Simulation method of opening radius of energy release hole of high-voltage cable joint explosion-proof device

A technology of explosion-proof devices and high-voltage cables, applied in design optimization/simulation, electrical digital data processing, instruments, etc., can solve problems such as optimization, unfavorable waterproofing, and cumbersome design, and achieve reliable theoretical calculation methods, save test costs, and improve Effect of Preserving Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

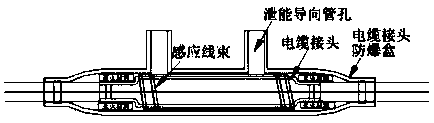

[0044] like Figure 2 to Figure 8 Shown is the embodiment of the simulation method of the opening radius of the energy release hole of the high-voltage cable joint explosion-proof device of the present invention, comprising the following steps:

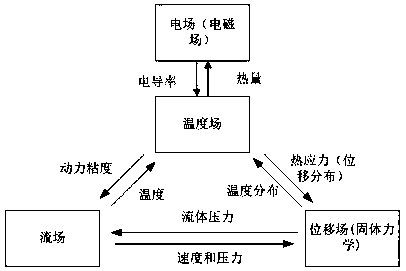

[0045] S1. Using COMSOL Multiphysics multi-physics field coupling simulation software, according to the geometric parameters of each part of the accessories produced by the accessory manufacturer and the electric field strength of the material, the thermal-fluid-solid physical model of the high-voltage cable joint explosion-proof device is established;

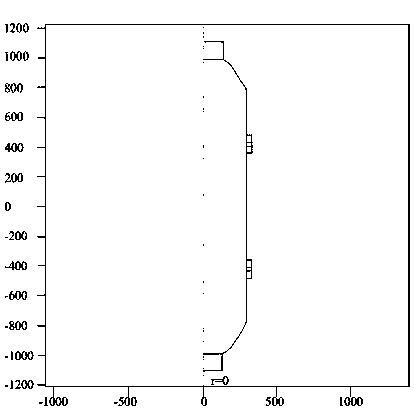

[0046] S2. Coupling the thermal-fluid-solid physical model of the high-voltage cable joint explosion-proof device described in step S1 with multi-physics, and using a multi-layer iterative algorithm to solve it, and calculate the explosion-proof corresponding to the design of energy relief holes of different sizes Maximum air velocity and pressure distribution inside the cavity;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com