Method for purifying and preparing antibacterial peptide

A technology of antimicrobial peptides and antimicrobial peptide solutions, applied in the field of purification, to achieve the effects of reducing the number of purification times and steps, shortening the purification process route, and improving purification efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for purifying and preparing antimicrobial peptides, comprising:

[0038] (1) Sample treatment: The antimicrobial peptide crude peptide with a chromatographic purity of more than 50% was obtained by solid-phase synthesis, dissolved in purified water at a concentration of 50g / L, stirred, and filtered with a 0.45um water filter membrane after complete dissolution. Remove the insoluble matter to obtain the filtrate, which is the crude antimicrobial peptide after drying.

[0039] (2) Initial purification: Add 3.2 L of purified water to 160 g of antimicrobial peptide crude product to prepare a 50 mg / ml antimicrobial peptide crude product solution, and then filter with a microporous membrane to obtain a crude antimicrobial peptide solution for later use.

[0040] Put the antimicrobial peptide crude product solution into an RC semipermeable membrane with a molecular weight cut-off of 500 Daltons, about 60% of the total capacity volume, into 32L acetate buffer solution,...

Embodiment 2

[0048] This example is a comparative example of Example 1. In this example, the purification method and conditions in the comparative document CN201511014180.X are used to treat the antimicrobial peptide. The treatment process and results are as follows:

[0049] Step 1. Take 5 g of antibacterial peptide crude peptide, add 50 ml of 1% acetic acid solution, and prepare 10% antibacterial peptide crude peptide solution.

[0050] Step 2, the acetic acid solution of antimicrobial peptide is loaded into is that 500 Dalton RC semi-permeable membranes are packed in molecular weight cut-off, and loading is 70% of semi-permeable membrane loading volume, is placed in 2L acetate buffer (pH3.5 ) buffer solution, stirred and diafiltered at 20-30°C until the buffer solution pH=2.0-3.0.

[0051] Step 3. Transfer the semipermeable membrane of the acetic acid solution containing the antimicrobial peptide to 3L of purified water, stir and diafilter at 20-30° C. until the pH of the solution in the ...

Embodiment 3

[0064] The present embodiment is the comparative example of embodiment 1, only adopts the reversed-phase chromatography in embodiment 1 to purify in the present embodiment, concrete process and experimental result are as follows:

[0065] (1) Sample treatment: Dissolve the antimicrobial peptide in purified water at a concentration of 50mg / mL, stir, and filter it with a 0.45um water filter membrane after completely dissolving to remove insoluble matter to obtain the filtrate, which is the crude antimicrobial peptide after drying .

[0066] (2) Initial purification: add purified water to 2 g of antimicrobial peptide crude product to prepare a 35% antimicrobial peptide crude product solution, then filter with a microporous membrane to obtain the antimicrobial peptide crude product solution for later use.

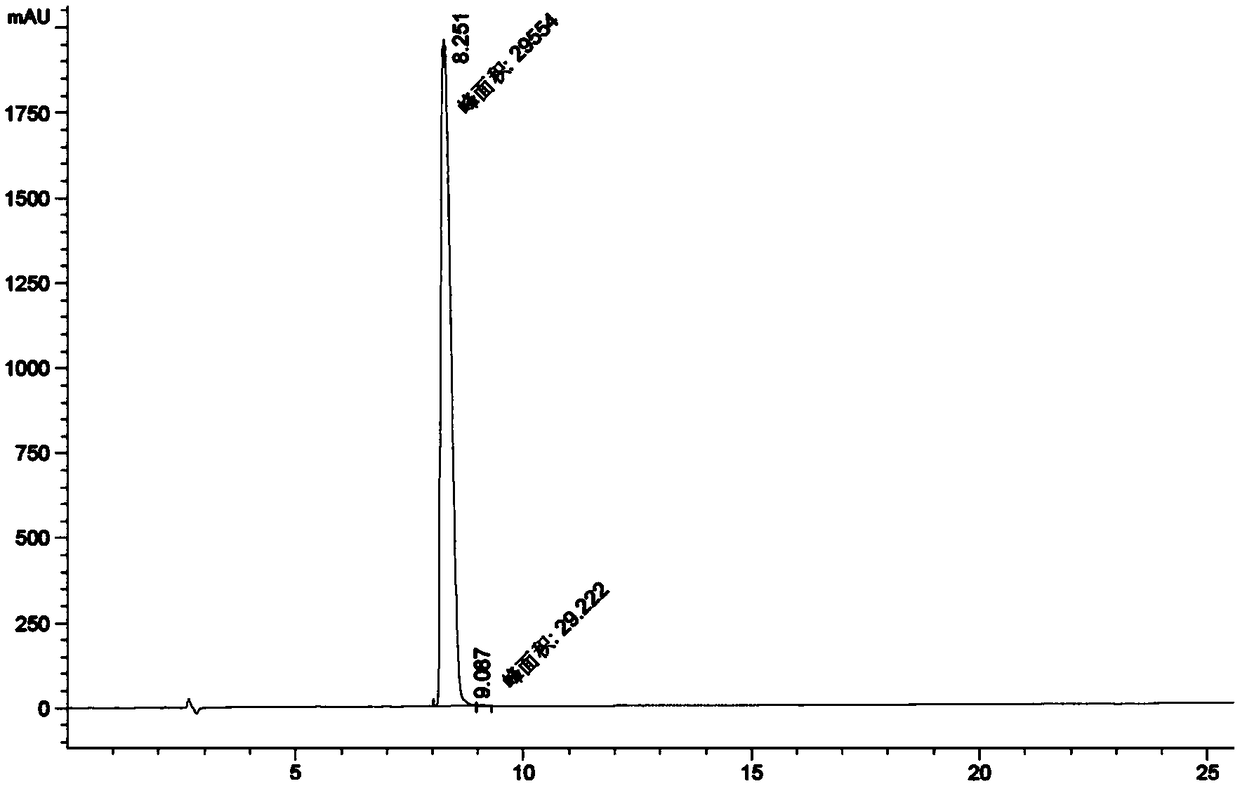

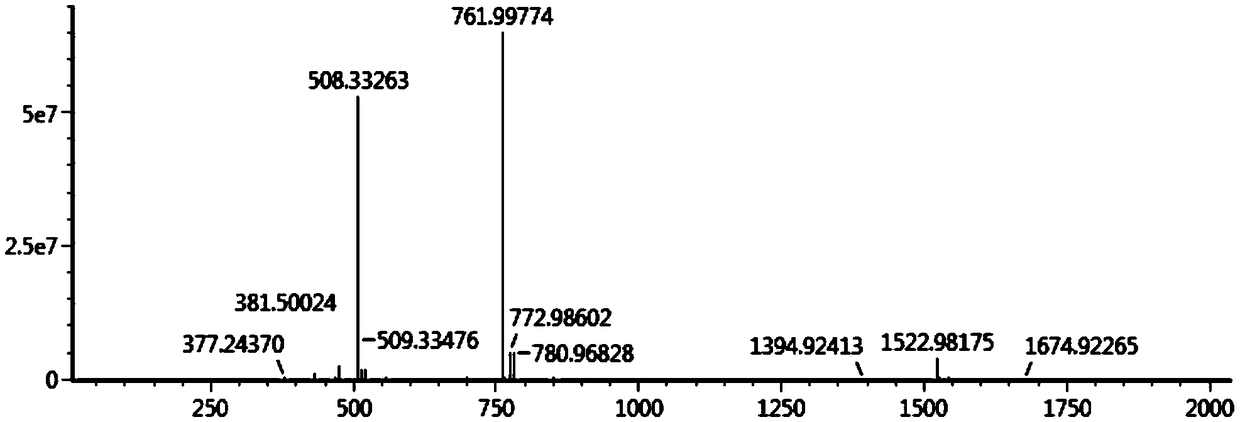

[0067] (3) pure

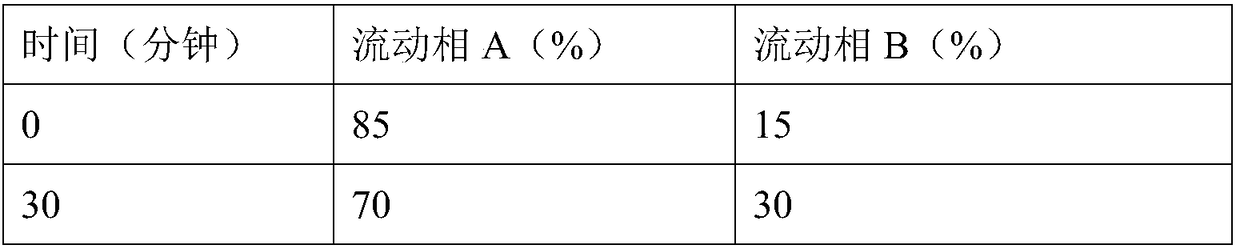

[0068] Reversed-phase chromatographic conditions: a high-performance liquid chromatography preparative column with octadecylsilane bonded silica gel as the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com