A Corrosion Resistance Evaluation Method of Low Alloy Steel Used in Polar Marine Environment

A low-alloy steel, marine environment technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of inconvenient rapid screening of corrosion-resistant steel, long experimental period, etc., to achieve short experimental period, variety Less and less expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

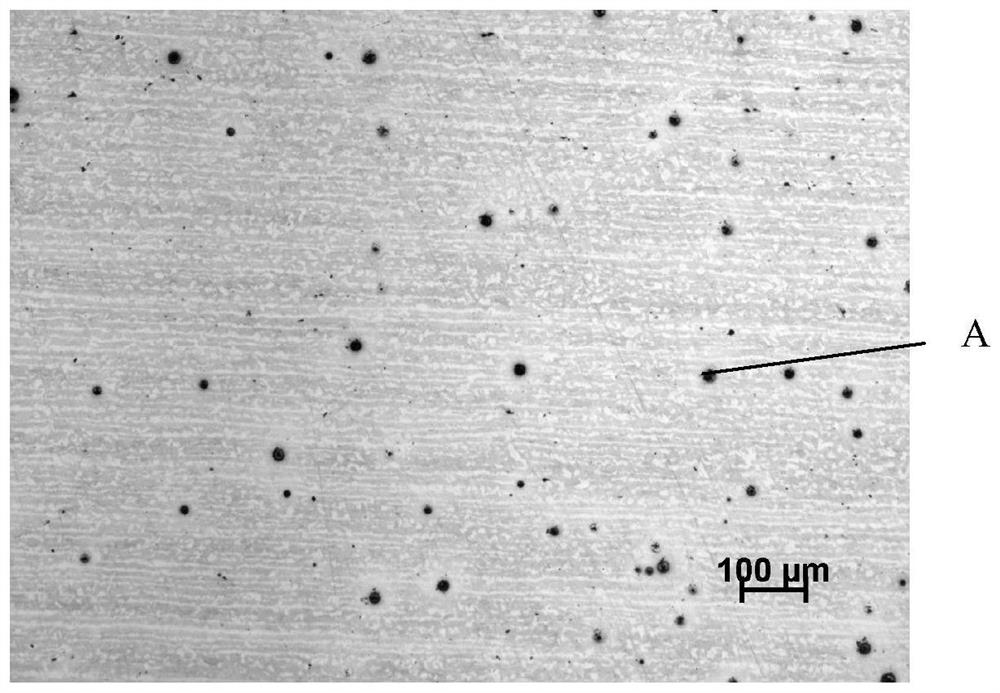

[0028] The ordinary ship plate steel AH36 is sampled along the rolling direction, processed into a metallographic sample, polished on 180#, 400#, 600#, 800#, 1200# sandpaper by the cross method, and polished on a grinding and polishing machine . Measure 500mL of deionized water and 500mL of absolute ethanol, mix them well, measure 45-55mL of hydrochloric acid (mass fraction 37%) with a density of 1.19g / ml and add it to the mixture, add 0.8g of CuCl, 0.4g of SnCl 2 , 28g of FeCl 3 , stirred, and the corrosion solution was obtained after all the solution was dissolved. Immerse the polished surface of the sample in the prepared corrosion solution, the temperature of the corrosion solution is 25°C, and the treatment time is 8 seconds. Take out the sample and rinse it with deionized water, and dry the sample quickly with a hair dryer. The sample is observed under a metallographic microscope, magnified 100 times, and the number of pitting sources of inclusions is counted. Take t...

Embodiment 2

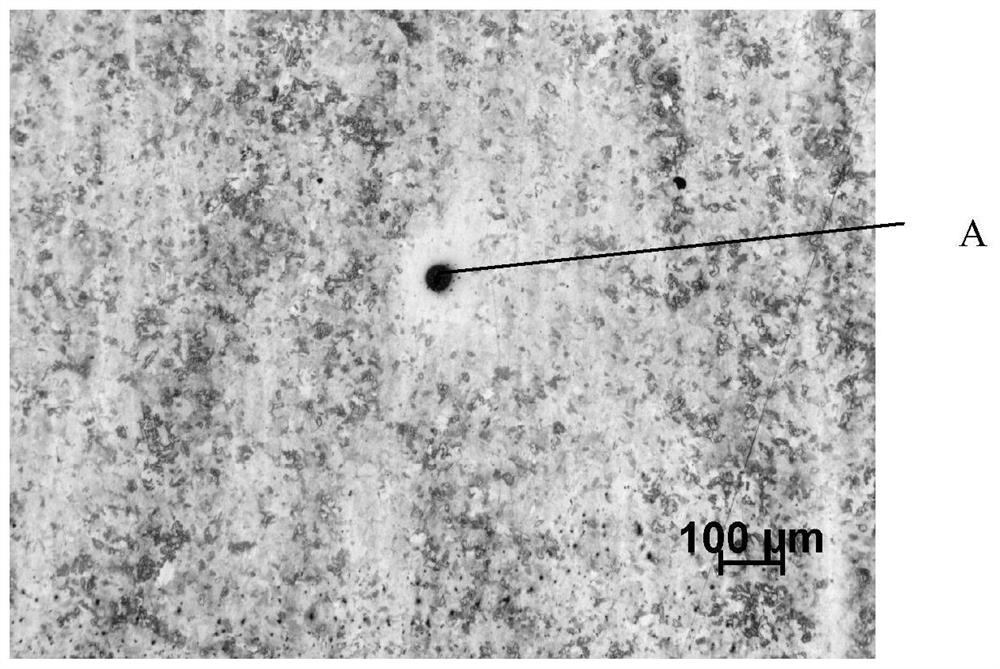

[0030] The steel grade 1 (AH36) of the special smelting method was sampled along the rolling direction, processed into a metallographic sample, and polished on 180#, 400#, 600#, 800#, 1200# sandpaper in the cross method, and Polish on a grinder. Measure 500mL of deionized water and 500mL of absolute ethanol, mix them well, measure 45-55mL of hydrochloric acid (mass fraction 37%) with a density of 1.19g / ml and add it to the mixture, add 0.8g of CuCl, 0.4g of SnCl 2 , 28g of FeCl 3 , stirred, and the corrosion solution was obtained after all the solution was dissolved. Immerse the polished surface of the sample in the prepared corrosion solution, the temperature of the corrosion solution is 25°C, and the time is 8 seconds. Take out the sample and rinse it with deionized water, and dry the sample quickly with a hair dryer. The sample is observed under a metallographic microscope, magnified 100 times, and the number of pitting sources of inclusions is counted. The field of vie...

Embodiment 3

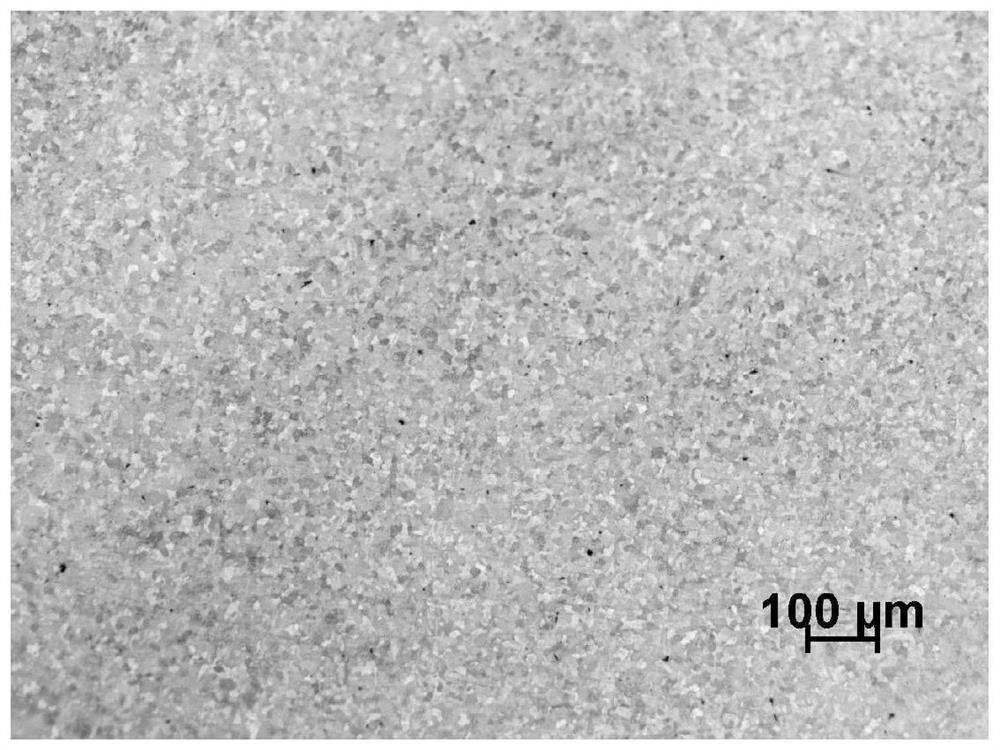

[0032] The steel type 2 (AH36) of the special smelting method is sampled along the rolling direction, processed into a metallographic sample, and polished on 180#, 400#, 600#, 800#, 1200# sandpaper in the cross method, and Polish on a grinder. Measure 500mL of deionized water and 500mL of absolute ethanol, mix them well, measure 45-55mL of hydrochloric acid (mass fraction 37%) with a density of 1.19g / ml and add it to the mixture, add 0.8g of CuCl, 0.4g of SnCl 2 , 28g of FeCl 3, stirred, and the corrosion solution was obtained after all the solution was dissolved. Immerse the polished surface of the sample in the prepared corrosion solution, the temperature of the corrosion solution is 25°C, and the time is 8 seconds. Take out the sample and rinse it with deionized water, and dry the sample quickly with a hair dryer. The sample is observed under a metallographic microscope, magnified 100 times, and the number of pitting sources of inclusions is counted. The field of view w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com