High signal-to-noise ratio eddy thermal imaging detection method based on direction modulation

A technology with high signal-to-noise ratio and direction modulation, which can be used in material defect testing and other directions to solve problems such as poor detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

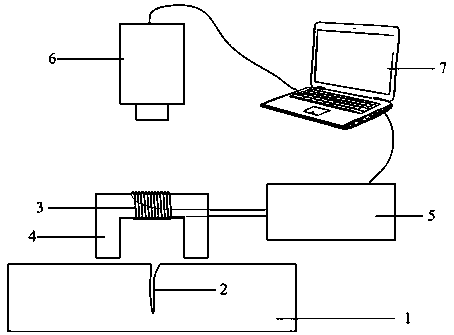

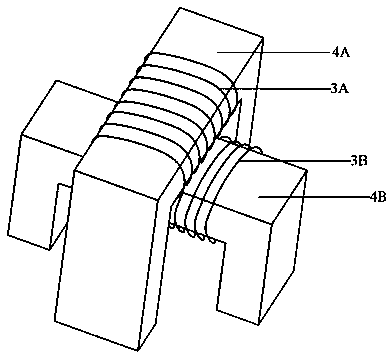

[0021] The structure of the eddy current thermal imaging system is as follows: figure 1 As shown, there is a crack 2 on the metal sample 1, the excitation coil 3 is wound on the ferrite core 4, and the alternating current is provided by the high-power high-frequency power supply 5, and the thermal imager 6 is located above the sample to observe the induction heating area , the software on the computer 7 controls the start and stop of the power supply 5, and at the same time collects the data of the thermal imager 6 for processing, analysis and display of results. Among them, the exciting coil 3 and the ferrite core 4 are composed of two sets of coils and magnetic cores whose excitation directions are perpendicular to each other. The structure is as follows: figure 2 As shown, the coil 3A is wound on the U-shaped magnetic core 4A, and the coil 3B is wound on the U-shaped magnetic core 4B. The induced eddy currents generated by the coil 3A and the coil 3B on the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com