Automobile exhaust pipe

A technology of automobile exhaust and exhaust pipe, which is applied in the field of auto parts, can solve the problems of affecting the life of automobile exhaust pipe, vibration of automobile exhaust pipe, and increasing the noise of the whole vehicle, so as to suppress the vibration of the shell structure and prevent The effect of heat dissipation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

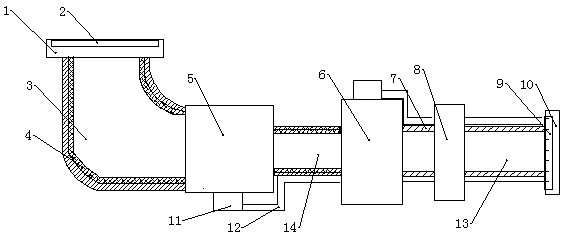

[0015] like figure 1 Shown, a kind of automobile exhaust pipe, it comprises connector 1, and described connector 1 is provided with fixing ring 2, and the bottom of described connector 1 is connected with front exhaust pipe 3, and described front row The tail of the air pipe 3 is provided with a three-way catalytic converter 5, and the rear of the three-way catalytic converter 5 is provided with a middle exhaust pipe 14, and the inner walls of the front exhaust pipe 3 and the middle exhaust pipe 14 are from the inside to the A heat insulation layer 4 and a sound-absorbing coating 7 are arranged on the outside in sequence, a particle trap 6 is arranged at the tail of the middle exhaust pipe 14, and a rear exhaust pipe 13 is arranged behind the particle trap 6, The inner wall of the rear exhaust pipe 13 is provided with a sound-absorbing coating 7 , the middle part of the rear exhaust pipe 13 is provided with a muffler 8 , and the tail of the rear exhaust pipe 13 is provided wit...

Embodiment 2

[0018] like figure 1 Shown, a kind of automobile exhaust pipe, it comprises connector 1, and described connector 1 is provided with fixing ring 2, and the bottom of described connector 1 is connected with front exhaust pipe 3, and described front row The tail of the air pipe 3 is provided with a three-way catalytic converter 5, and the rear of the three-way catalytic converter 5 is provided with a middle exhaust pipe 14, and the inner walls of the front exhaust pipe 3 and the middle exhaust pipe 14 are from the inside to the A heat insulation layer 4 and a sound-absorbing coating 7 are arranged on the outside in sequence, a particle trap 6 is arranged at the tail of the middle exhaust pipe 14, and a rear exhaust pipe 13 is arranged behind the particle trap 6, The inner wall of the rear exhaust pipe 13 is provided with a sound-absorbing coating 7 , the middle part of the rear exhaust pipe 13 is provided with a muffler 8 , and the tail of the rear exhaust pipe 13 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com