MVR heat concentration circulation evaporation system

An evaporation system and evaporator technology, applied in the field of MVR distillation concentration and evaporation concentration, can solve the problems of high evaporation temperature, low utilization rate of heat energy, and a large amount of cooling water, so as to improve the enthalpy value, improve the service life, and realize the recycling utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

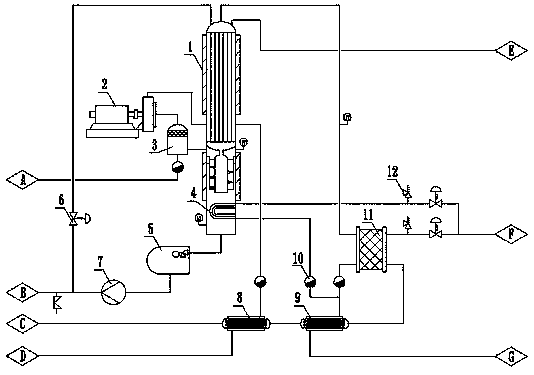

[0028] according to figure 1 As shown, the MVR thermal concentration cycle evaporation system of the present invention mainly consists of an evaporator 1, a centrifugal steam compressor 2, a separation tank 3, a heater 4, a buffer tank 5, a PID regulating valve 6, a centrifugal pump 7, two Secondary steam condensate heat exchanger 8, industrial steam condensate heat exchanger 9, steam trap 10, plate heat exchanger 11, safety valve 12, separation liquid discharge port A, concentrated feed liquid discharge port B, feed liquid inlet C, Secondary steam condensate discharge port D, non-condensable gas discharge port E, industrial steam inlet F, industrial steam condensate discharge port G;

[0029] Among them, the evaporator 1 is a vertical evaporator, the upper tube box of the evaporator is a shell and tube heat exchanger, the upper part of the lower tube box is a spiral separator, and the bottom of the lower tube box is a U-shaped tube heat exchanger; the centrifugal steam compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com