High-efficiency preparation method of heparinase I from Flavobacterium heparinum

A technology of Flavobacterium heparin and heparinase, applied in the field of producing crude enzymes using osmotic stress, can solve problems such as complex chromatography processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

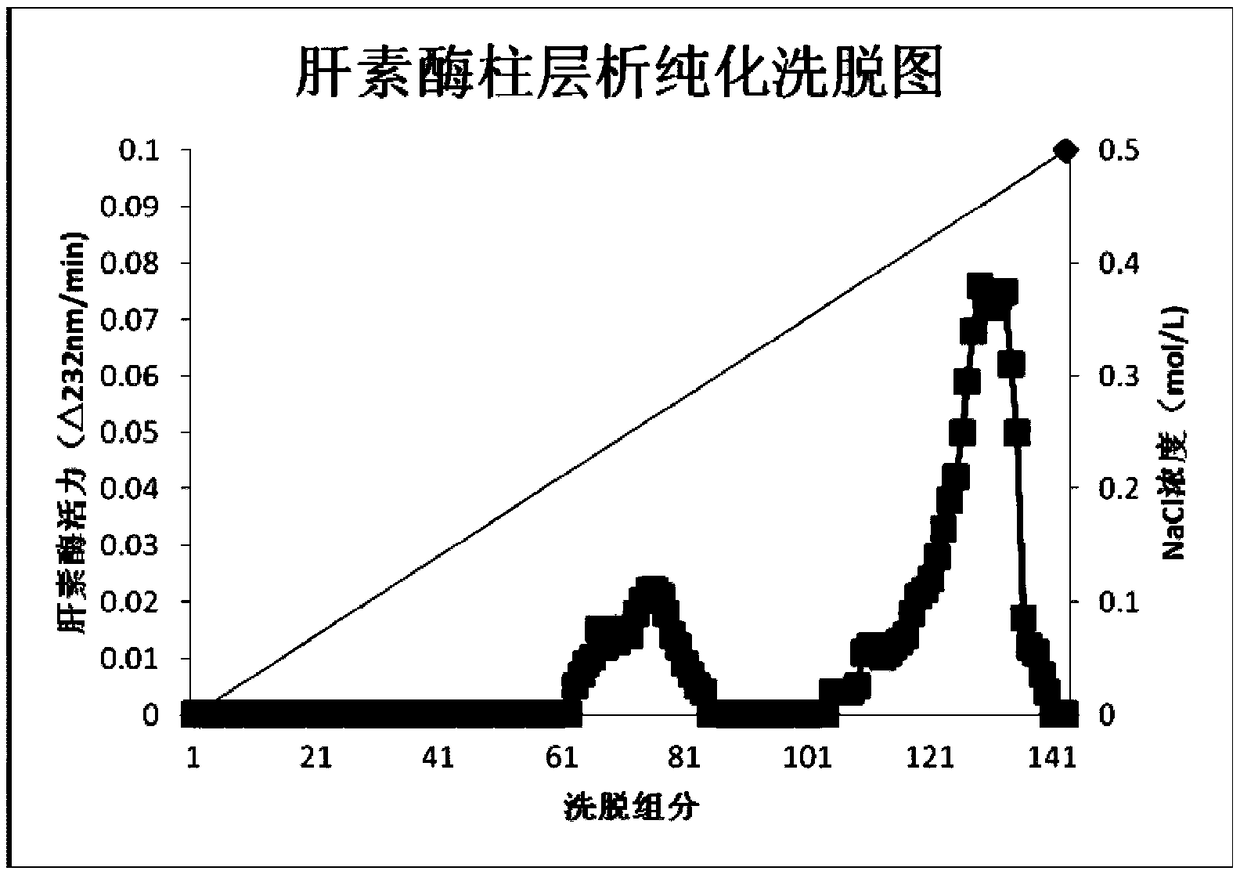

Image

Examples

Embodiment 1

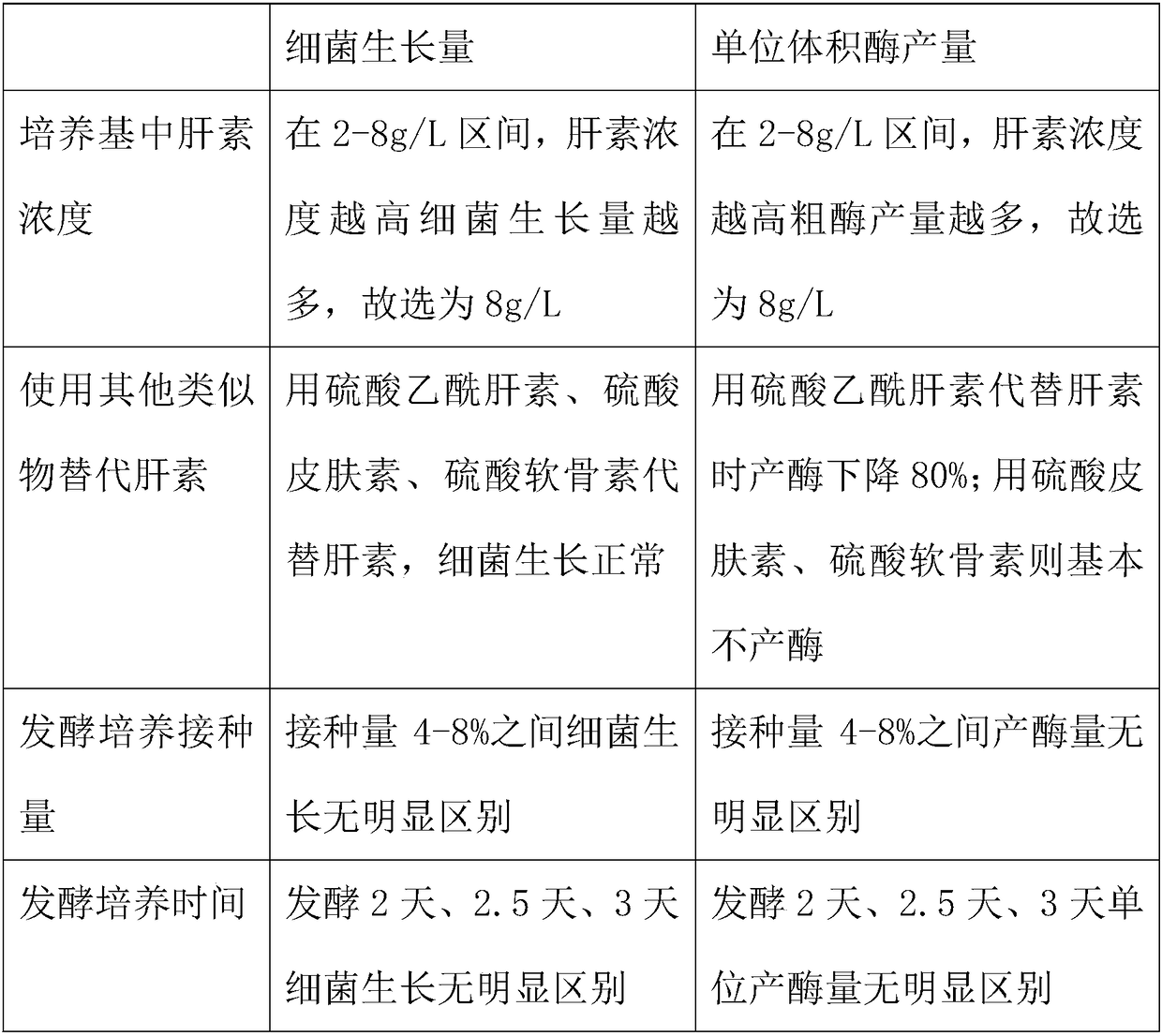

[0044] Fermentation preparation of heparinase: scrape two-ring bacteria from Flavobacterium heparin plate or slant and receive in 50ml seed culture medium (0.5% of beef extract, 1% of peptone, 0.5% of yeast powder, 0.5% of NaCl, pH 7.0), 23°C, 150rpm, cultured for 1 day. The 5% inoculum was inserted into the secondary seed medium and cultivated under the same conditions for 1 day. Then insert 4L fermentation medium according to 5% inoculum amount and culture for 2 days. Fermentation medium composition: heparin 8g / L, K 2 HPO 4 2.5g / L, NaH 2 PO 4 2.5g / L, NH 4 Cl 2.0g / L, MgCl 2 0.5g / L, histidine 0.5g / L, methionine 0.5g / L, trace element NaMoO 3 , CuCl 2 , FeCl 2 、CoCl 2 , MnCl 2 , CaCl 2 1×10 each -4 M, pH 7.0. Cultured for 2 days at 23°C, 150 rpm. The bacterial solution was centrifuged at 10,000 rpm at 4°C for 30 minutes, and the precipitate was collected.

[0045] Suspend the enzyme-containing bacterial cells in 40ml sucrose solution at 4°C for 2 hours, centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com