A filament winding auxiliary tooling and winding forming method

An auxiliary tooling and fiber technology, applied in the field of composite material forming, can solve the problem of difficult to eliminate the axial compression stress of the wound core mold, and achieve the effect of avoiding axial stress and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

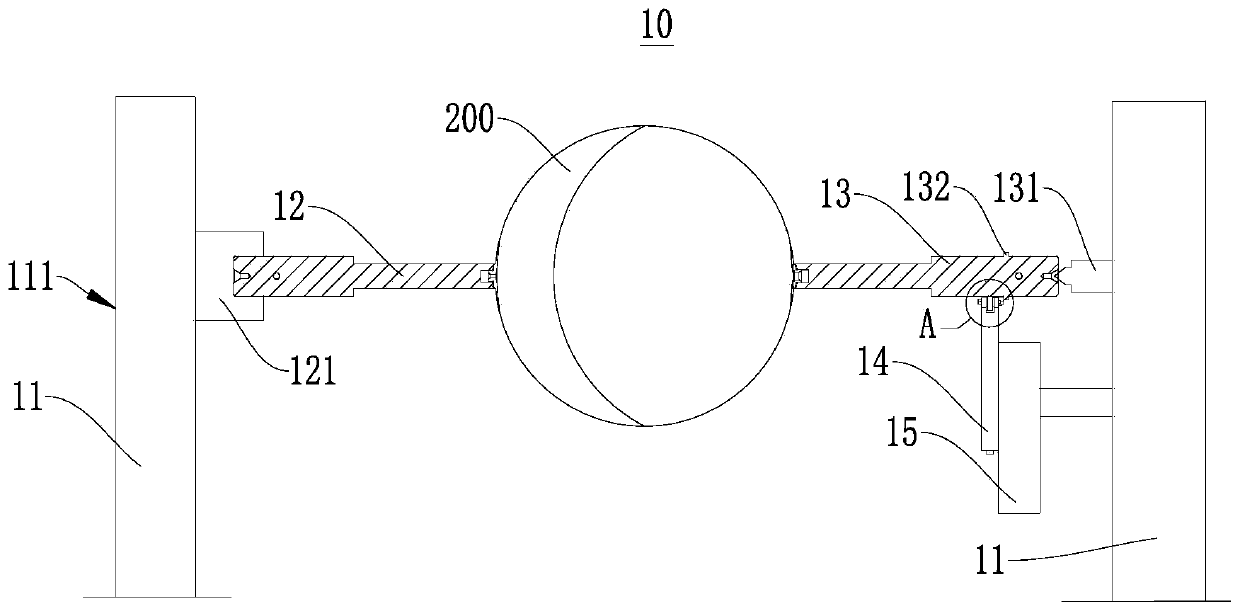

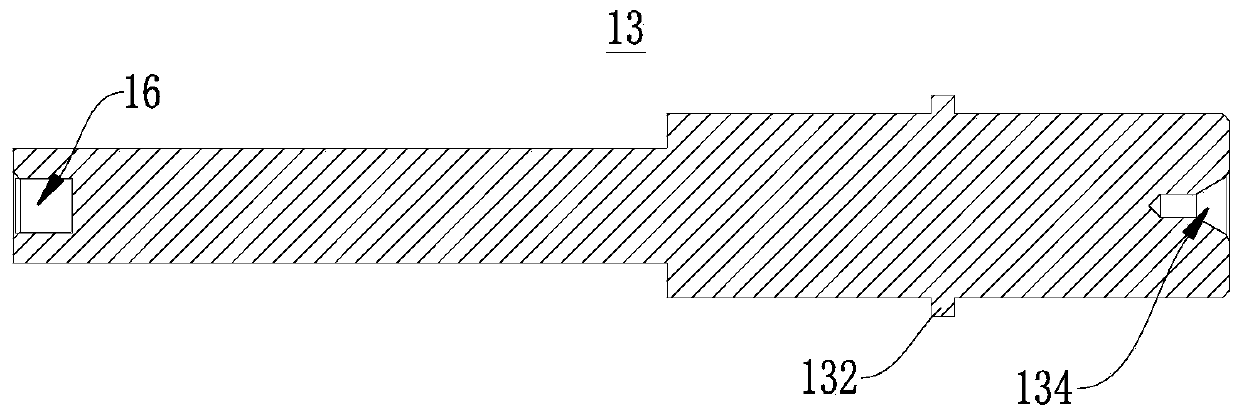

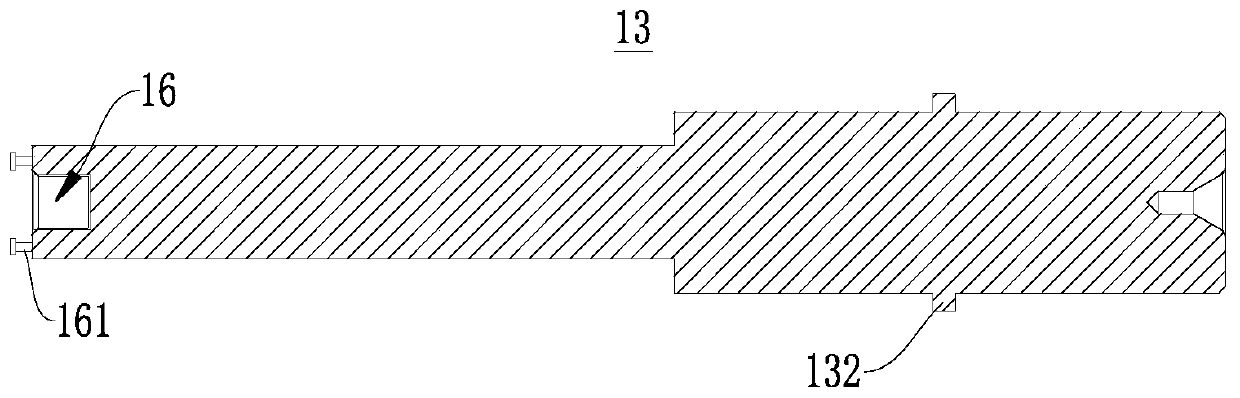

[0045] Please refer to figure 1 , the present embodiment provides a filament winding auxiliary tooling 10, including: an equipment support 11, a first mandrel 12 and a second mandrel 13 that are rotatably mounted on the equipment support 11, and a Limiting support seat 14.

[0046] The equipment support 11 is used for installing the first mandrel 12 and the second mandrel 13 .

[0047] The equipment support 11 may include two pillars 111 for mounting the first mandrel 12 and the second mandrel 13 respectively. A chuck 121 can be set at the position where the first mandrel 12 is installed on the equipment support 11, and the first mandrel 12 is fixed by the chuck 121, so that the first mandrel 12 and the pillar 111 of the equipment support 11 can be rigid Fixed to avoid offset during rotation.

[0048] The first mandrel 12 and the second mandrel 13 are used to rotate and fix the mandrel 200 for fiber winding.

[0049] The first mandrel 12 and the second mandrel 13 are arran...

no. 2 example

[0060] Please refer to Figure 9 , the present invention also provides a winding forming method, which is applied to the auxiliary filament winding tooling of the first embodiment. The mandrel in this embodiment is mainly of large size, with a built-in diaphragm (not penetrated in the middle), and a diameter of φ500mm~ φ1000mm, thin-walled liner with a wall thickness of 0.8mm to 1.5mm, the material of the liner is aluminum alloy, steel or titanium alloy and other metal materials. The auxiliary tooling for filament winding in the present invention can be applied to the mandrel with this characteristic.

[0061] The method includes:

[0062] Step S10: installing the core mold on the core mold installation position.

[0063] In step S10, the specific installation method is: adjust the screw in the waist-shaped hole on the limit support seat to loosen it, place the mandrel between the first mandrel and the second mandrel, and connect it with the first mandrel The shaft and the ...

Embodiment approach

[0072] Specifically, in step S50, the mandrel that has been gelled under preset temperature conditions can be heated to a medium temperature condition, for example, heated to 80°C-100°C for curing, for example, heated in an oven. In this embodiment, two heat-curing implementations are provided: the first one is to transfer the gelled mandrel to an oven for heating and curing, and then process and shape it. The post-curing process does not need to be rotated. The second method is to set up a rotary curing device in the oven, then transfer and install the mandrel that has been gelled on the rotary curing device, and heat and cure it while rotating to ensure the external quality of the product.

[0073] In this embodiment, the resin matrix used for the gel in step S40 and step S50 has the characteristics of gelling under low temperature conditions (35°C) and curing under medium and low temperature conditions (below 100°C); such as an aluminum alloy core with a diameter of φ500mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com