Waste incineration flue gas processing system

A flue gas treatment system and waste incineration technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problem of not meeting the needs of industry development, and achieve the effects of excellent indicators, stable operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

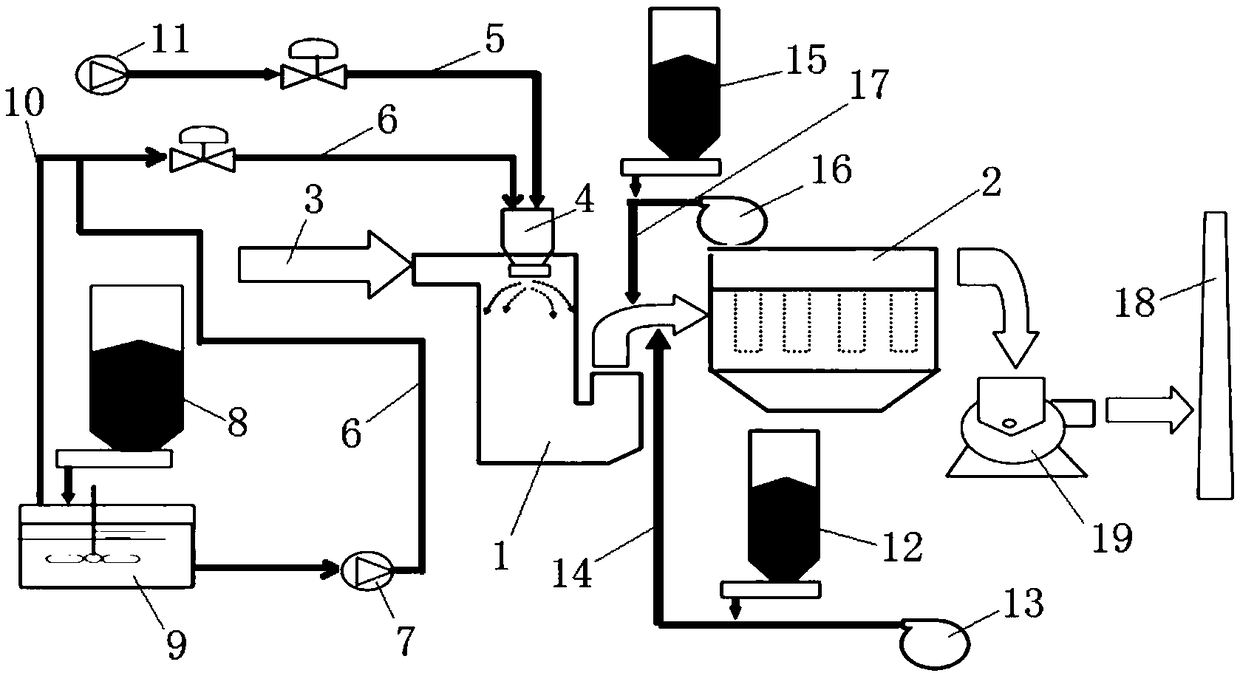

[0025] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

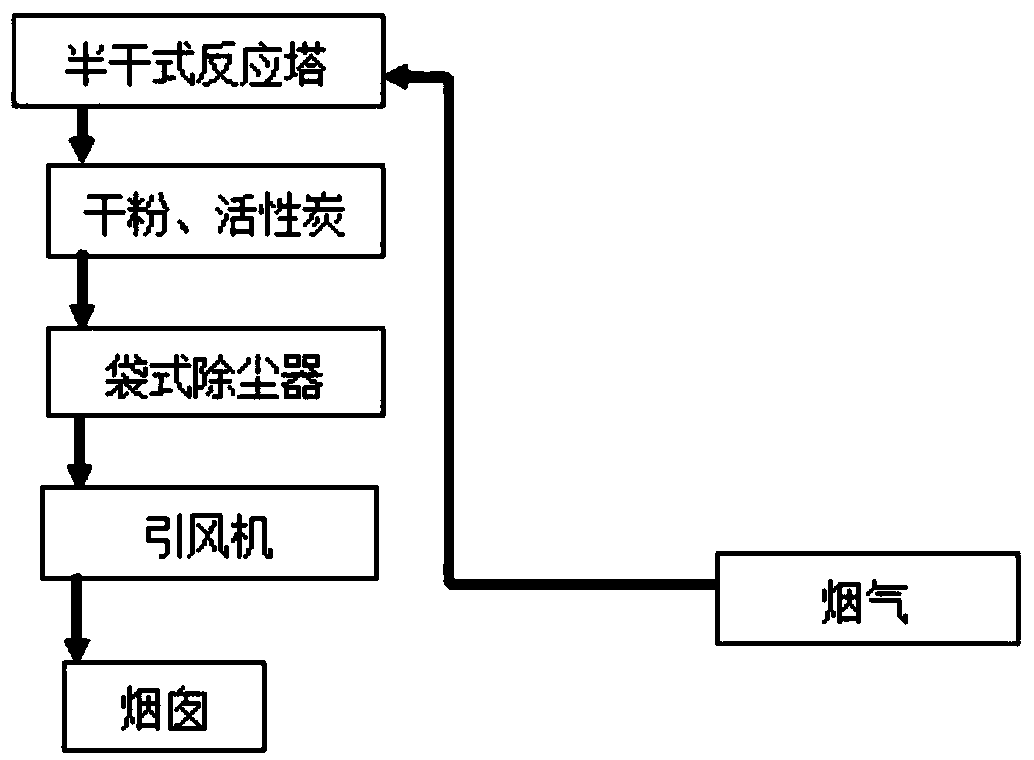

[0026] Such as Figure 1 to Figure 2 As shown, a waste incineration flue gas treatment system includes a reaction tower 1, a dust collector 2 and a flue gas pipeline, the reaction tower is provided with a flue gas 3 inlet, and the top of the reaction tower 1 is provided with a rotary atomizer 4, so The treatment system also includes a water delivery pipeline 5, a lime slurry delivery device and an injection device for spraying adsorbent and slaked lime to the flue gas pipeline between the reaction tower 1 and the dust collector 2, and the water delivery pipeline 5 and the lime slurry delivery devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com