Liquid crystal material, and preparation method and application thereof

A liquid crystal material and selected technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of restricting the application of organic light-emitting materials, weakening light emission, restricting the application of light-emitting liquid crystal materials, etc., achieving mild conditions and easy operation. , good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

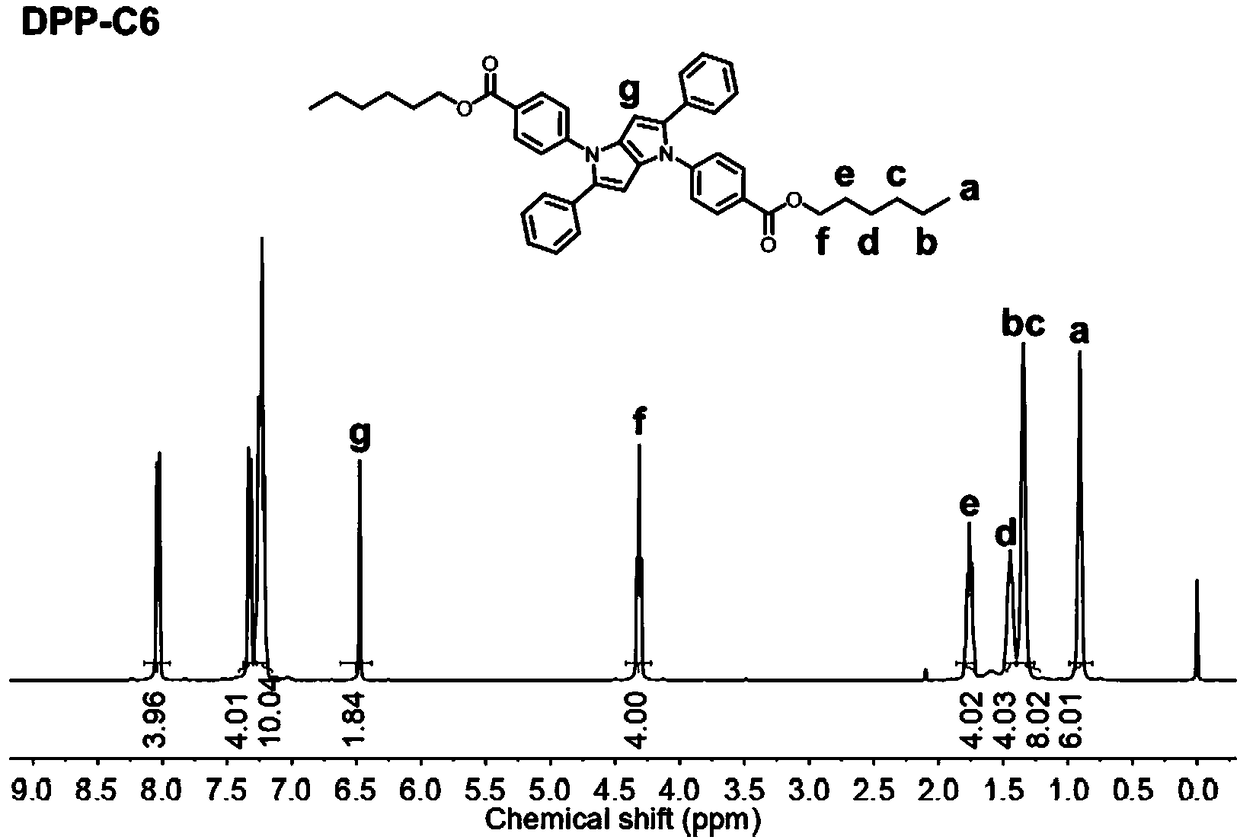

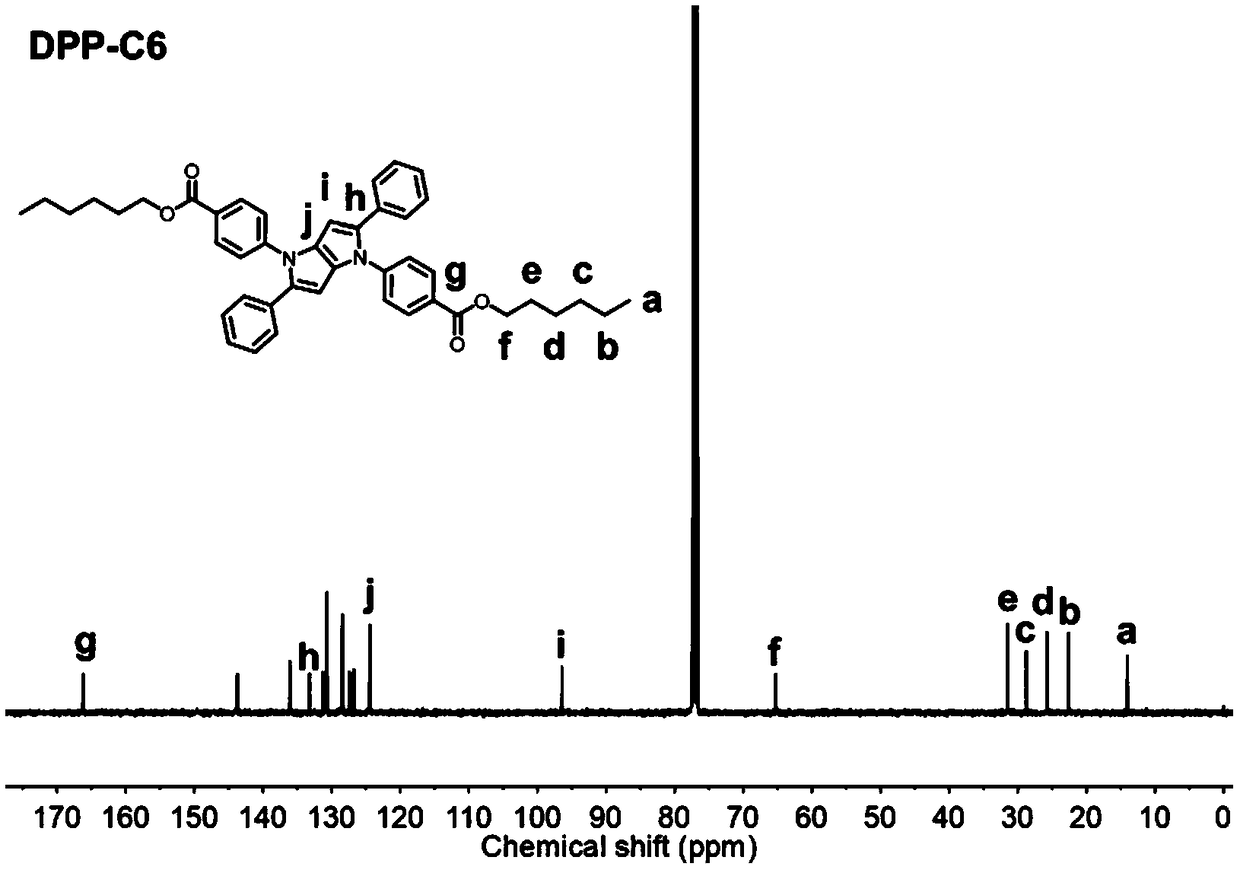

[0056] This embodiment provides a liquid crystal material, the structural formula of the liquid crystal material is as follows:

[0057] It is called DPP-C6 for short.

[0058] The synthetic route of described DPP-C6 is as follows:

[0059]

[0060] Described preparation method comprises the steps:

[0061] Add 50 mL of acetic acid, 5.0 g (0.023 mol) of n-hexyl aminobenzoate, 2.4 g (0.023 mol) of benzaldehyde, and 0.40 g (0.0023 mol) of p-toluenesulfonic acid into the reaction flask in sequence. After the above mixed solution was heated to 90° C. and stirred for 30 min, 0.97 g (0.0113 mol) of 2,3-butanedione was added dropwise. After the dropwise addition was completed, the stirring reaction was continued for 3 h. After the reaction, the reaction solution was cooled to room temperature and subjected to suction filtration, and the filter cake was repeatedly washed with acetic acid. The obtained crude product filter cake was recrystallized with a mixed solution of dichlo...

Embodiment 2

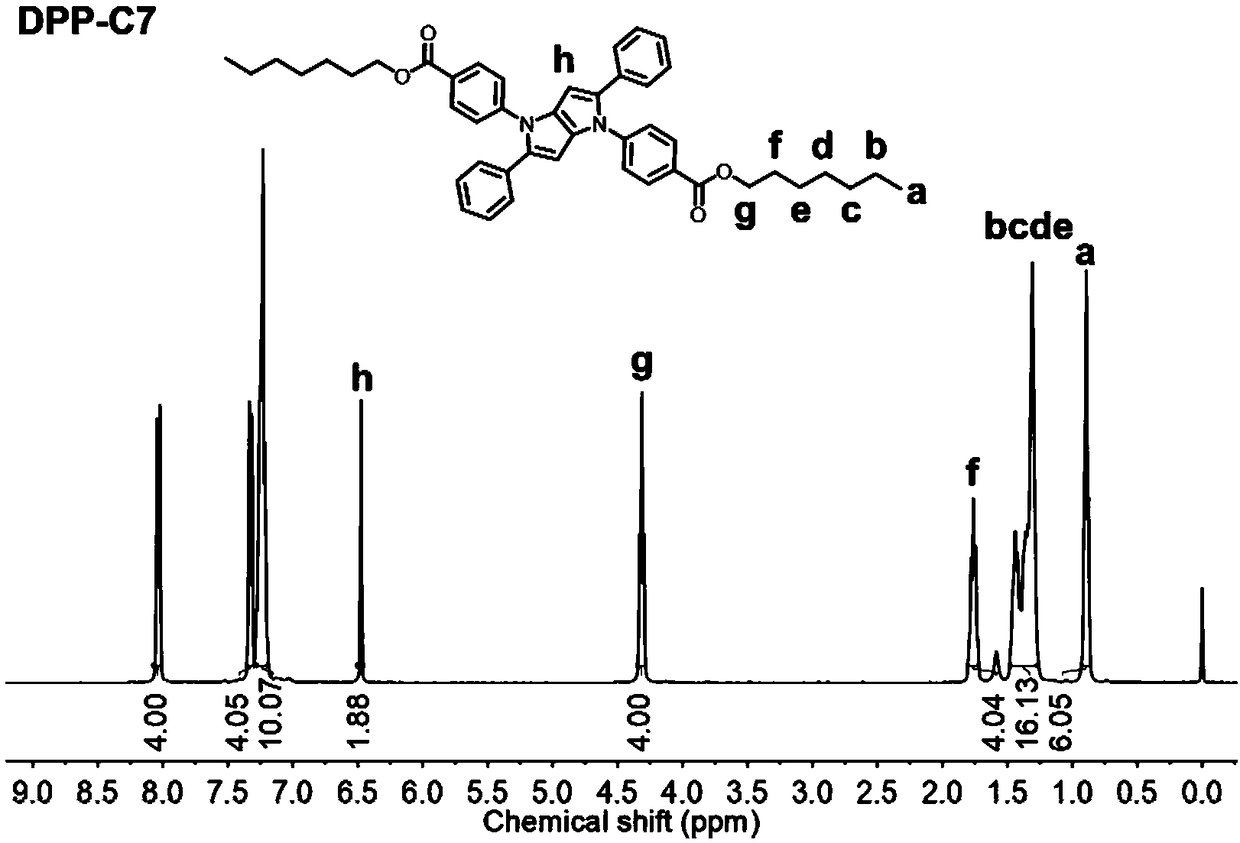

[0067] This embodiment provides a liquid crystal material, the structural formula of the liquid crystal material is as follows:

[0068] It is called DPP-C7 for short.

[0069] The synthetic route of the DPP-C7 is as follows:

[0070]

[0071] Described preparation method comprises the steps:

[0072] Add 50 mL of acetic acid, 5.4 g (0.023 mol) of n-heptyl 4-aminobenzoate, 2.4 g (0.023 mol) of benzaldehyde, and 0.40 g (0.0023 mol) of p-toluenesulfonic acid into the reaction flask. After the above mixed solution was heated to 90° C. and stirred for 30 min, 0.97 g (0.0113 mol) of 2,3-butanedione was added dropwise. After the dropwise addition was completed, the stirring reaction was continued for 3 h. After the reaction, the reaction solution was cooled to room temperature and subjected to suction filtration, and the filter cake was repeatedly washed with acetic acid. The obtained crude product filter cake was recrystallized with a mixed solution of dichloromethane and e...

Embodiment 3

[0078] This embodiment provides a liquid crystal material, the structural formula of the liquid crystal material is as follows:

[0079] It is called DPP-C8 for short.

[0080] The synthetic route of described DPP-C8 is as follows:

[0081]

[0082] Described preparation method comprises the steps:

[0083] Add 50 mL of acetic acid, 5.7 g (0.023 mol) of n-octyl 4-aminobenzoate, 2.4 g (0.023 mol) of benzaldehyde, and 0.40 g (0.0023 mol) of p-toluenesulfonic acid in the reaction flask. After the above mixed solution was heated to 90° C. and stirred for 30 min, 0.97 g (0.0113 mol) of 2,3-butanedione was added dropwise. After the dropwise addition was completed, the stirring reaction was continued for 3 h. After the reaction, the reaction solution was cooled to room temperature and subjected to suction filtration, and the filter cake was repeatedly washed with acetic acid. The obtained crude product filter cake was recrystallized with a mixed solution of dichloromethane an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com