Rubber hose assembly for fire extinguisher and production method thereof

A technology for rubber hoses and fire guns, applied in the directions of hoses, hose connection devices, pipes, etc., can solve the problems of poor flame retardant performance, sacrificing high temperature resistance, etc., to ensure corrosion resistance, tensile and blasting performance. Excellent, avoid burning or high temperature cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The technical solutions of the present invention will be further described below in conjunction with specific examples.

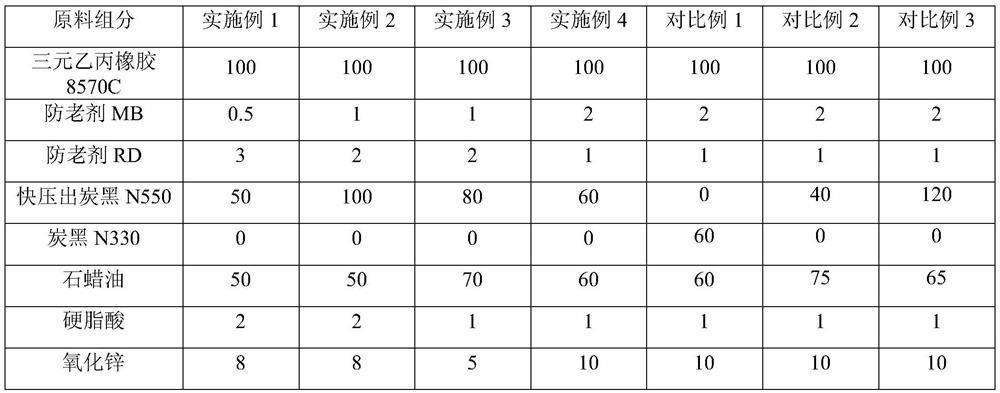

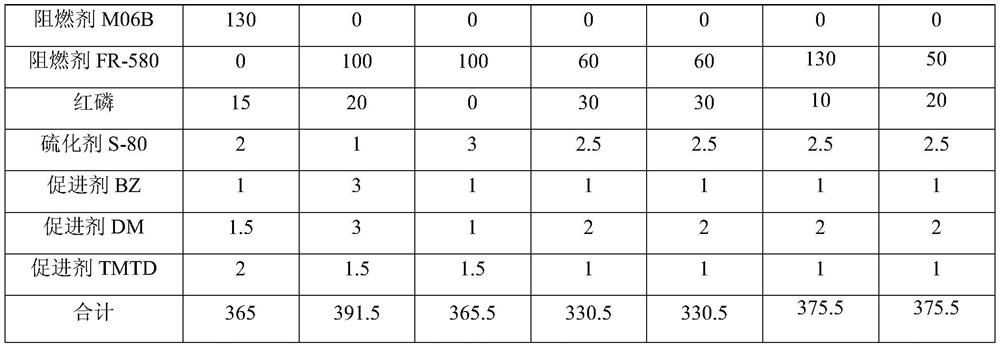

[0029] Raw material components and proportioning ratio (unit: g) of table 1 ethylene-propylene rubber composition

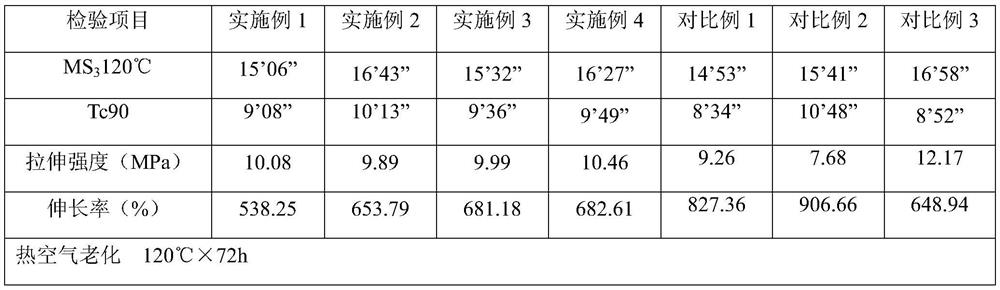

[0030]

[0031]

[0032] A rubber hose assembly for a fire extinguisher, comprising a rubber hose and metal joints at both ends of the rubber hose. For the rubber layer, the wall thickness of the inner rubber layer is 1.9mm, the wall thickness of the outer rubber layer is 1.3mm, and the thickness of the braid layer between the inner and outer rubber layers is 0.9mm; the inner diameter of the rubber hose is 10±0.3mm. The preparation method is as follows:

[0033] Step (1), weigh the raw materials of the rubber composition according to Table 1, add to the internal mixer and mix for about 100 seconds to form an ethylene-propylene rubber composition compound; 3 knives, and then send the mixed rubber to the tablet press through the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com