Furnace end capable of discharging water and residue easily

A technology for removing residues and burners, which is applied in the field of burners that are easy to drain and discharge residues. It can solve the problems of increasing manufacturing costs, affecting ignition, and excessive exhaust gas emissions, so as to achieve comfortable use environment, improve efficiency, and reduce ambient temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

[0015] In this embodiment, the flow direction of the air in the main ventilation pipe 4 is taken as the rear, and vice versa as the front.

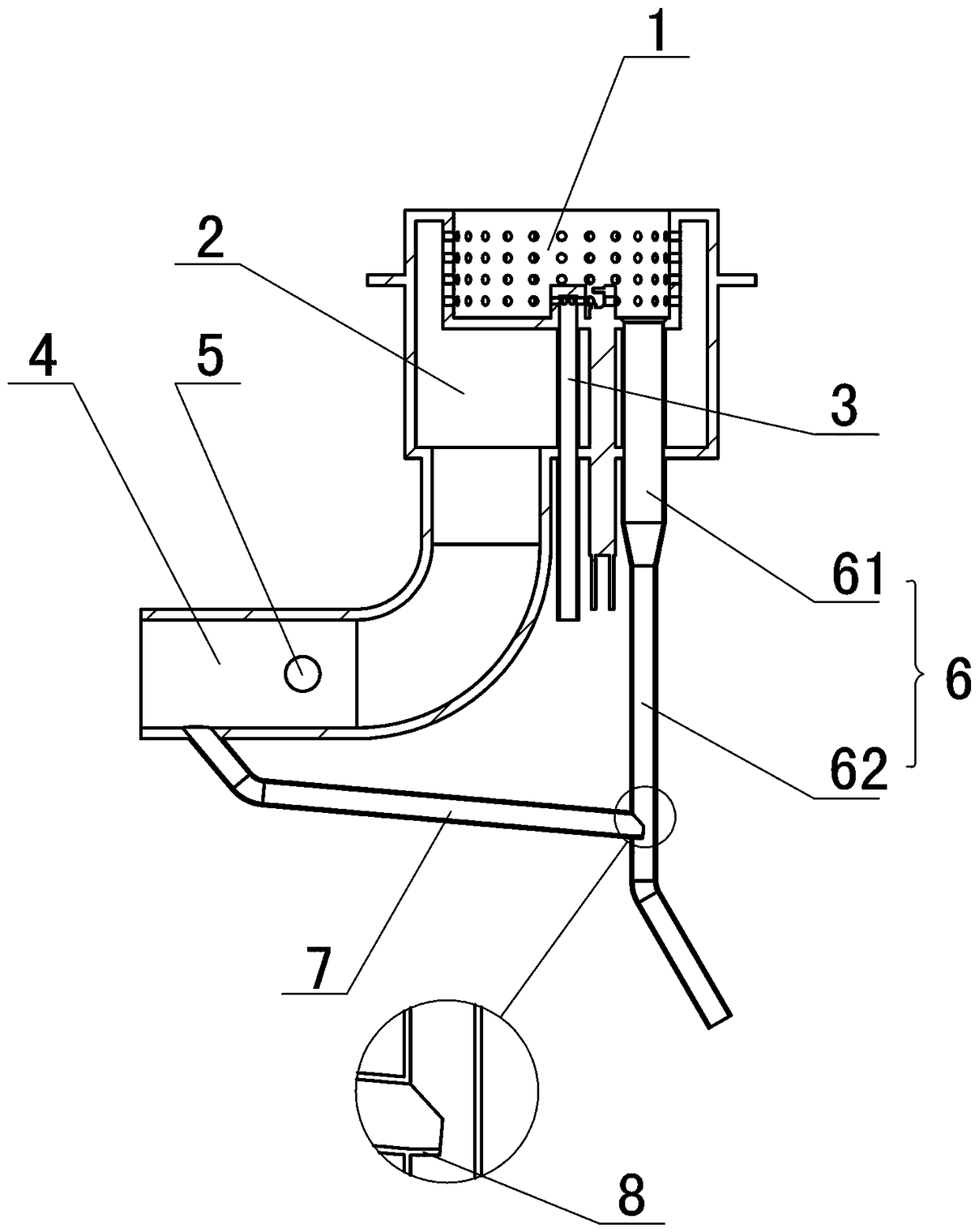

[0016] Such as figure 1 As shown, the present invention provides a burner that is easy to drain and discharge residues, including a combustion chamber 1 and an air mixing chamber 2 communicated with the combustion chamber 1. In this embodiment, the combustion chamber 1 is located inside the air mixing chamber 2, and the combustion chamber 1 The side wall is provided with a number of ventilation holes, and the bottom of the combustion chamber 1 is connected with a kindling inlet pipe 3 . The wind and air mixing chamber 2 is also communicated with the main fire ventilation pipe 4, and the main fire ventilation pipe 4 is provided with a main fire air inlet 5. The bottom of combustion chamber 1 communicates with drainpipe 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com