Ore powder heating system, pouring asphalt concrete production device and production process

A heating system and mineral powder technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of insufficient heat exchange uniformity and adequacy, bad influence on the quality of asphalt concrete, affecting the quality stability of asphalt concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

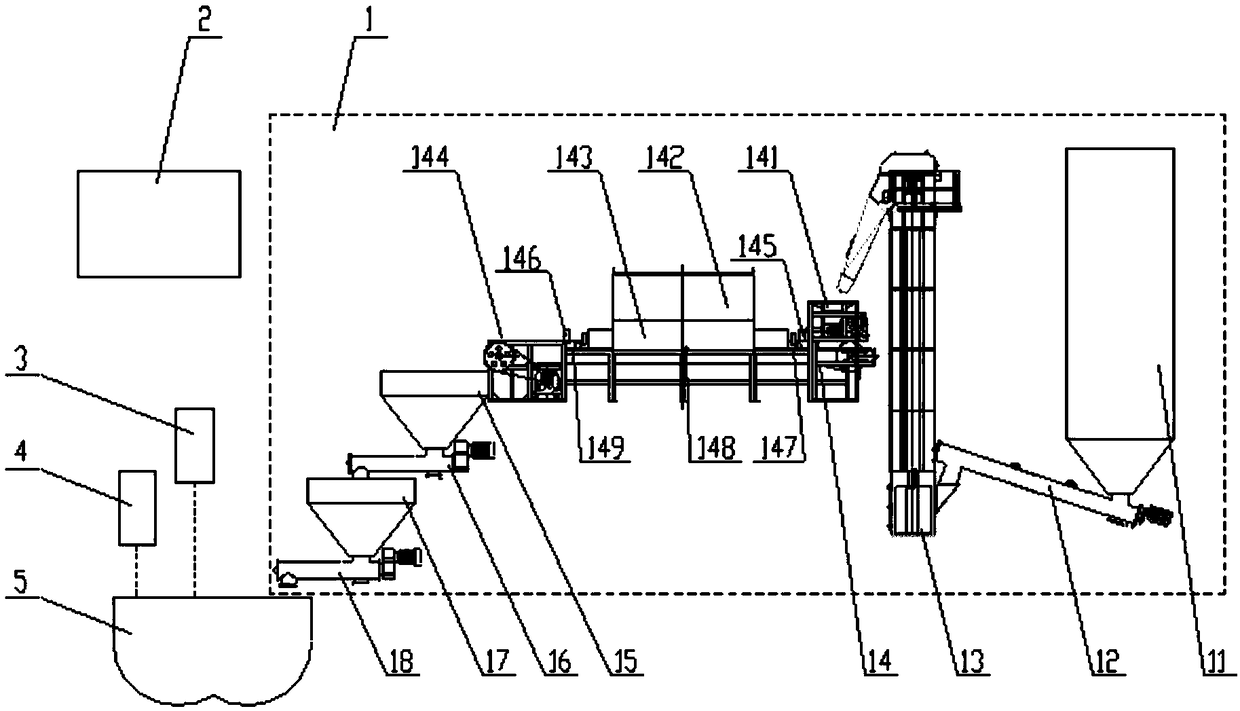

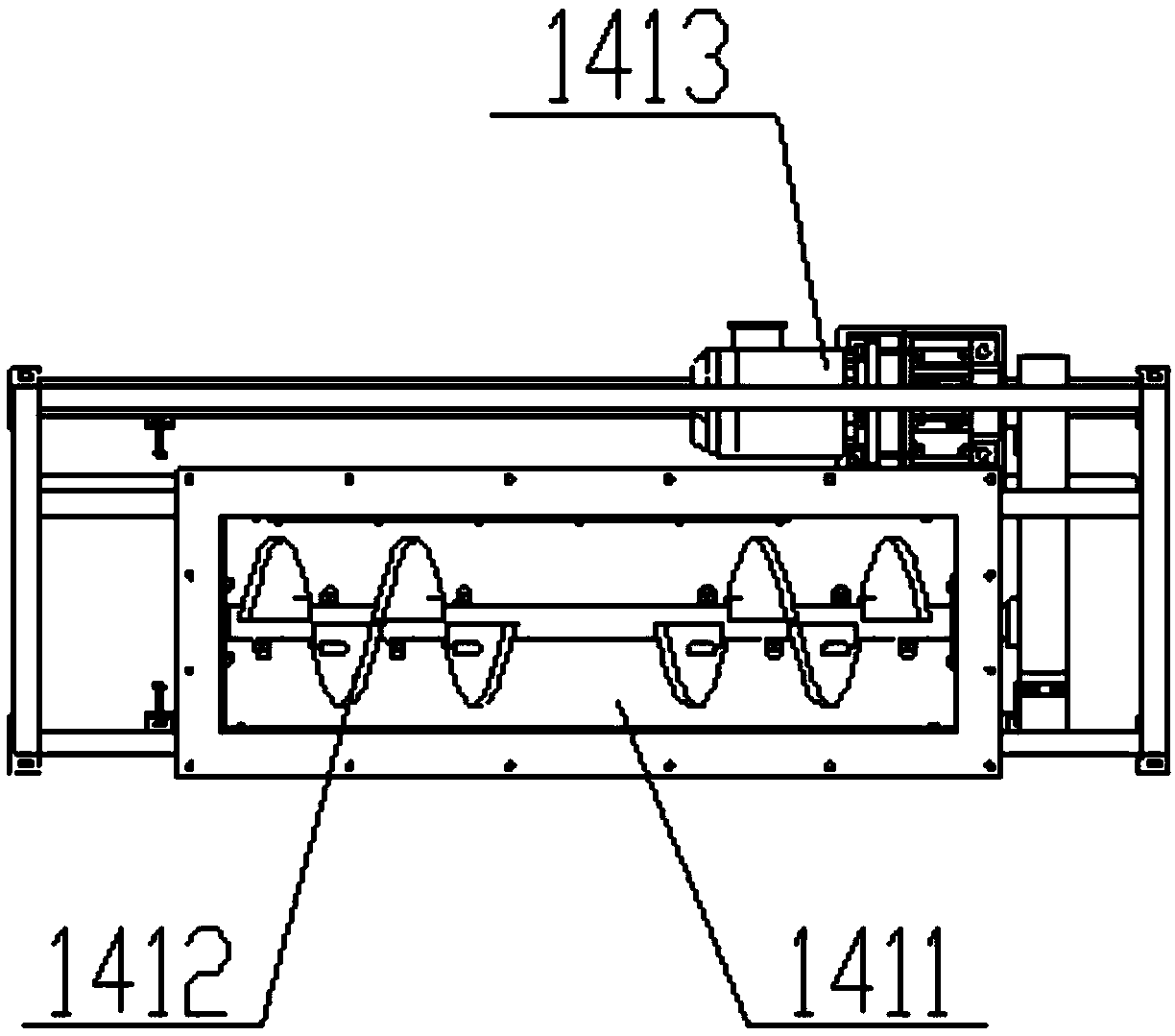

[0026] Such as figure 1 As shown, a pouring type asphalt concrete production equipment includes a mineral powder system 1, a control system 2, an aggregate system 3, an asphalt system 4, and a mixing system 5. The control system 2 is connected with the ore powder system 1, the aggregate system 3, the asphalt system 4 and the mixing system 5 respectively. The ore powder system 1, the aggregate system 3, and the asphalt system 4 provide raw materials to the mixing system 5 respectively. The ore powder system 1 includes a cold ore powder storage bin 11, a cold ore powder conveying screw 12, a cold ore powder elevator 13, a ore powder heating system 14, a hot ore powder storage bin 15, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap