Polishing device having pad which has grooves and holes

A polishing device and polishing pad technology, which are applied to wheels with flexible working parts, machine tools with surface polishing, grinding/polishing equipment, etc., can solve the problem that the amount of polishing agent 16 cannot be effectively reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

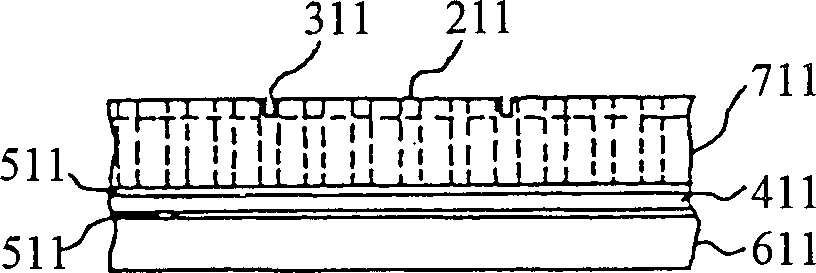

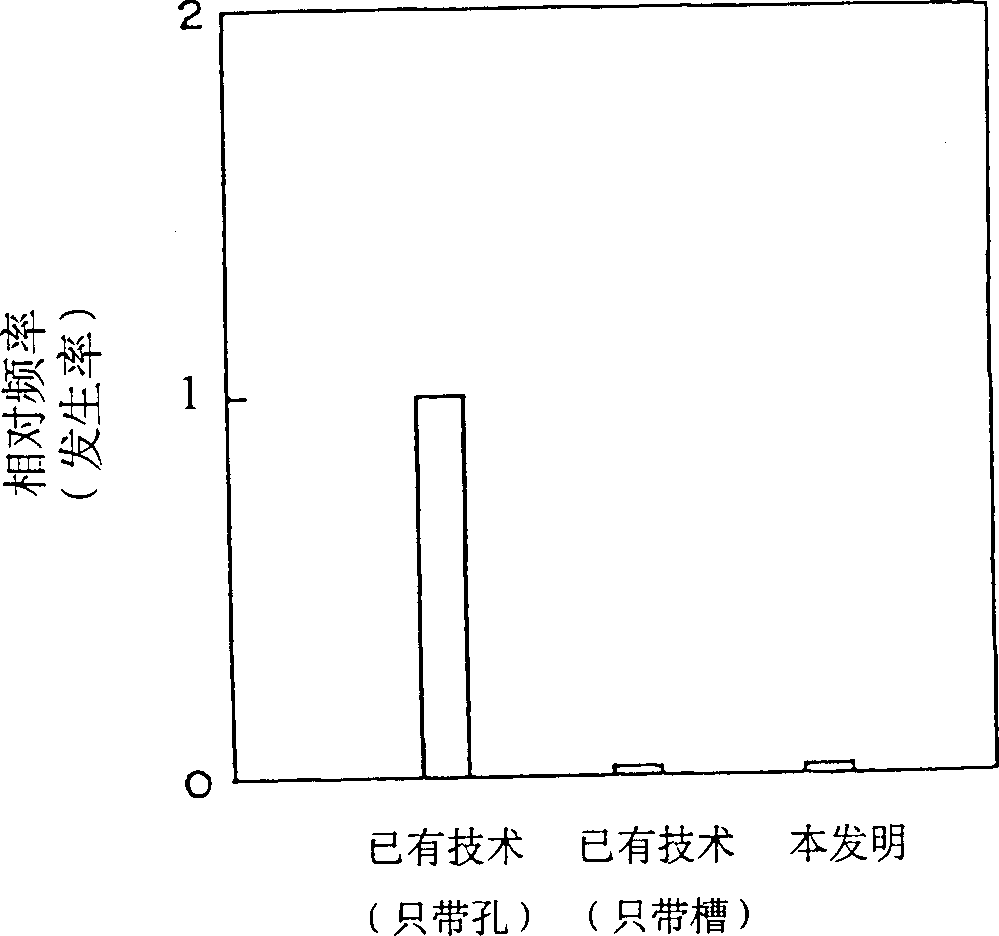

[0050]In the polishing pad as a preferred embodiment of the present invention, the required minimum number of grooves are formed on the polishing pad with holes for holding a polishing agent. These grooves are used to reduce the tight seal and to make the excess loading of the edge part of the semiconductor chip less, so their pitch is several times larger than that of the prior art grooves in FIG. 24 . That is, the grooves of the present invention are not effective in supplying polishing compound to the semiconductor wafer, but are effective in supplying atmospheric air to the holes.

[0051] Except for the shape of the polishing pad, the present polishing apparatus is the same as the prior art shown in Figs. 21 and 22 . Therefore, in the following description, the same serial numbers are used for the same parts as those of the prior art.

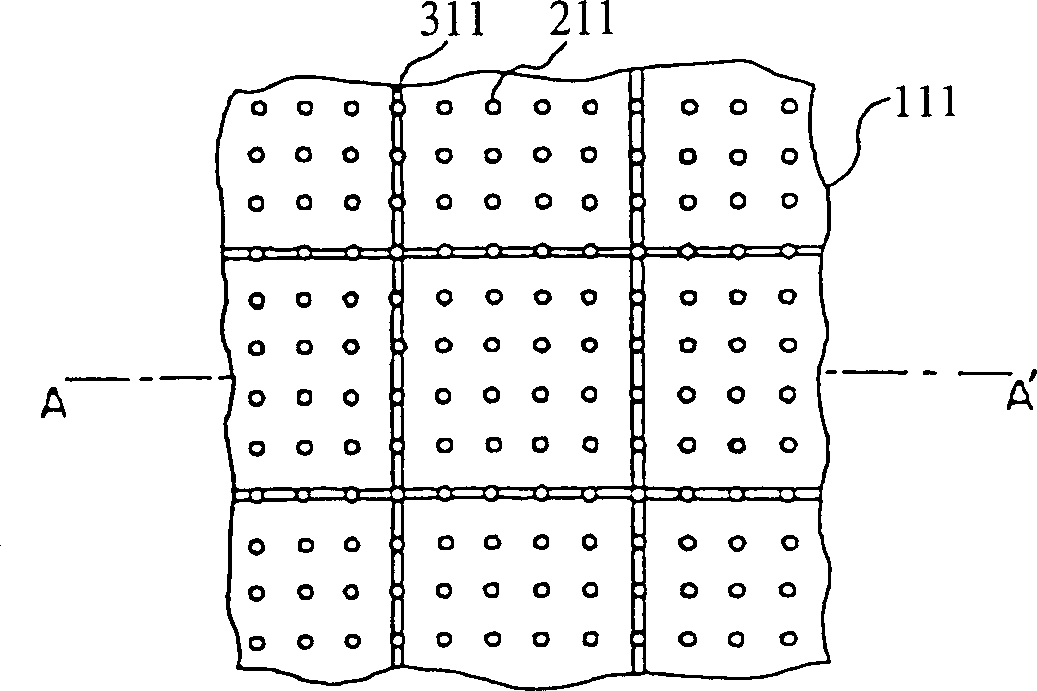

[0052] Such as figure 1 with figure 2 As shown, the polishing pad of the first embodiment of the present invention has shallow groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com