Four-stroke four-cylinder opposed one-way rotary engine and control method thereof

A one-way rotation, four-stroke technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of insufficient combustion of oil cylinders, large exhaust gas emissions, and low heat engine efficiency of internal combustion engines, and achieve full combustion, low exhaust gas emissions, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

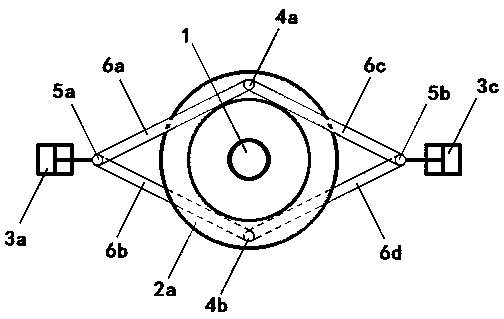

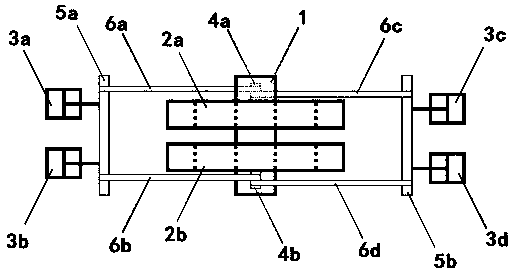

[0035] see figure 1 and figure 2 As shown, a four-stroke four-cylinder opposed one-way rotary engine includes an output shaft 1, a first one-way wheel 2a, a second one-way wheel 2b, a first oil cylinder 3a, a second oil cylinder 3b, a third oil cylinder 3c, The fourth oil cylinder 3d, the first connecting rod 5a, the second connecting rod 5b, the first push-pull rod 6a, the second push-pull rod 6b, the third push-pull rod 6c and the fourth push-pull rod 6d.

[0036] Both the first one-way wheel 2a and the second one-way wheel 2b adopt the applicant’s previous application number 201821139491.8 "a kind of one-way impact wheel" patent; the first one-way wheel 2a and The second one-way wheels 2b are both sleeved on the output shaft 1, and the effective rotation directions of the first one-way wheels 2a and the second one-way wheels 2b are the same; the first one-way wheels The upper or lower end of the outer surface of 2a is provided with a first hinge point 4a, and the lower o...

Embodiment 2

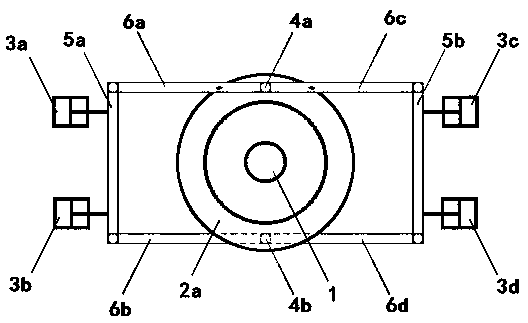

[0045] see image 3 and Figure 4 As shown, a four-stroke four-cylinder opposed one-way rotary engine includes an output shaft 1, a first one-way wheel 2a, a second one-way wheel 2b, a first oil cylinder 3a, a second oil cylinder 3b, a third oil cylinder 3c, The fourth oil cylinder 3d, the first connecting rod 5a, the second connecting rod 5b, the first push-pull rod 6a, the second push-pull rod 6b, the third push-pull rod 6c and the fourth push-pull rod 6d.

[0046] Both the first one-way wheel 2a and the second one-way wheel 2b adopt the applicant’s previous application number 201821139491.8 "a kind of one-way impact wheel" patent; the first one-way wheel 2a and The second one-way wheels 2b are both sleeved on the output shaft 1, and the effective rotation directions of the first one-way wheels 2a and the second one-way wheels 2b are the same; the first one-way wheels The upper or lower end of the outer surface of 2a is provided with a first hinge point 4a, and the lower o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com