a g-c 3 no 4 Photocatalyst coating and its preparation method and application

A photocatalyst, g-c3n4 technology, applied in the field of photocatalysis, can solve the problems of no activity, photocatalytic performance reduction of photocatalytic coating, etc., and achieve the effect of simple method, good photocatalytic performance and good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] a g-C 3 N 4 The preparation method of photocatalyst coating comprises the steps:

[0019] 1) Take g-C 3 N 4 The photocatalytic material and an appropriate amount of magnesium oxide powder are uniformly ground in a mortar, then the aluminum dihydrogen phosphate solution is added dropwise, the mixture in the mortar is stirred evenly, and then coated on the substrate by brushing or spraying. Gained film drying;

[0020] Preferably, the g-C 3 N 4 The photocatalytic material is obtained by treating the melamine precursor with acetaldehyde, and the specific surface area is 0.5-300m 2 / g of nanoparticles, nanosheets and porous structures.

[0021] By mass ratio, g-C 3 N 4 Photocatalytic material: aluminum dihydrogen phosphate = 1:0.1~1:5.

[0022] By mass ratio, g-C 3 N 4 Photocatalytic material: magnesium oxide = 1:0.5~1:2.

[0023] The substrate is glass, ceramic or metal material.

[0024] 2) The dried film is subjected to acidification treatment and high-temp...

Embodiment 1

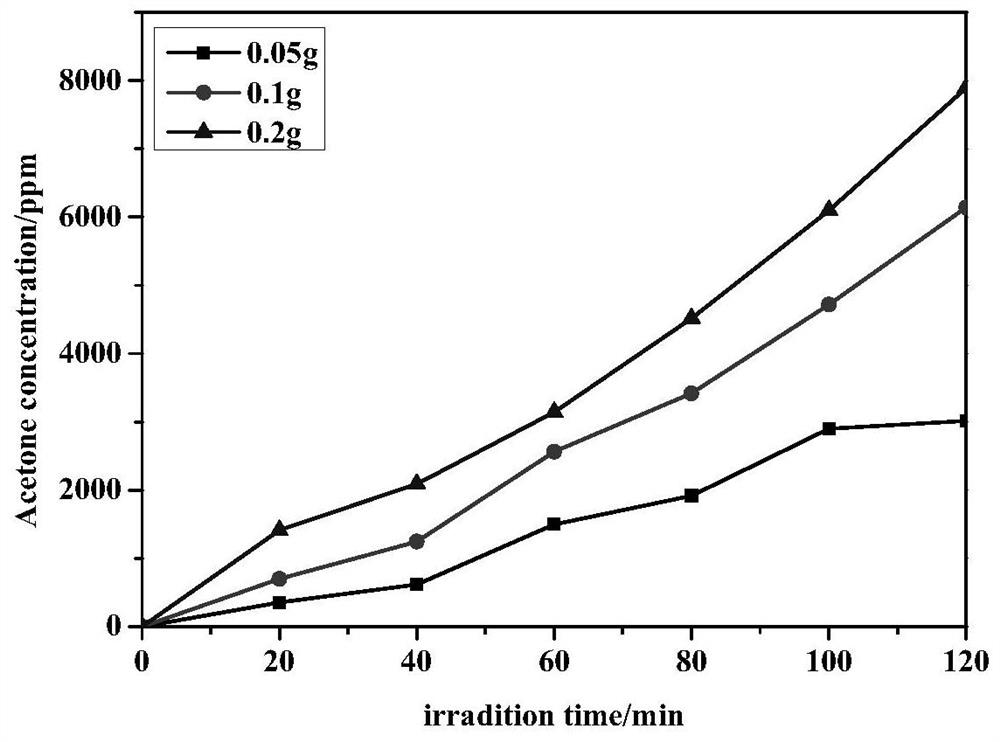

[0028] (1) g-C obtained by different doses of magnesia curing agent 3 N 4 Effect of Photocatalyst Coating on Photocatalytic Performance

[0029] 1. g-C 3 N 4 Preparation of photocatalyst coating

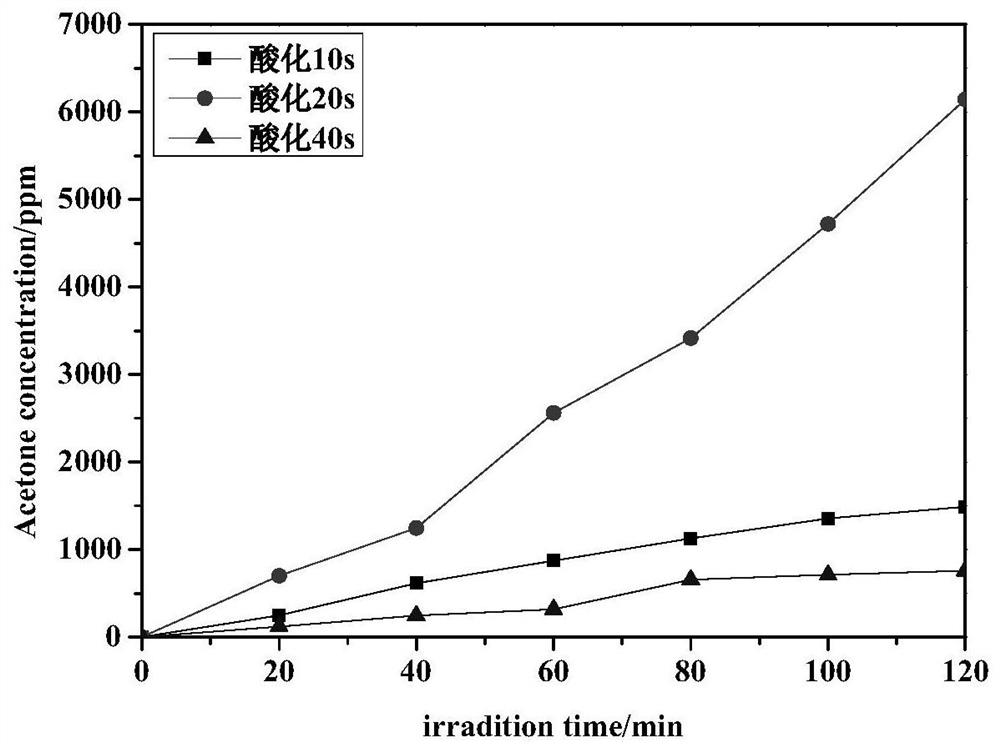

[0030] The specific surface area of 0.1 gram is 162m 2 / g g-C 3 N 4 Pour the photocatalyst and different doses of magnesium oxide powder (0.05g, 0.1g, 0.2g) into the mortar and grind evenly, take 2ml aluminum dihydrogen phosphate solution with a pipette and add it dropwise to the g-C 3 N 4 In the photocatalyst and magnesium oxide, the mixture in the mortar was evenly stirred, and then evenly spread on the glass substrate with a small brush to obtain a film, and the glass substrate loaded with the film was placed in an oven at 100°C for drying. Put the dried film into a beaker filled with dilute sulfuric acid with a concentration of 0.1M, soak for 10 seconds, take it out and put it in an oven, and dry it at 100°C. The dried film was baked at 200°C for 60 minutes to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com