Test method for external pressure resistance of steel pipe for submarine pipeline

A test method and technology for steel pipes, which are used in the application of stable tension/pressure to test the strength of materials, use of liquid/vacuum for liquid tightness measurement, measurement devices, etc. The test of external pressure resistance of steel pipes for submarine pipelines has achieved the effect of optimizing design specifications, ensuring strength, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

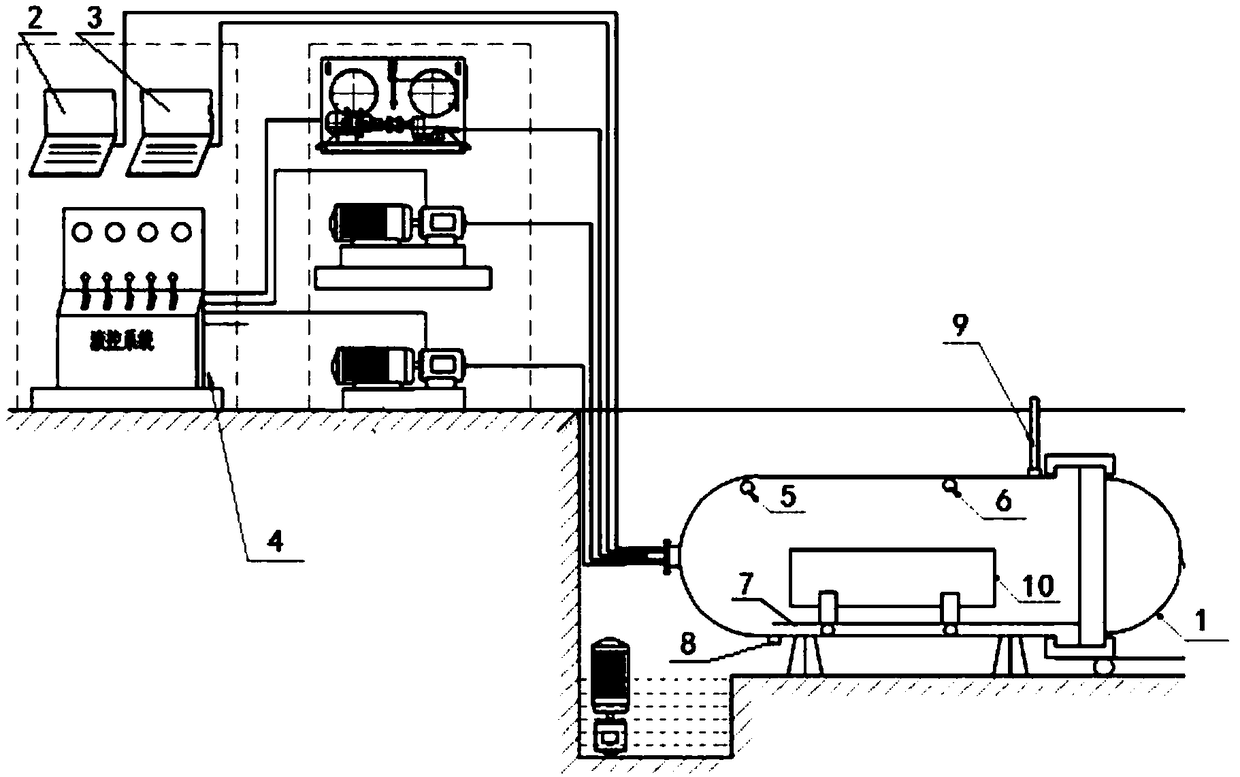

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

[0035] The present invention takes the compression performance test of X70 φ914×36.5mm straight seam submerged arc welded steel pipe under the external pressure of 35MPa as an example in the deep sea pipeline.

[0036] (1) Select test equipment

[0037] The test equipment is a deep-sea high-pressure simulation test chamber 1, which is connected with a data acquisition system 2, a video monitoring system 3 and a hydraulic control system 4; figure 1 It can be seen that the deep-sea high-pressure simulation test cabin 1 is placed in the test pit, and the top of the deep-sea high-pressure simulation test cabin 1 is equipped with a high-voltage camera 5 and a high-voltage lighting lamp 6, and the bottom is provided with an in-chamber slide rail 7 for installing steel pipe specimens. And discharge port 8, the outside is equipped with exhaust port safety valve 9.

[0038] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com