A real-time data storage method

A data storage and real-time technology, applied in the direction of electrical digital data processing, general-purpose stored program computer, digital computer components, etc., can solve the problems of increasing cost, unreachable, affecting the process of micro control unit, etc., and achieve high real-time storage , Improving the effect of real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

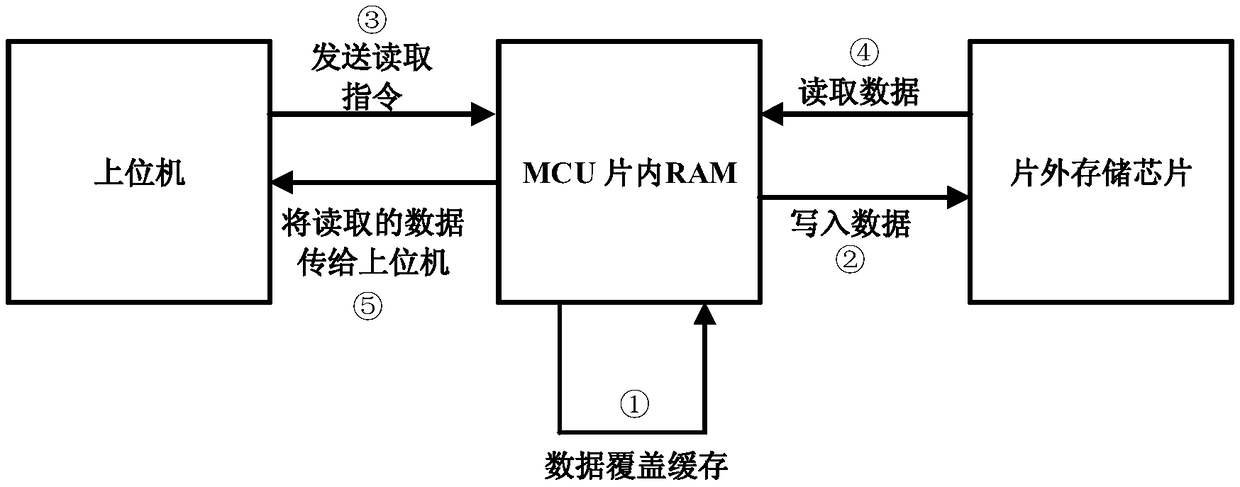

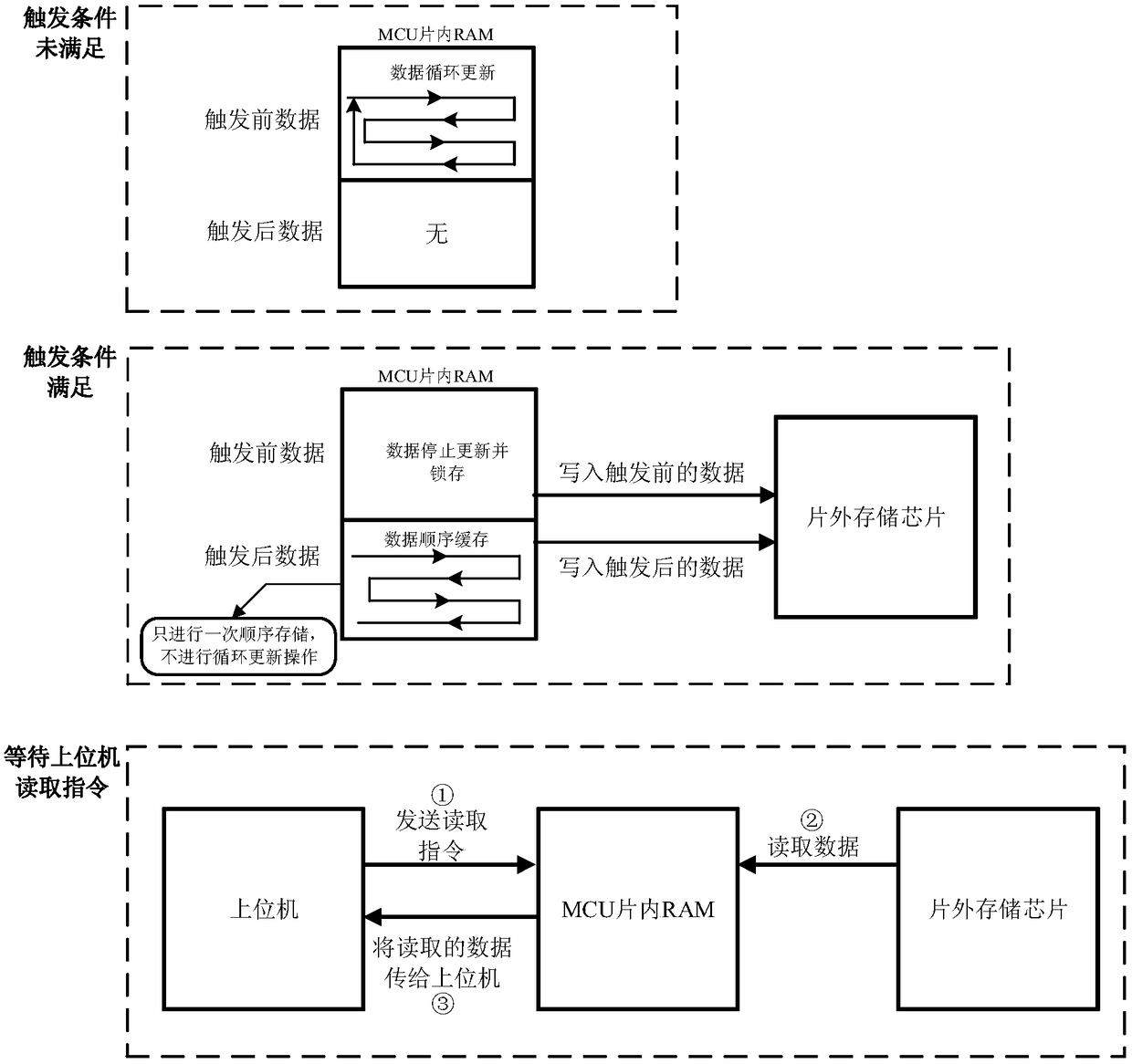

[0031] The real-time data storage method of the invention is applied to a motor drive control system. The storage part of the motor drive control system is composed of three parts: micro control unit, external memory chip and upper computer. Such as figure 1 As shown, data communication is performed between the micro control unit and the external memory chip to complete data storage; data communication is performed between the micro control unit and the host computer to complete data monitoring and display.

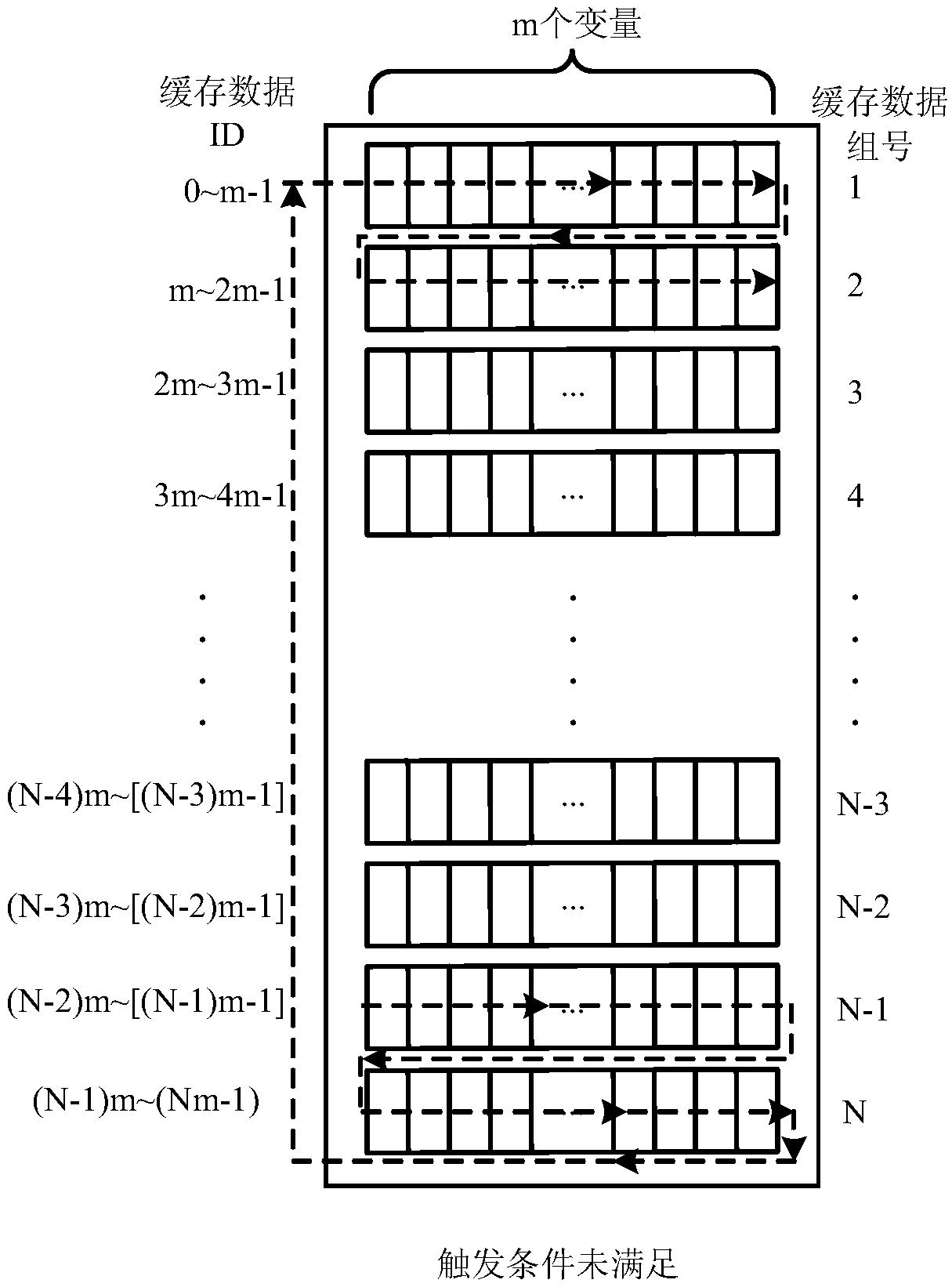

[0032] Such as figure 1 As shown, the real-time data storage method of the present invention caches the variables that need to be cached in the on-chip RAM of the micro-control unit, and caches them in a circular coverage manner; after the data is cached, the micro-control unit writes all cached data to the off-chip memory chip middle; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com