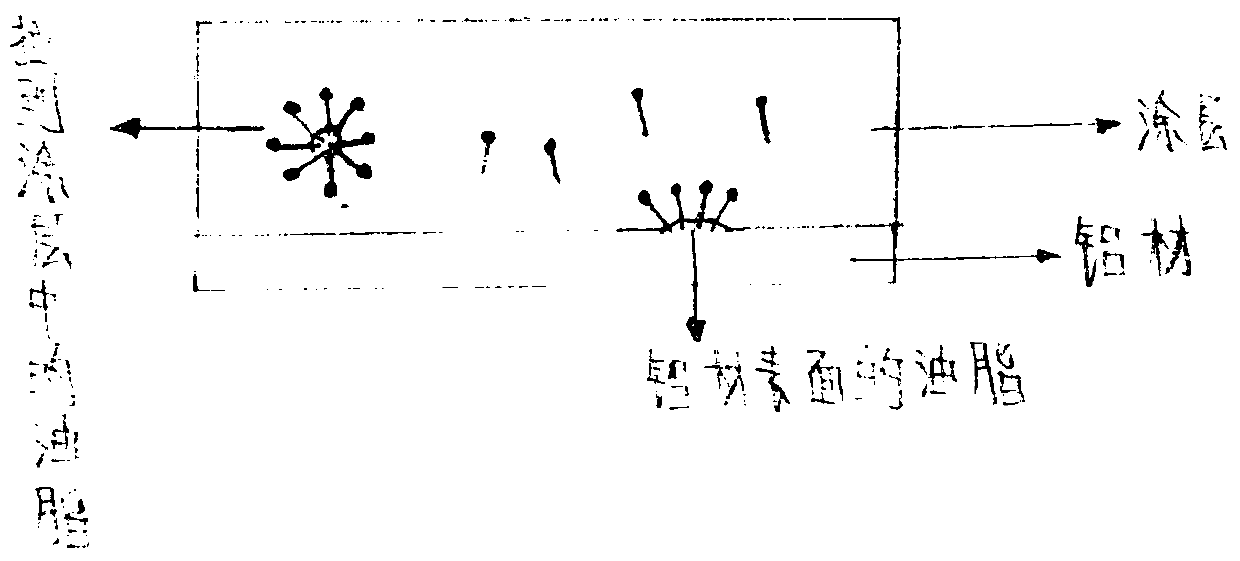

Image

Examples

Embodiment 1

[0023] A water-based varnish for aluminum with high tolerance and a preparation method thereof, comprising the following steps:

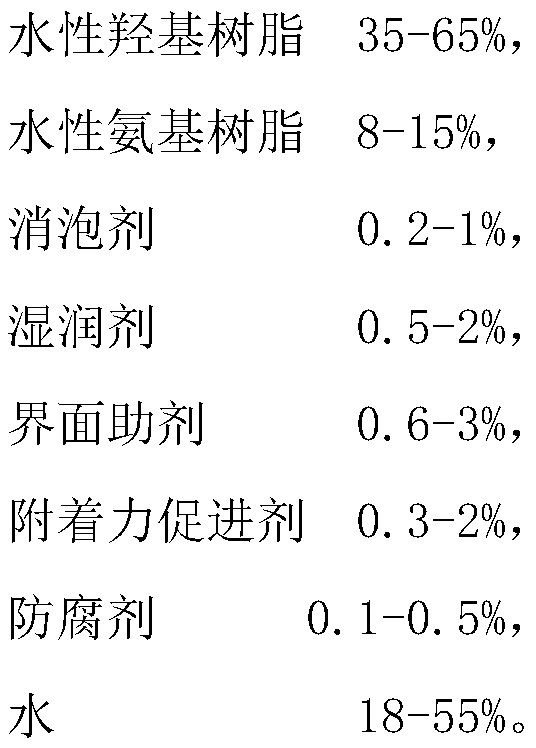

[0024] (1) Preparing raw materials: the components and weight percentages of the raw materials are as follows: 1. water-based hydroxyl acrylic resin (model is BLJ6102) 43%, 2. polymerized partially methylated melamine resin (model is CYMEL 325) 10%, 3. advanced Alcohol defoamer (3-heptanol) 0.5%, ④ acetylene glycol wetting agent 1%, ⑤ octanylphenol polyoxyethylene ether 0.6%, ⑥ aminosilane 0.6%, ⑦ BIT 0.2%, ⑧ deionized water 44.1%.

[0025] (2) Preparation process: Add components ⑧, ③, ⑦, ② into the reactor in turn, stir at a slow speed for 10 minutes, then add components ④, ⑤, ⑥, ①, and continue stirring for 20 minutes to obtain the coating.

[0026] (3) Construction method: Spray coating and roller coating can be used, and the drying condition is 5-30 minutes at 120-180°C.

[0027] Implementation column 2

[0028] A water-based varnish for alum...

Embodiment 3

[0033] A water-based varnish for aluminum with high tolerance and a preparation method thereof, comprising the following steps:

[0034] (6) Prepare raw materials: each component of raw materials and weight percent thereof are as follows: 1. water-based hydroxyl polyester resin (model is KN8245W) 35%, 2. methyl etherified melamine resin (model is CYMEL 303) 15%, 3. organosilicon disinfectant Foaming agent (model MOUSSEX S 8044) 0.2%, ④ acetylene glycol wetting agent 0.5%, ⑤ sodium dodecylbenzene sulfonate 3%, ⑥ aminosilane 2%, ⑦ BIT 0.1%, ⑧ deionized water 44.2 %.

[0035] (7) Preparation process: add components ⑧, ③, ⑦, ② into the reactor in turn, stir at a slow speed for 10 minutes, then add components ④, ⑤, ⑥, ①, and continue stirring for 20 minutes to obtain the coating.

[0036] (8) Construction method: Spray coating and roller coating can be used, and the drying condition is 5-30 minutes at 120-180°C.

Embodiment 4

[0038] A water-based varnish for aluminum with high tolerance and a preparation method thereof, comprising the following steps:

[0039] (9) Preparing raw materials: each component of the raw material and its weight percentage are as follows: 1. water-based hydroxy alkyd resin (model is FX-W6001) 65%, 2. polymerized high imino high methyl etherification melamine resin (model is CYMEL 327 ) 8%, ③ higher alcohol defoamer (3-heptanol) 1%, ④ acetylene glycol wetting agent 2%, ⑤ sorbitan trioleate 2%, ⑥ aminosilane 0.3%, ⑦ BIT 0.5 %, ⑧ deionized water 21.2%.

[0040] (10) Preparation process: add components ⑧, ③, ⑦, ② into the reactor in turn, stir at a slow speed for 10 minutes, then add components ④, ⑤, ⑥, ①, and continue stirring for 20 minutes to obtain the coating.

[0041] (11) Construction method: Spray coating and roller coating can be used, and the drying condition is 5-30 minutes at 120-180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com