Steel grid construction technology based on BIM lofting and three-dimensional scanning

A technology of three-dimensional scanning and construction technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of overall hoisting accuracy, safety and construction efficiency not being significantly improved, inconsistent lifting speed of steel grids, Problems such as the inapplicability of the installation of the steel grid frame, to achieve the effect of reducing labor input, efficient construction work, and saving measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

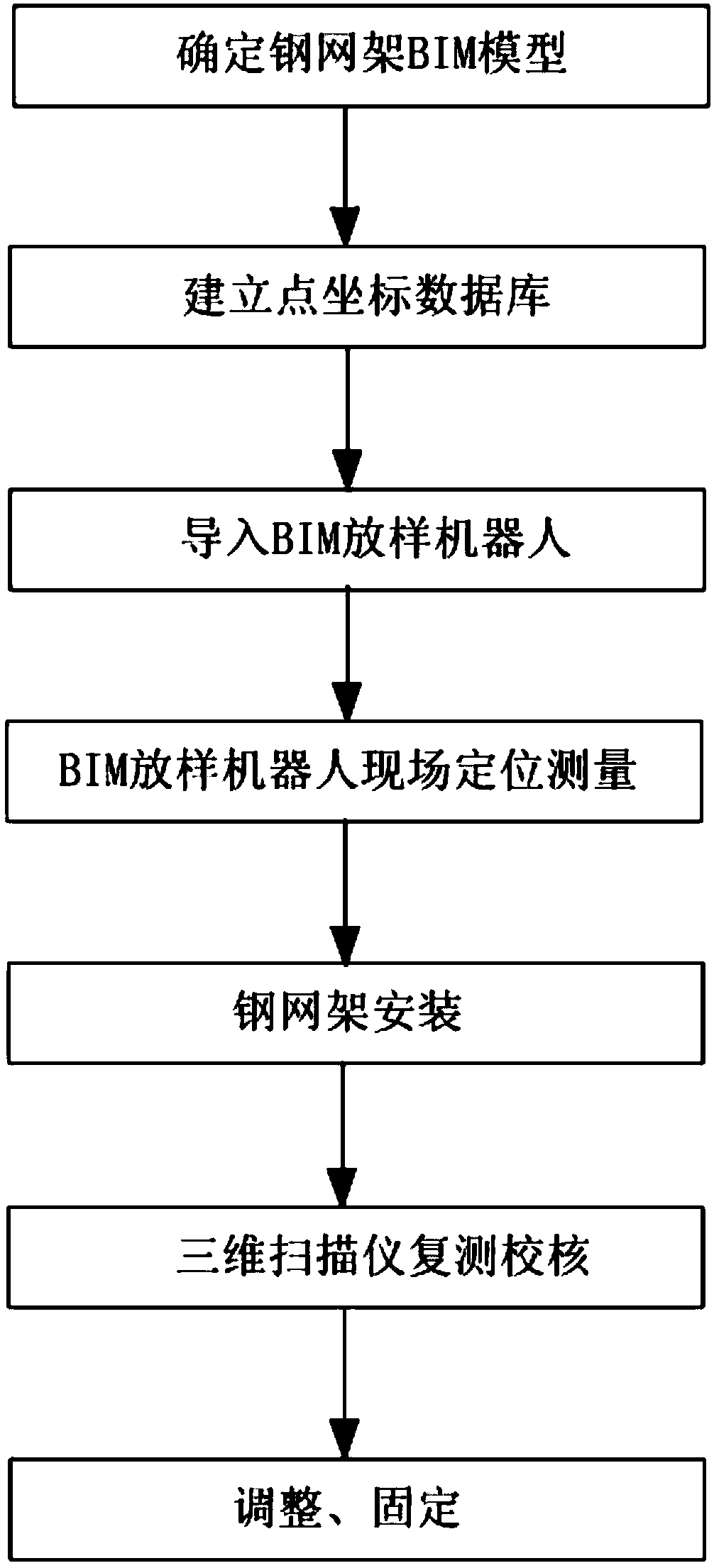

[0040] Such as figure 1 As shown, the steel grid construction process based on BIM lofting and 3D scanning includes the following steps:

[0041] (1) Determine the BIM model of the steel grid:

[0042] The steel grid model is optimized according to the layout principles, clearance requirements and deepening standards, and the BIM model of the steel grid is determined after joint review by professional engineers and design units.

[0043] (2) Establish point coordinate database:

[0044] According to the plane positioning and elevation data, the coordinate points to be set out on site are set in the steel grid BIM model as the reference points, and the number of reference points is more than 2. Then perform data processing on the points in each area, including the coordinate points of the BIM model of the steel grid, the coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com