High-efficiency, space-saving and energy-saving oven for synthetic leather

A space-saving, synthetic leather technology, applied in textiles and papermaking, etc., can solve the problem that the length of the oven cannot meet the requirements, and achieve the effects of maintaining a healthy environment, high drying efficiency, and accelerating air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

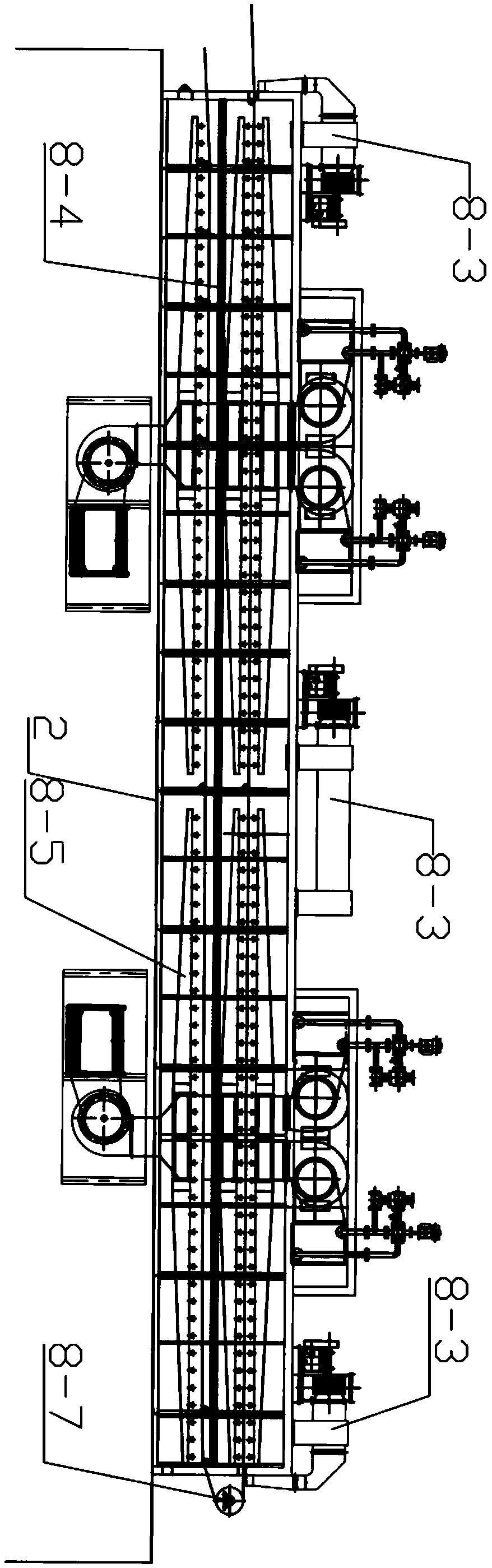

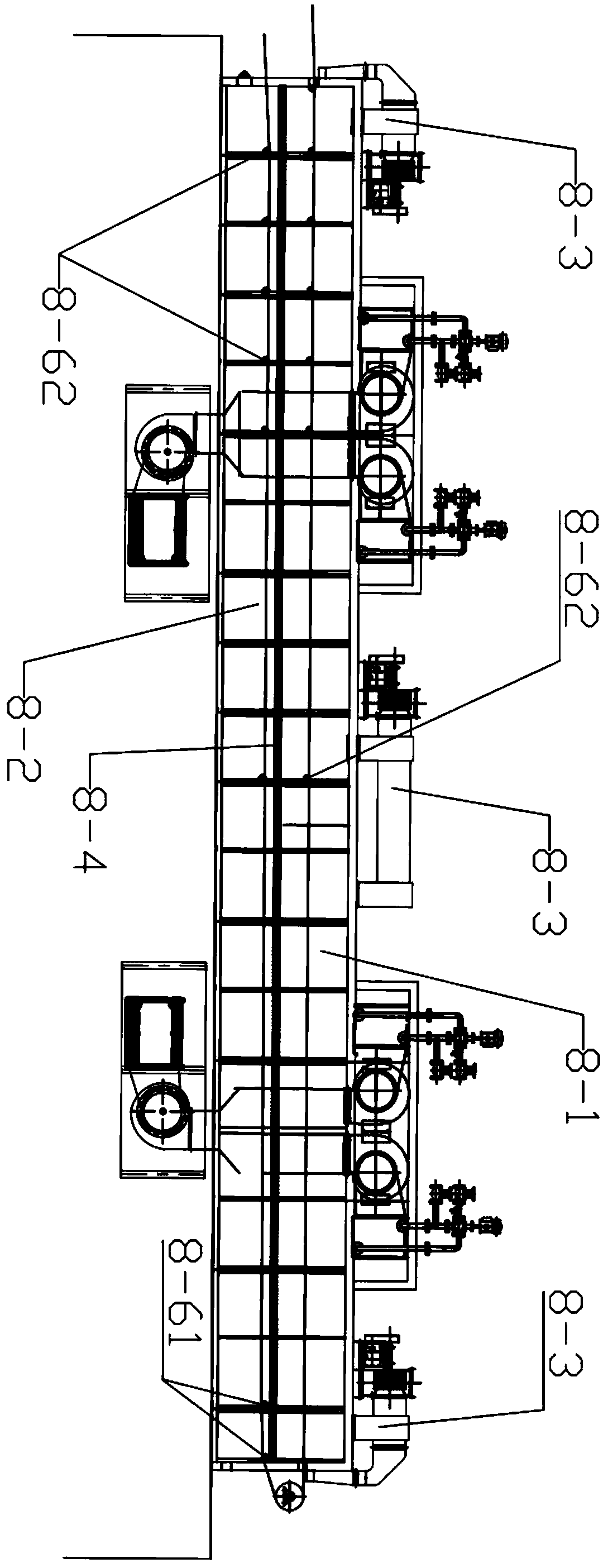

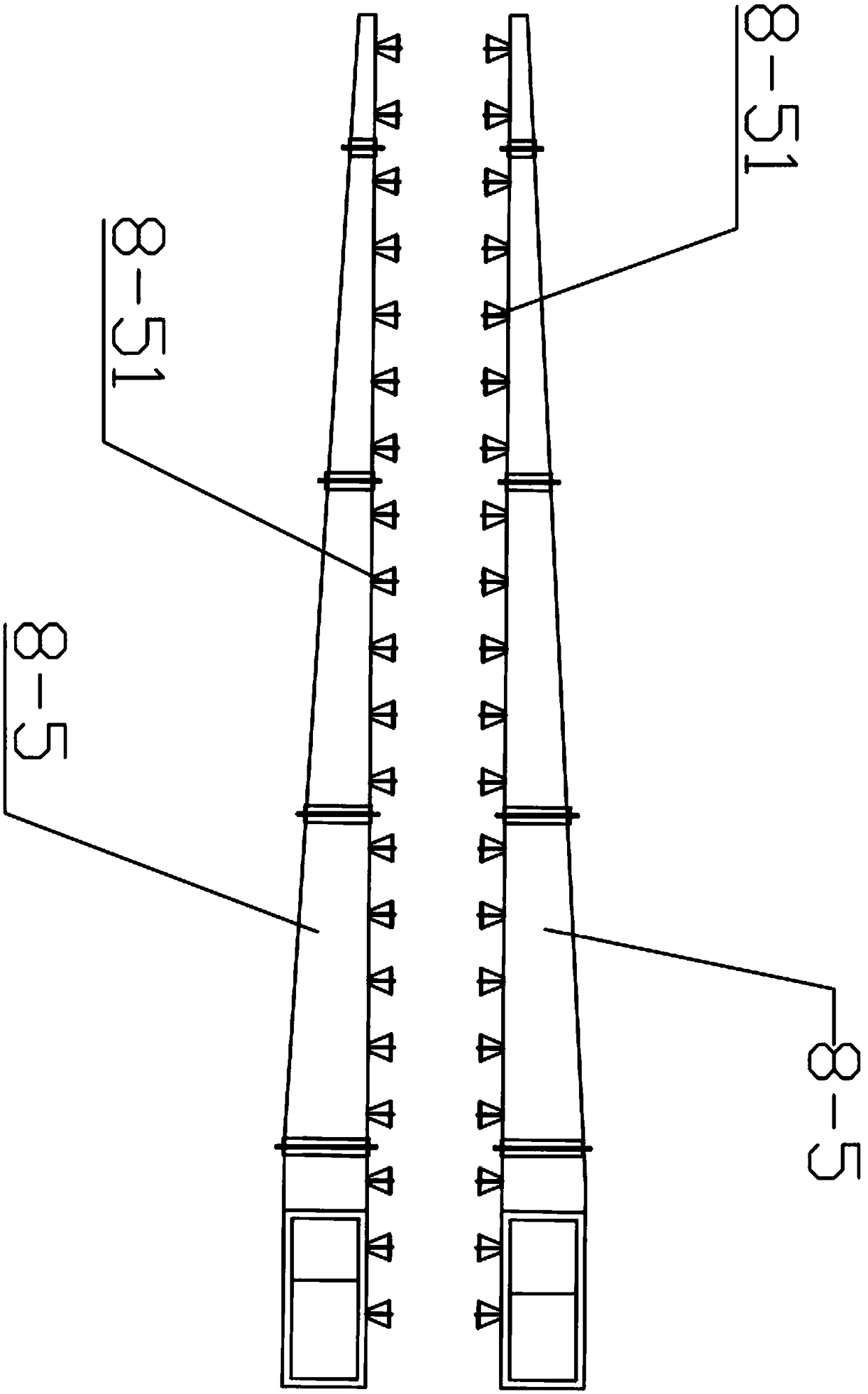

[0034] Such as Figures 1 to 3 As shown, a high-efficiency, space-saving and energy-saving oven for synthetic leather includes a shell and a drying cavity; the two ends and the middle of the high-efficiency, space-saving and energy-saving oven for synthetic leather are provided with air suction devices 8-3; One end of the high-efficiency, space-saving and energy-saving oven is provided with a reversing wheel 8-7; the drying cavity is elongated; the drying cavity is provided with a thermal insulation partition 8-4 to divide it into an upper layer The drying chamber 8-1 and the lower drying chamber 8-2; the bottom and the top of the upper drying chamber 8-1 are relatively provided with at least two air outlet plates 8-5, and the air outlet plates 8-5 and The blower is connected; the bottom of the lower drying chamber 8-2 is provided with at least one air outlet plate 8-5, and the air outlet plate 8-5 is connected with the blower; the upper drying chamber 8-1 is provided with At...

Embodiment 2

[0036] Such as Figures 1 to 3 As shown, a high-efficiency, space-saving and energy-saving oven for synthetic leather includes a shell and a drying cavity; both ends and the middle of the high-efficiency, space-saving and energy-saving oven for synthetic leather are provided with air suction devices 8-3; One end of the high-efficiency, space-saving and energy-saving oven is provided with a reversing wheel 8-7; the drying cavity is elongated; the drying cavity is provided with a thermal insulation partition 8-4 to divide it into an upper layer The drying chamber 8-1 and the lower drying chamber 8-2; the bottom and the top of the upper drying chamber 8-1 are relatively provided with at least two air outlet plates 8-5, and the air outlet plates 8-5 and The blower is connected; the bottom of the lower drying chamber 8-2 is provided with at least one air outlet plate 8-5, and the air outlet plate 8-5 is connected with the blower; the upper drying chamber 8-1 is provided with At le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com