Method for Determination of Nanoplastics Based on Cloud Point Extraction-Pyrolysis Gas Chromatography-Mass Spectrometry

A gas chromatography-mass spectrometry and thermal cracking technology, applied in the field of determination of nanoplastics based on cloud point extraction-thermal cracking gas chromatography-mass spectrometry, can solve the problems of insufficient reliability, time-consuming, laborious and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

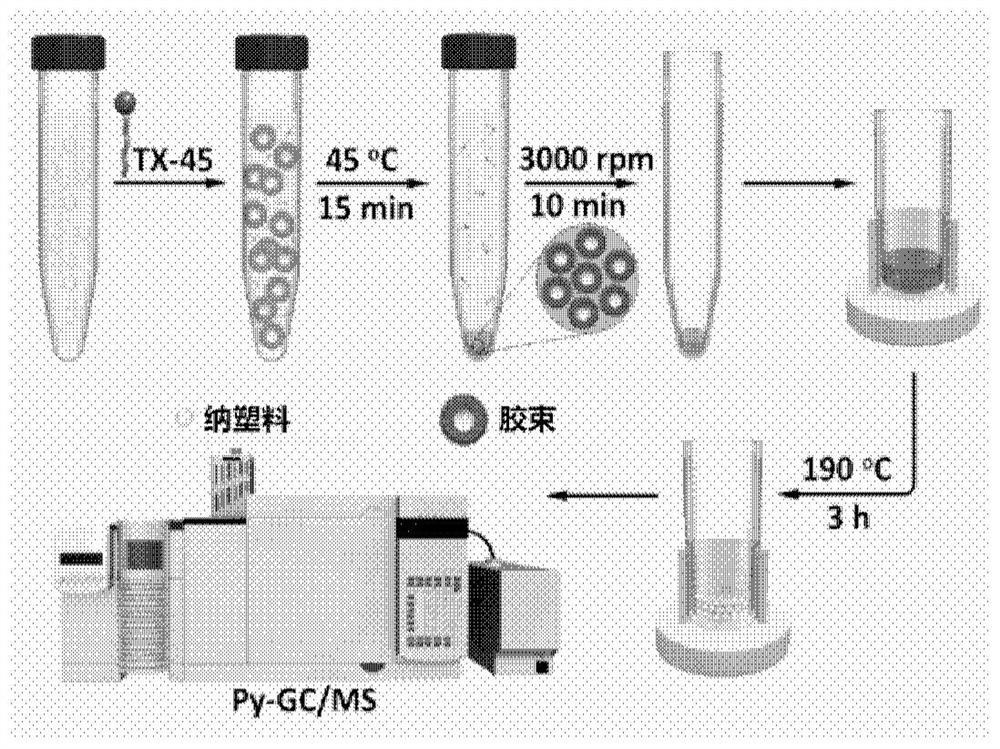

Method used

Image

Examples

Embodiment 1

[0029] Optimize cloud point extraction conditions:

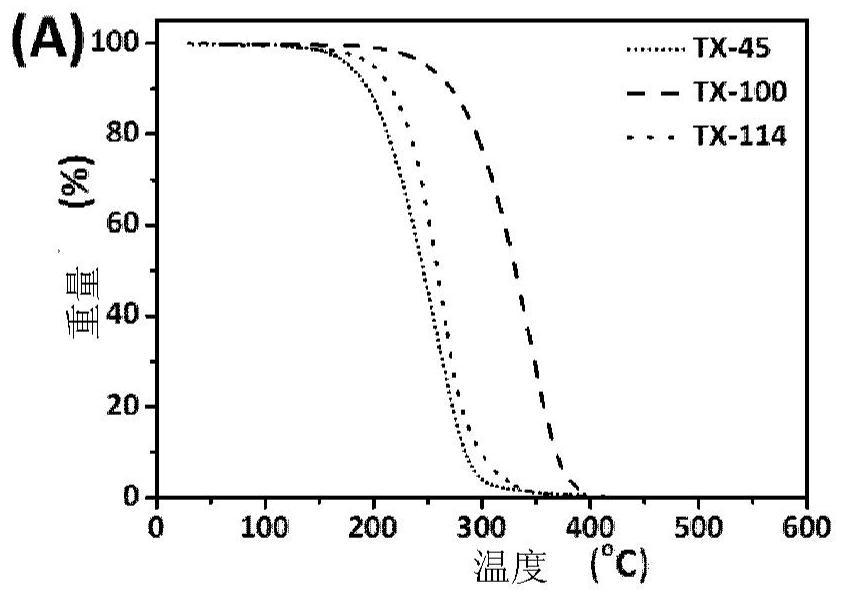

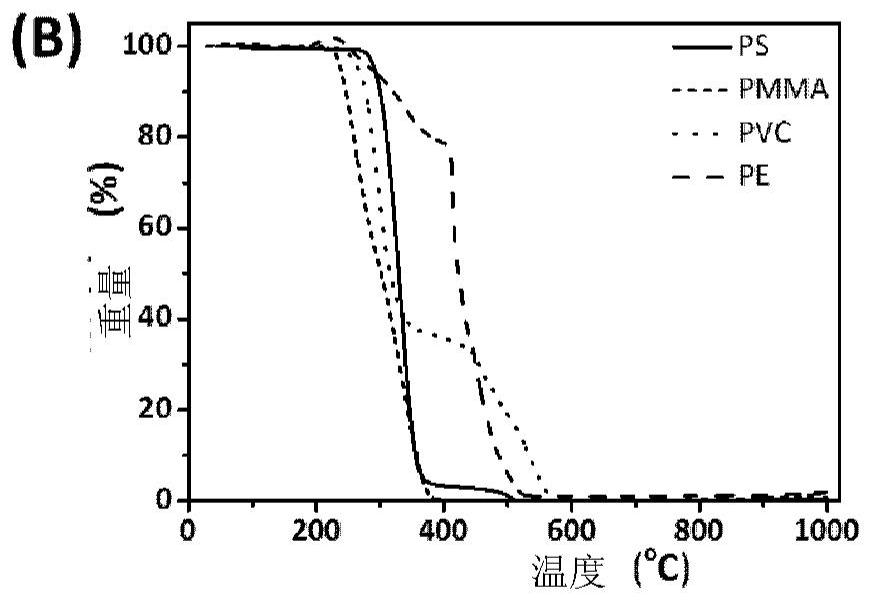

[0030] Such as Figure 2A As shown, the initial thermal decomposition temperatures of surfactants TX-45, TX-100 and TX-114 are about 180 °C, 260 °C and 210 °C, while as Figure 2B As shown, the initial thermal decomposition temperature of polystyrene (PS), polymethyl methacrylate (PMMA), polyvinyl chloride (PVC), polyethylene (PE) nanoplastics is 210 ° C ~ 260 ° C, thus, it can be TX-45 with a lower thermal decomposition temperature was selected as the cloud point extraction agent, and the subsequent heating temperature was determined to be 190°C, and the heating time was 3h, so that TX-45 could be removed before Py-GC / MS detection without affecting the detection of nanoplastics analyze.

[0031] In this embodiment, taking 60nm polystyrene nanoplastics as an example, select MgSO 4 Additional extraction conditions were optimized for ionic strength modifiers. For other extraction conditions such as surfactant concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com