Elevator brake with emergency brake system and working method for elevator brake

An elevator brake and emergency braking technology, which is applied in the direction of brake types, elevators, hoisting devices, etc., can solve problems such as insufficient braking force, failure of braking force, and inability to close and close the brakes, so as to reduce noise and increase braking force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

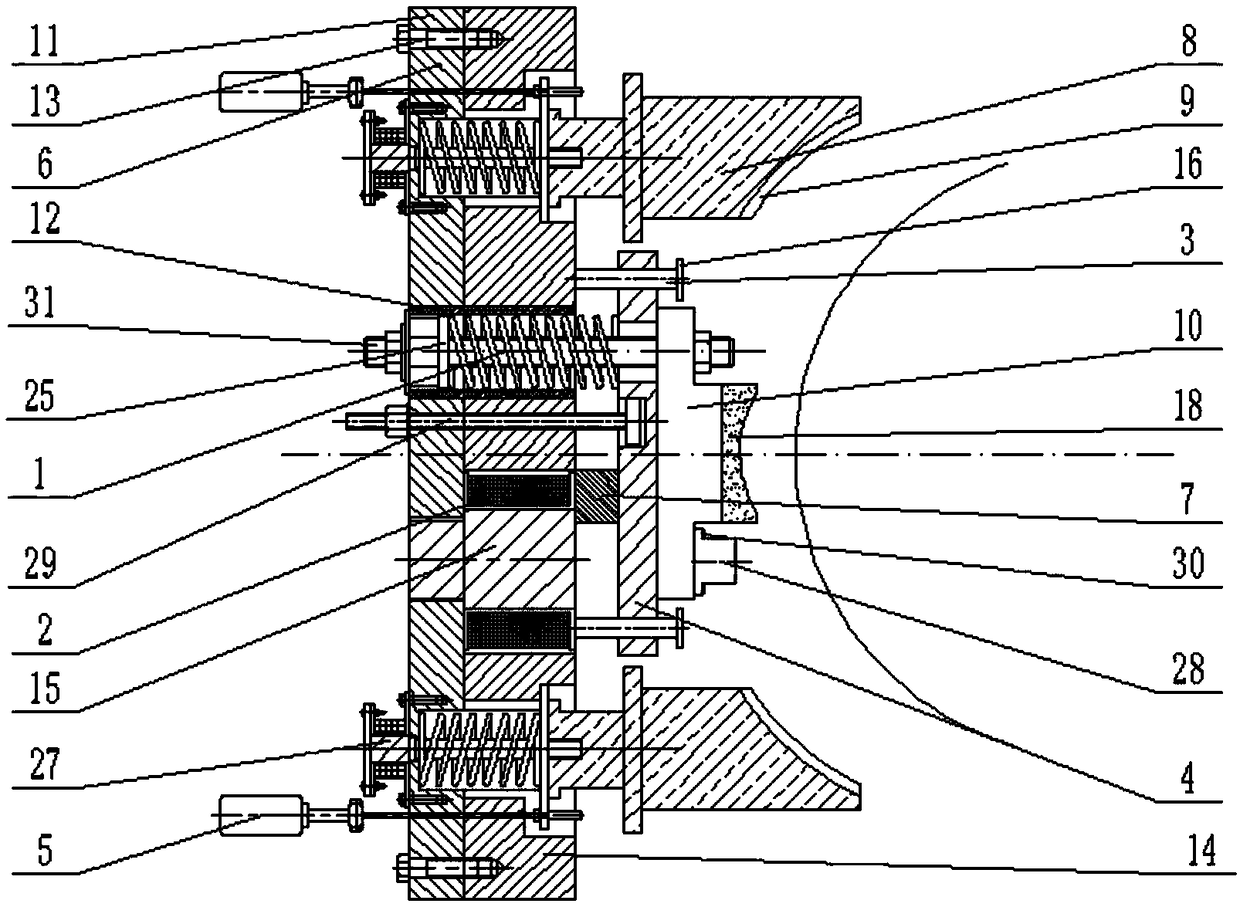

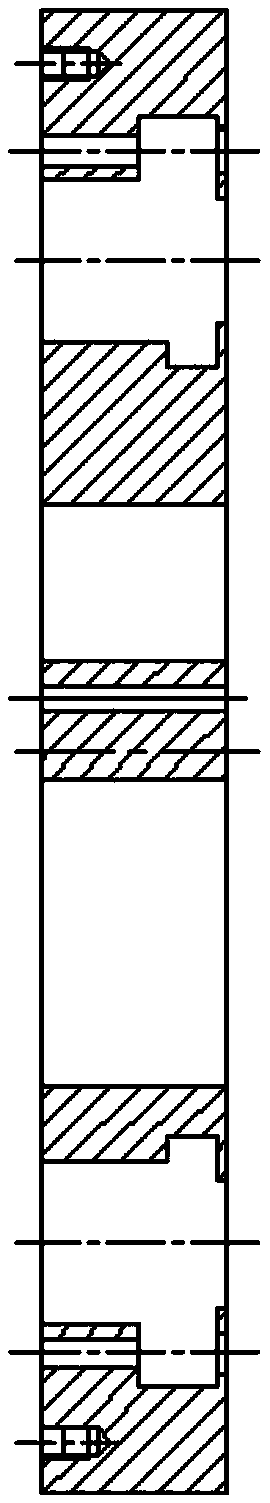

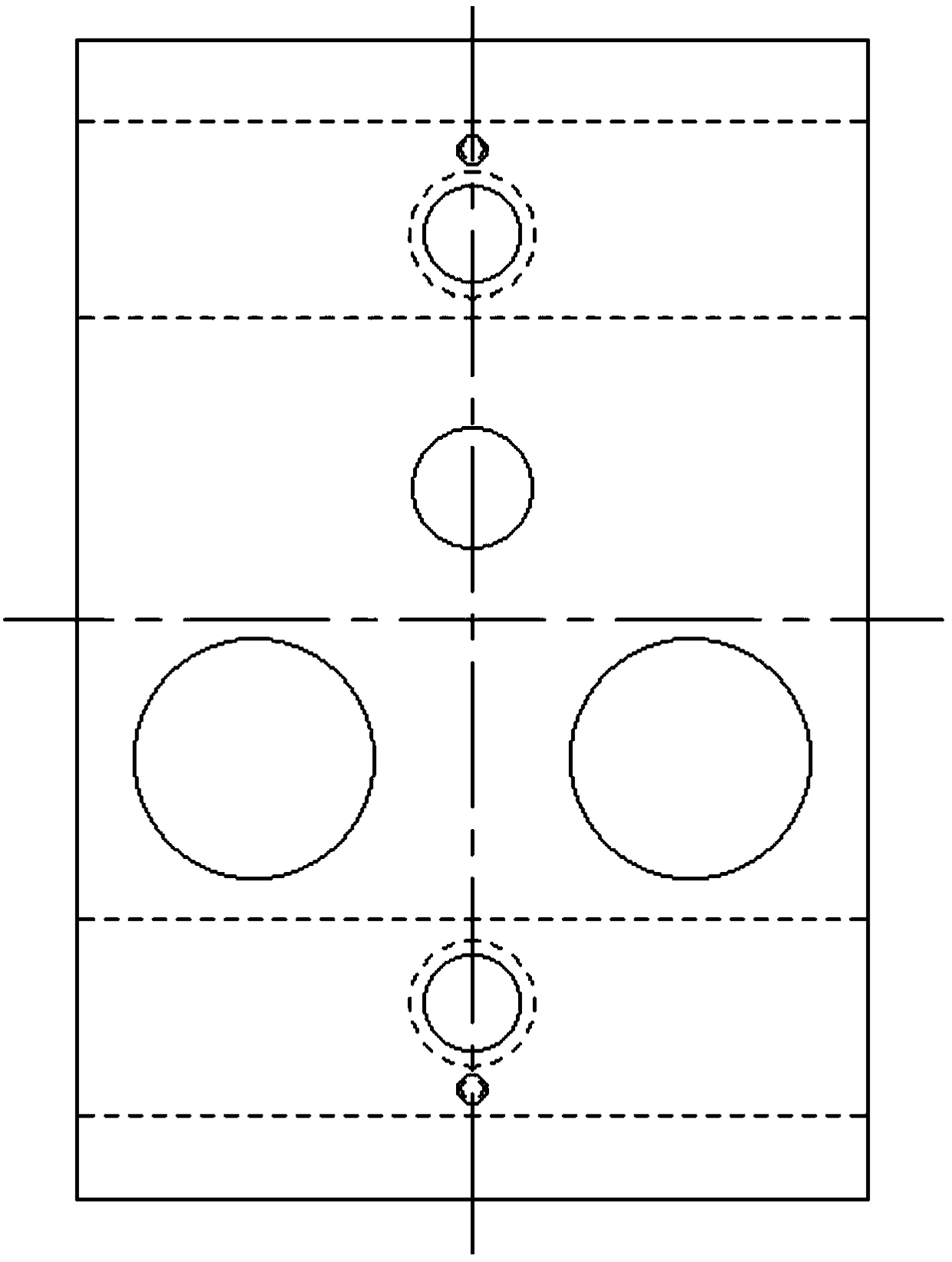

[0037] The present invention will be further described below in conjunction with the drawings.

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the elevator brake with emergency braking system includes brake spring 1, coil winding 2, guide post 3, armature 4, emergency brake assembly 5, manual brake release lever 29, preload adjustment lever 31, and return The assembly 27, the combined support body 6, the tongue plate 10, and the friction brake shoe 18 fixed on the tongue plate 10; the combined support body 6 includes a housing 11, a spring sleeve 12 and an iron core plate 14; the housing 11 is provided with a sleeve Mounting hole one, brake release lever mounting hole one, two brake assembly mounting holes one, two iron core post mounting holes one and two rotating shaft mounting holes one; sleeve mounting hole one, brake release lever mounting hole one, The centers of the two brake component mounting holes one and the two rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com