Nozzle with non-weft cloth punched throat liner

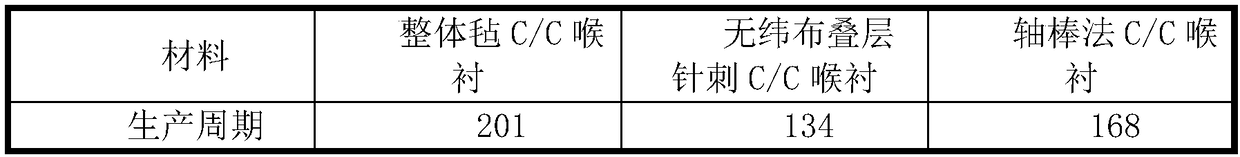

A technology without weft cloth and throat liner, which is applied in the field of solid rocket motor nozzles, can solve the problems that the nozzles are difficult to meet the needs of mass production of tactical missiles, the cost of carbon/carbon composite materials is high, and the working pressure of the engine is long. Achieve the effect of high degree of completion, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

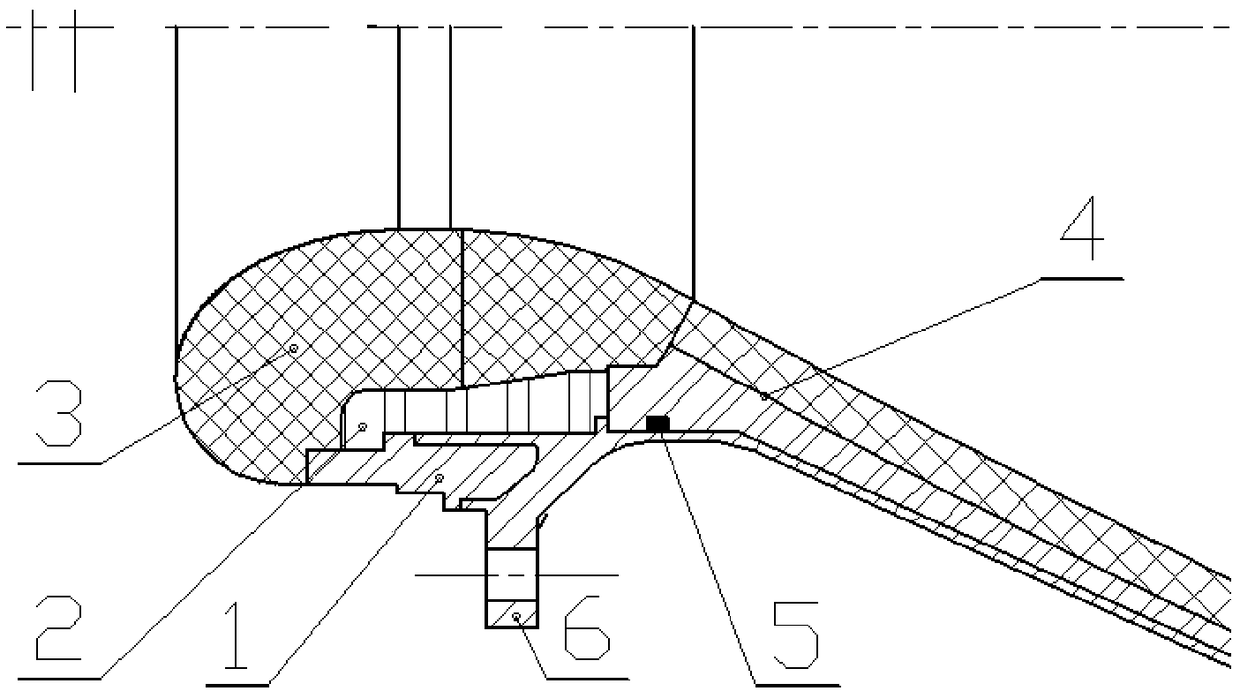

[0022] The invention provides a needle-punched throat liner nozzle without weft cloth, such as figure 1 As shown, it includes a fixed body insulation layer 1 , a back wall insulation layer 2 , a throat liner 3 , an expansion section insulation layer 4 , a sealing ring 5 and a nozzle housing 6 .

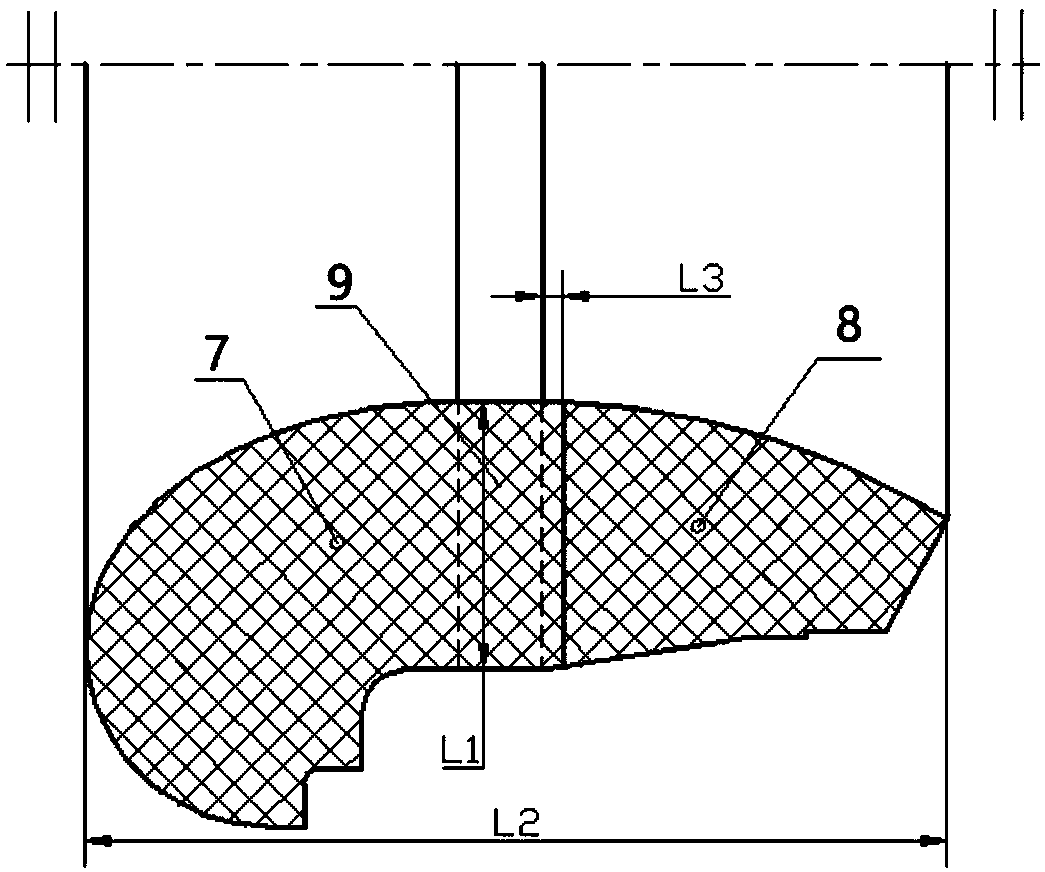

[0023] Such as figure 2 As shown, the throat liner 3 is a segmented structure, which is divided into the front segment 7 of the throat liner and the rear segment 8 of the throat liner. The segmented position is within the range of 3 mm to 5 mm from the column structure 9 to the outlet of the nozzle, that is, L3 is in the range of 3 mm to 5 mm. Inside, the axial stress of the throat lining 3 can be effectively reduced, thereby greatly improving the safety margin of the throat lining 3. The ratio of the length of the throat liner 3 to the thickness of the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com