Rubbish management system based on wireless sensor technology

A wireless sensor and management system technology, applied in the field of garbage management, can solve the problems of decreased detection accuracy, inconsistent quantity of garbage, and position offset, etc., and achieve the effects of fast response, reduced time inconsistency, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

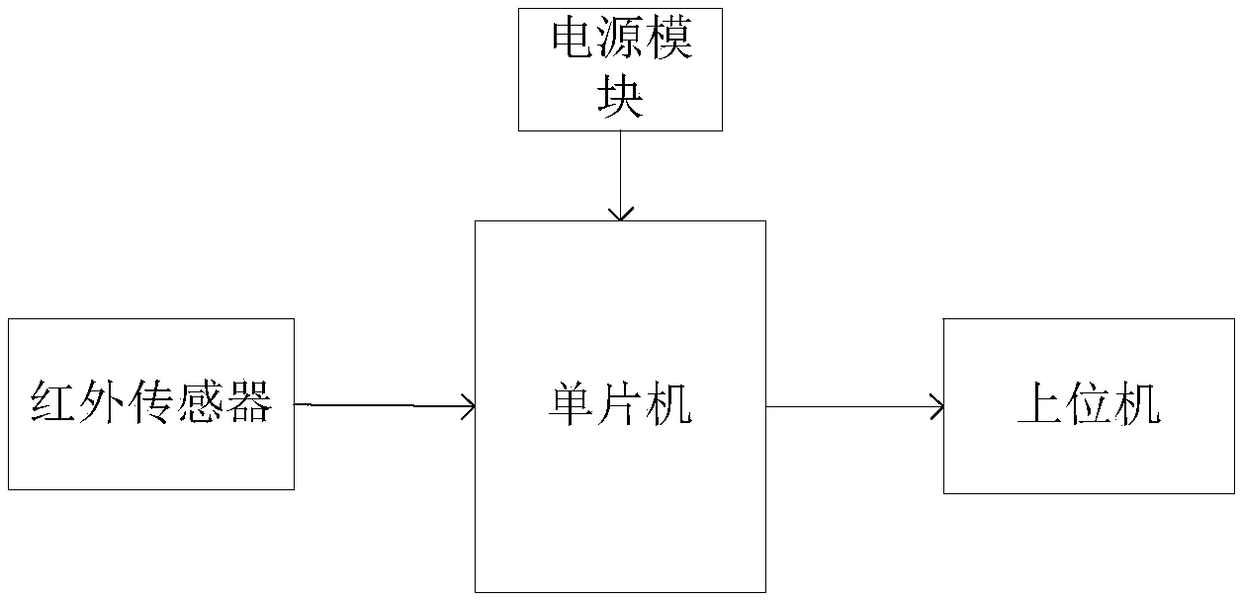

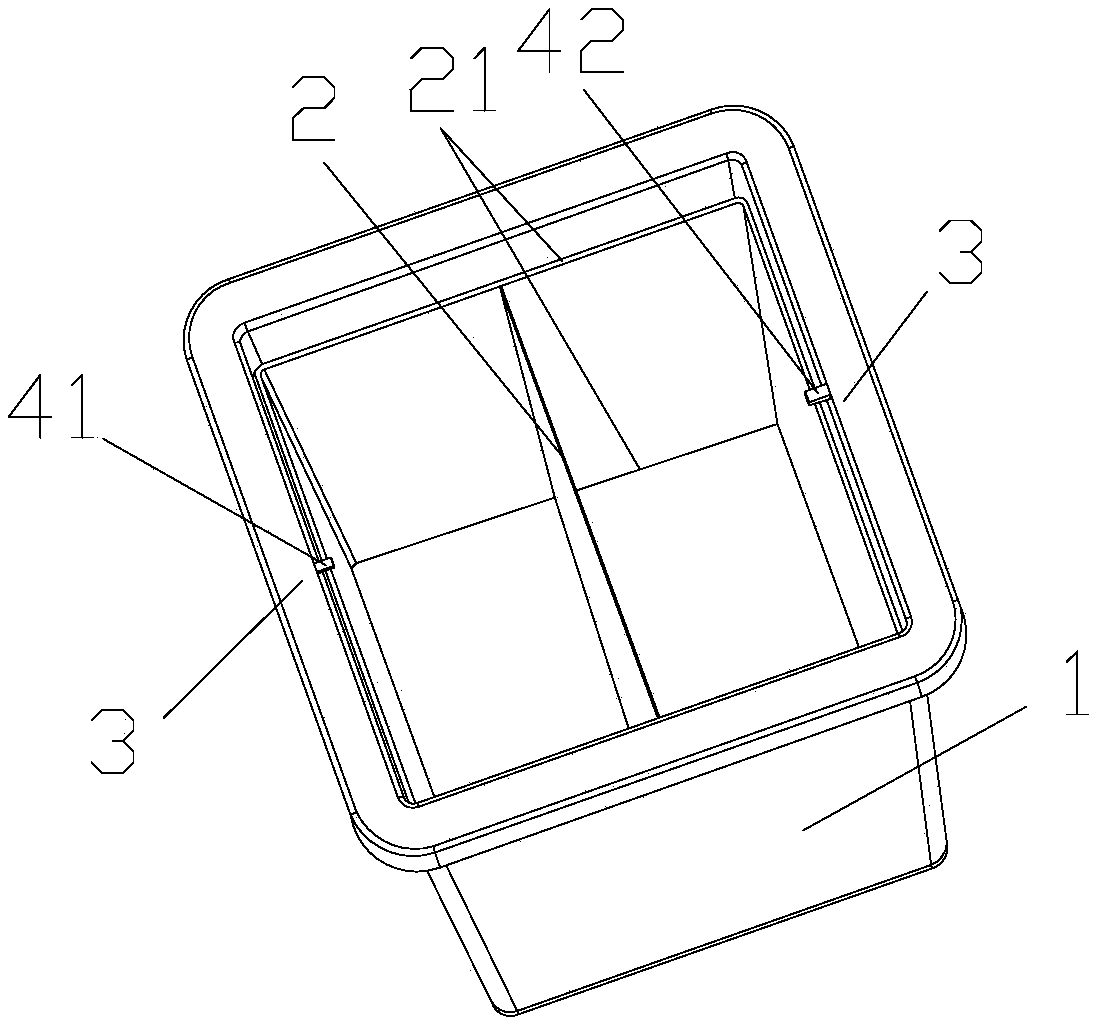

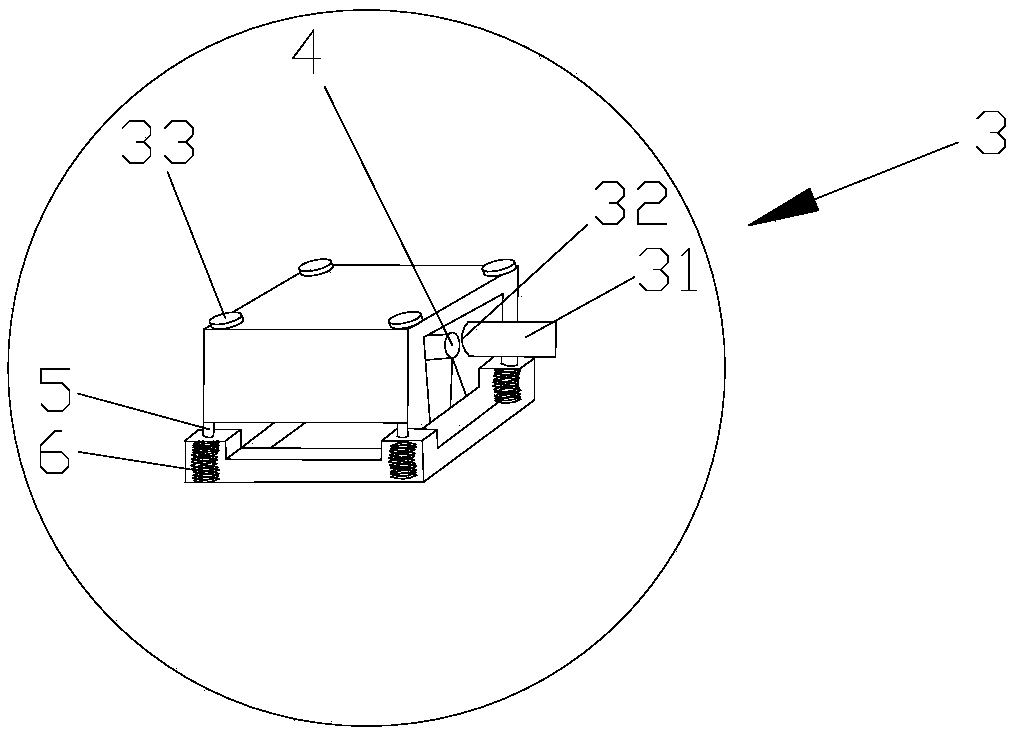

[0025] Such as Figure 1 to Figure 5 As shown, based on the wireless sensor technology garbage management system, the management system includes a barrel body 1, and the barrel body 1 is provided with a partition 2 to divide the barrel body 1 into two areas of recyclable garbage and non-recyclable garbage. The bottom of the opening of the barrel body 1 and the bottom of the barrel body 1 are provided with chute 21, and the chute 21 located on the front and rear sides of the barrel body 1 is slidably connected with the partition plate 2, and the middle position of the left and right sides of the opening of the barrel body 1 There is a groove, the shape and size of the groove match the shape and size of the shock absorber 3, and the shock absorber 3 is detachably installed in the groove, and the shock absorber 3 includes an infrared sensor embedded in it. 4, single-chip microcomputer, power supply module, described infrared sensor 4 comprises infrared transmitting terminal 41 an...

Embodiment 2

[0029] Such as Figure 1 to Figure 5As shown, the difference between this embodiment and Embodiment 1 is that the barrel body 1, the infrared sensor 4, the single-chip microcomputer, and the power module are electrically connected through wiring. Threads are provided at the junction of the damping device 3 and the screw mandrel 5, and the screw mandrel 5 is adjusted in height by rotation. The four corners of the bottom of the damping device 3 are all provided with screw rods 5, and by adjusting each screw rod 5 to adjust the height and inclination of the damping device 3 in all directions, high-precision calibration is achieved. The rubber damping pad 33 is made of NR material. NR material has excellent elasticity, good fatigue resistance, low heat generation, small creep, good adhesion with metal parts, cold resistance, electrical insulation and processing performance. The barrel body 1 is provided with a barrel cover 11 matching the opening area of the barrel body 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com