A kind of preparation method of ethyl ether group-α, ω-double long-chain alkyl dimethyl ammonium chloride surfactant

A long-chain alkyl dimethyl ammonium chloride and surfactant technology, which is applied in the preparation of amino hydroxyl compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low final yield, long reaction time, and limitations Problems such as the popularization and application of gemini surfactants to achieve the effect of increasing productivity and improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

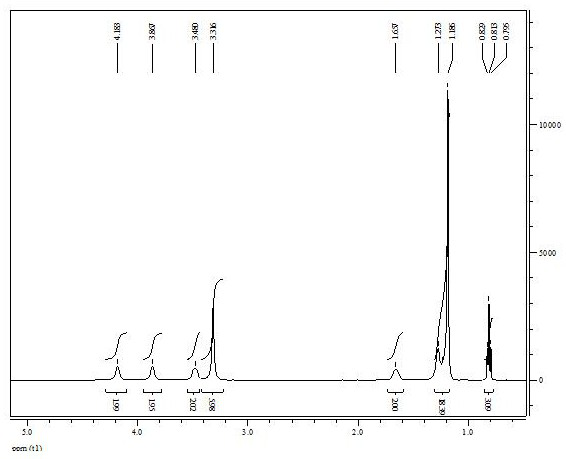

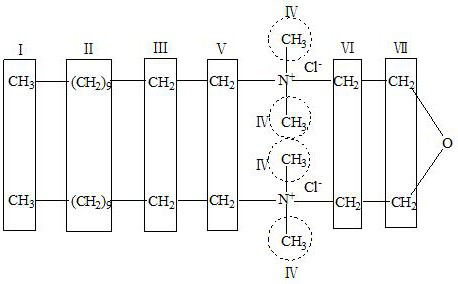

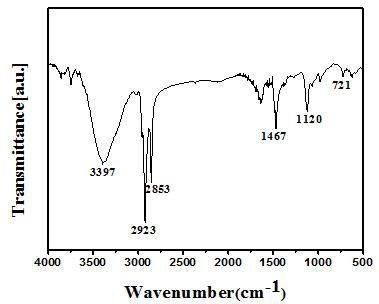

Embodiment 1

[0037] Weigh 31.4g (0.2mol) of octyldimethyl tertiary amine, 38.5g of isopropanol, and 0.4g of solid sodium hydroxide into a four-neck flask, start stirring and heating. Weigh 11.4 g (0.08 mol) of dichloroethyl ether and add it to the dropping funnel, and start dropping when the temperature reaches 50° C., and control the dropping time for 10 minutes. After the dichloroethyl ether is added dropwise, the reaction temperature is controlled at 80° C., and the reaction time is 6 hours, and the product etheryl-α,ω-bisoctyldimethylammonium chloride can be obtained. After chemical analysis (water / chloroform two-phase titration, bromophenol blue as indicator, titration with sodium tetraphenylborate standard solution) and calculation, the reaction yield is 50.47wt%.

[0038] Rotate the liquid product obtained in the above steps to remove the solvent, wash 3 times with diethyl ether to remove the excess reactant dichloroethyl ether, then wash 3 times with acetone to remove the excess re...

Embodiment 2

[0040] Weigh 37g (0.2mol) of decyldimethyl tertiary amine, 50g of isopropanol, and 0.6g of solid sodium carbonate into a four-necked bottle, start stirring and heating. Weigh 12.9 g (0.09 mol) of dichloroethyl ether and add it to the dropping funnel, start dropping when the temperature reaches 55°C, and control the dropping time for 15 minutes. After the dichloroethyl ether is added dropwise, the reaction temperature is controlled at 83° C., and the reaction time is 8 hours, and the product etheryl-α,ω-didecyldimethylammonium chloride can be obtained. After chemical analysis (water / chloroform two-phase titration, bromophenol blue as indicator, titrated with sodium tetraphenylborate standard solution) and calculated, the reaction yield was 53.21wt%.

[0041] Rotate the liquid product obtained in the above steps to remove the solvent, wash 4 times with diethyl ether to remove the excess reactant dichloroethyl ether, then wash 4 times with acetone to remove the excess reactant te...

Embodiment 3

[0043] Weigh 42.6g (0.2mol) of dodecyldimethyl tertiary amine, 58g of deionized water, and 0.8g of solid sodium carbonate into a four-neck flask, start stirring and heating. Weigh 15.1 g (0.105 mol) of dichloroethyl ether and add it to the dropping funnel, start dropping when the temperature reaches 60°C, and control the dropping time for 20 minutes. After the dichloroethyl ether is added dropwise, the reaction temperature is controlled at 95° C., and the reaction time is 8 hours, and the product etheryl-α,ω-didodecyldimethylammonium chloride can be obtained. After chemical analysis (water / chloroform two-phase titration, bromophenol blue as indicator, titrated with sodium tetraphenylborate standard solution) and calculated, the reaction yield was 80.02wt%.

[0044] Rotate the liquid product obtained in the above steps to remove the solvent, wash 5 times with diethyl ether to remove the excess reactant dichloroethyl ether, then wash 5 times with acetone to remove the excess rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com