Electrodeposition silver layer copper alloy/titanium alloy heterogeneous bimetallic connection method

A bimetallic connection, titanium alloy technology, applied in the direction of improving process efficiency, can solve the problems of low connection strength and poor interface bonding, and achieve the effect of high interface bonding strength, filling holes, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

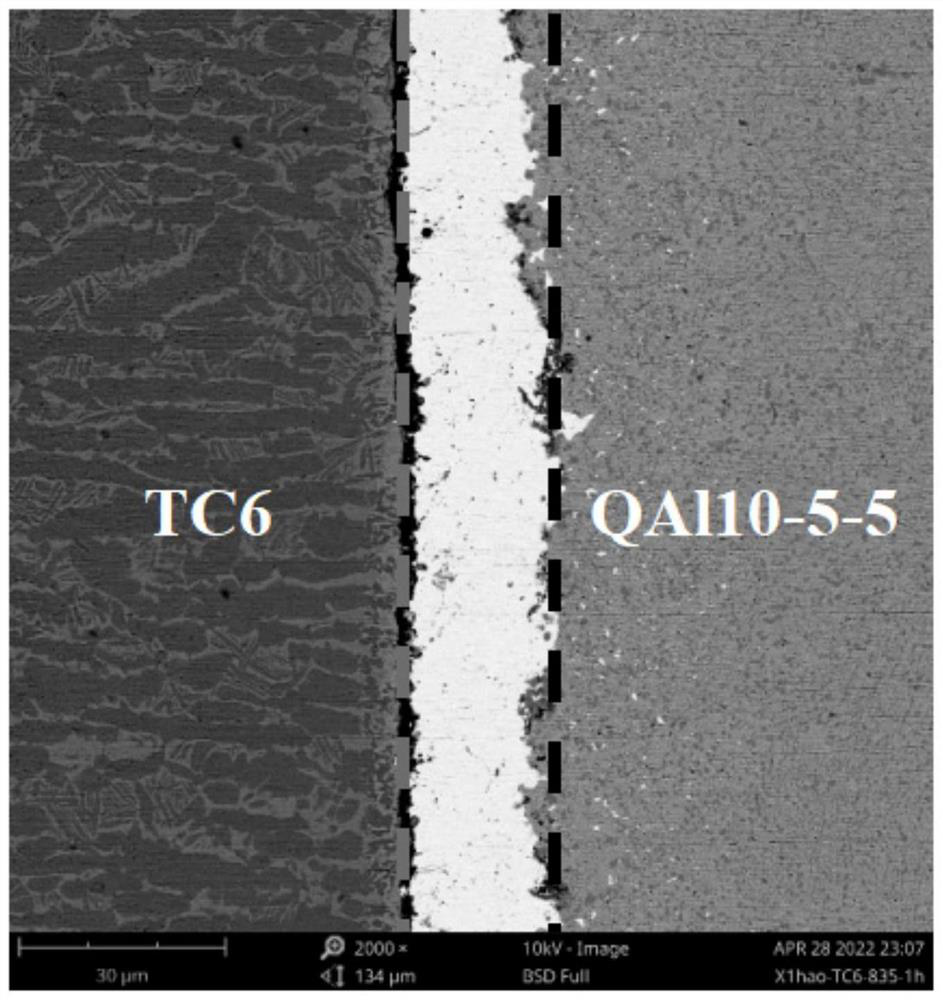

[0032] To prepare aluminum bronze / titanium alloy bimetal, aluminum bronze with grade QAl10-5-5 (hereinafter referred to as QAl10-5-5) and titanium alloy with trademark TC6 (hereinafter referred to as TC6) are processed into a Φ20mm×25mm cylinder. Mechanical grinding of QAl10-5-5 and TC6, ultrasonic cleaning in the order of deionized water, absolute ethanol, acetone, and deionized water, followed by pickling, soaking in 10% nitric alcohol for 30s, and then using The pretreated QAl10-5-5 and TC6 were obtained by cleaning with absolute ethanol for 5 min, and the TC6 was dried and stored for later use.

[0033] The pretreated QAl10-5-5 is electrodeposited. The specific process parameters are: the electrodeposition temperature is room temperature of 25°C, the pH value of the electrodeposition solution is 4.5, the current intensity is 0.5A, and the electrodeposition time is 25min. The silver layer thickness is 15 μm. It is post-processed, dried and stored for later use.

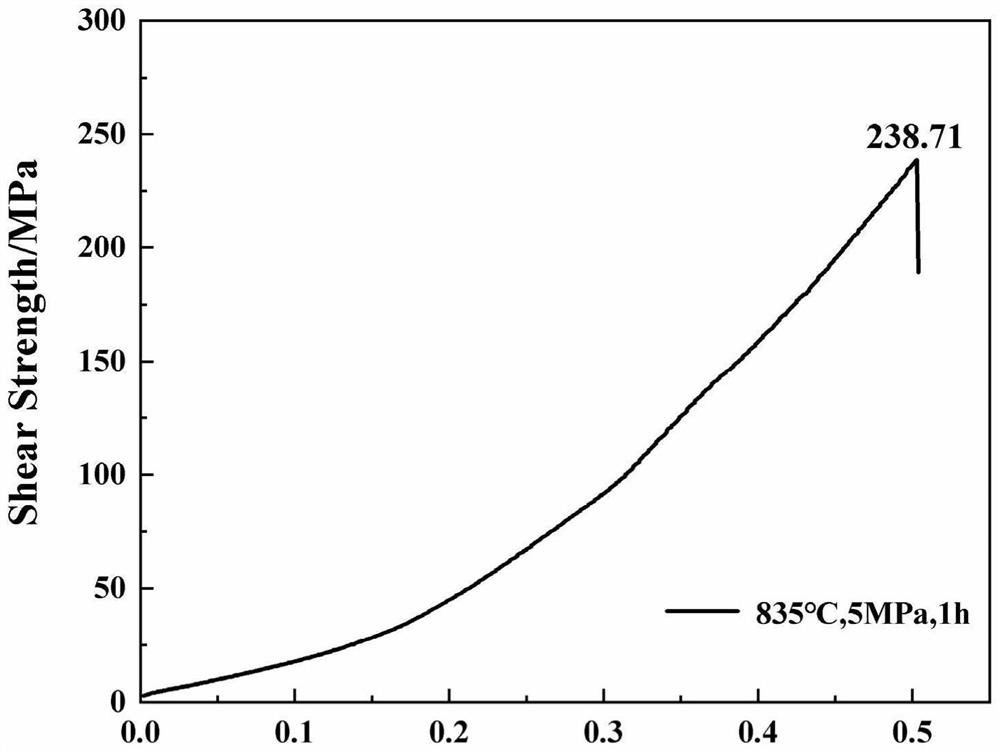

[0034] P...

Embodiment 2

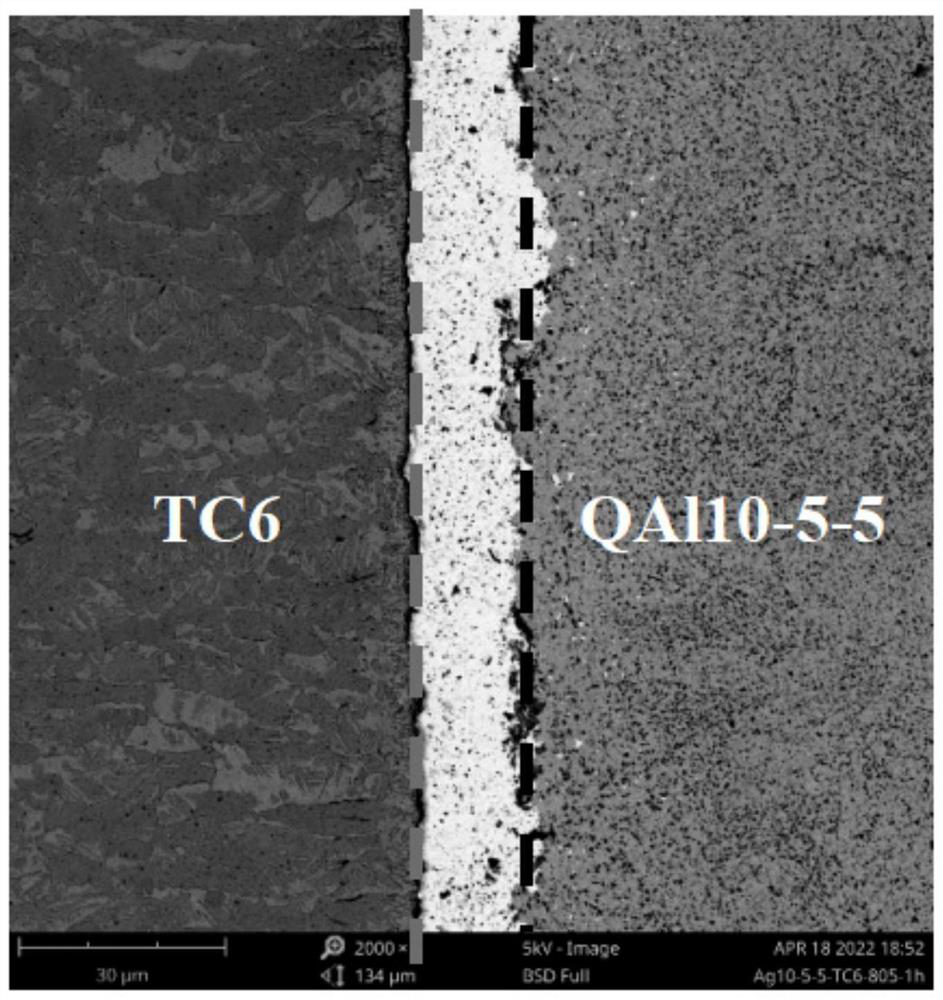

[0036]To prepare aluminum bronze / titanium alloy bimetal, aluminum bronze with grade QAl10-5-5 (hereinafter referred to as QAl10-5-5) and titanium alloy with trademark TC6 (hereinafter referred to as TC6) are processed into a Φ20mm×25mm cylinder. Mechanical grinding of QAl10-5-5 and TC6, ultrasonic cleaning in the order of deionized water, absolute ethanol, acetone, and deionized water, followed by pickling, soaking in 10% nitric alcohol for 30s, and then using The pretreated QAl10-5-5 and TC6 were obtained by cleaning with absolute ethanol for 5 min, and the TC6 was dried and stored for later use.

[0037] The pretreated QAl10-5-5 was electrodeposited, and the specific process parameters were: the electrodeposition temperature was room temperature 25°C, the pH value of the electrodeposition solution was 4.3, the current intensity was 0.5A, and the electrodeposition time was 25min. The silver layer thickness is 15 μm. It is post-processed, dried and stored for later use.

[0...

Embodiment 3

[0040] To prepare aluminum bronze / titanium alloy bimetal, aluminum bronze with grade QAl10-5-5 (hereinafter referred to as QAl10-5-5) and titanium alloy with trademark TC6 (hereinafter referred to as TC6) are processed into a Φ20mm×25mm cylinder. Mechanical grinding of QAl10-5-5 and TC6, ultrasonic cleaning in the order of deionized water, absolute ethanol, acetone, and deionized water, followed by pickling, soaking in 10% nitric alcohol for 30s, and then using The pretreated QAl10-5-5 and TC6 were obtained by cleaning with absolute ethanol for 5 min, and the TC6 was dried and stored for later use.

[0041] The pretreated QAl10-5-5 is electrodeposited. The specific process parameters are: the electrodeposition temperature is room temperature of 25°C, the pH value of the electrodeposition solution is 4.6, the current intensity is 0.5A, and the electrodeposition time is 25min. The silver layer thickness is 15 μm. It is post-processed, dried and stored for later use.

[0042] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com