Hydrogen mixed working medium power system

A power system and mixed working medium technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of small power generation of generators, low energy conversion rate of the system, and limited promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

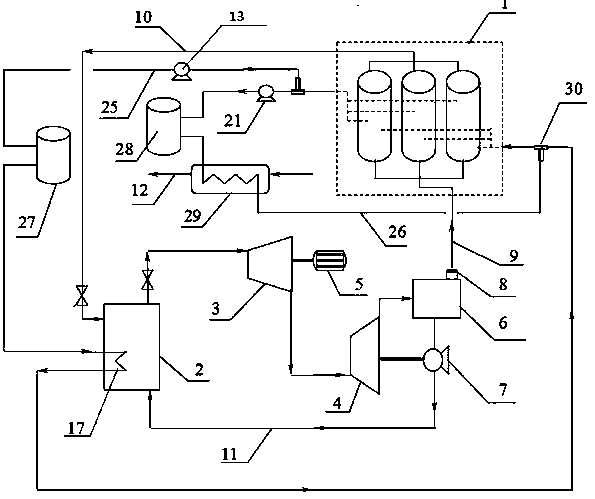

[0027] Hydrogen mixed working fluid power system of the present invention such as figure 1 As shown, it includes a hydrogen reaction bed unit 1, a mixed gasifier 2, a mixed gas expander 3, a liquid-carrying expander 4, a generator 5, a gas-liquid separator 6, an air heat exchange pipeline 12, and a cooling hydrogen pipeline 25 , Heating hydrogen pipeline 26, No. 1 hydrogen intermediate tank 27, No. 2 hydrogen intermediate tank 28, air heat exchanger 29, heat exchange medium high pressure hydrogen circulation pump 21, heat exchange medium low pressure hydrogen circulation pump 13 and liquid booster pump 7 . The gas mixture expander is connected to the shaft of the generator, and the electricity generated by the generator is connected to the grid. The liquid-carrying expander is connected to the liquid pressurizing pump with 7 shafts, and the liquid pressurizing pump is driven to pressurize the circulating liquid nitrogen. The mixed gasifier 2 is provided with a heat exchange ...

Embodiment 2

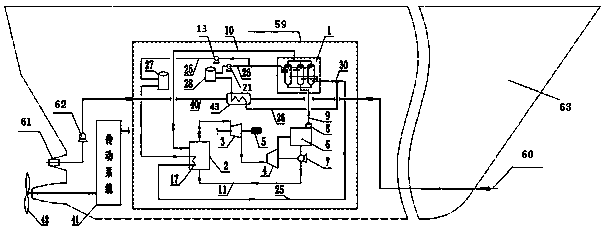

[0039] Another embodiment of the present invention is as image 3 As shown, the hydrogen mixed working medium power system is installed on the ship 63, and is used as the seawater energy utilization system 59 of the ship. The seawater energy utilization system 59 includes a hydrogen reaction bed unit 1, a mixed gasifier 2, a mixed gas expander 3, a liquid-laden expander 4, a generator 5, a gas-liquid separator 6, a seawater pipeline 40, and a cooling hydrogen pipeline 25 , Heating hydrogen pipeline 26, No. 1 hydrogen intermediate tank 27, No. 2 hydrogen intermediate tank 28, seawater heat exchanger 43, heat exchange medium high pressure hydrogen circulation pump 21, heat exchange medium low pressure hydrogen circulation pump 13 and liquid pressurization pump 7 . The gas mixture expander is connected to the shaft of the generator, and the electricity generated by the generator is connected to the grid. The liquid-carrying expander is connected to the liquid pressurizing pump ...

Embodiment 3

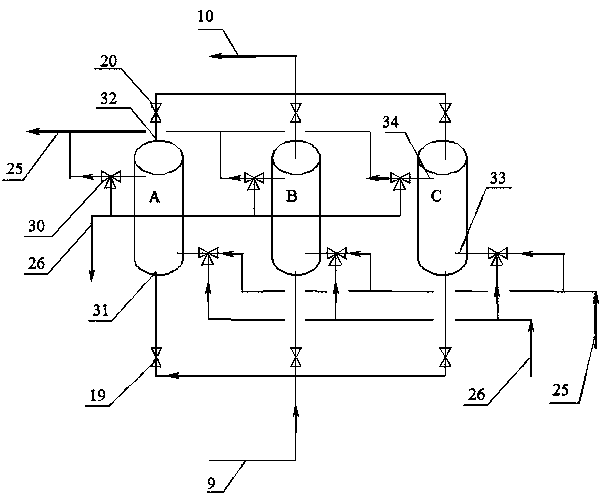

[0042] The third embodiment of the present invention is as Figure 4 As shown, it includes hydrogen reaction bed unit 1, hydrogen expander 57, organic working medium compressor 51, organic working medium expander 52, flue gas heat exchange pipeline 56, cooling hydrogen pipeline 25, heating hydrogen pipeline 26, flue gas Gas heat exchange center 53 , organic working medium heat exchanger 54 , organic working medium heat exchange center 55 , flue gas heat exchanger 58 and generator 5 . Such as figure 2 As shown, each hydrogen reaction bed of the hydrogen reaction bed unit is respectively provided with a low pressure hydrogen inlet 31 , a high pressure hydrogen outlet 32 , a heat exchange hydrogen inlet 33 and a heat exchange hydrogen outlet 34 . The heat exchange hydrogen outlet of the hydrogen reaction bed of the hydrogen reaction bed unit 1 is divided into two paths through the three-way valve 30, and one path passes through the cooling hydrogen pipeline 25, passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com