A hardware-in-the-loop simulation system of a separation guiding mechanism

A semi-physical simulation and guidance mechanism technology, applied in educational appliances, instruments, teaching models, etc., can solve the problems affecting the development progress and design efficiency, repeated design and testing, and large site area, so as to shorten the development cycle, The effect of improving development efficiency and reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

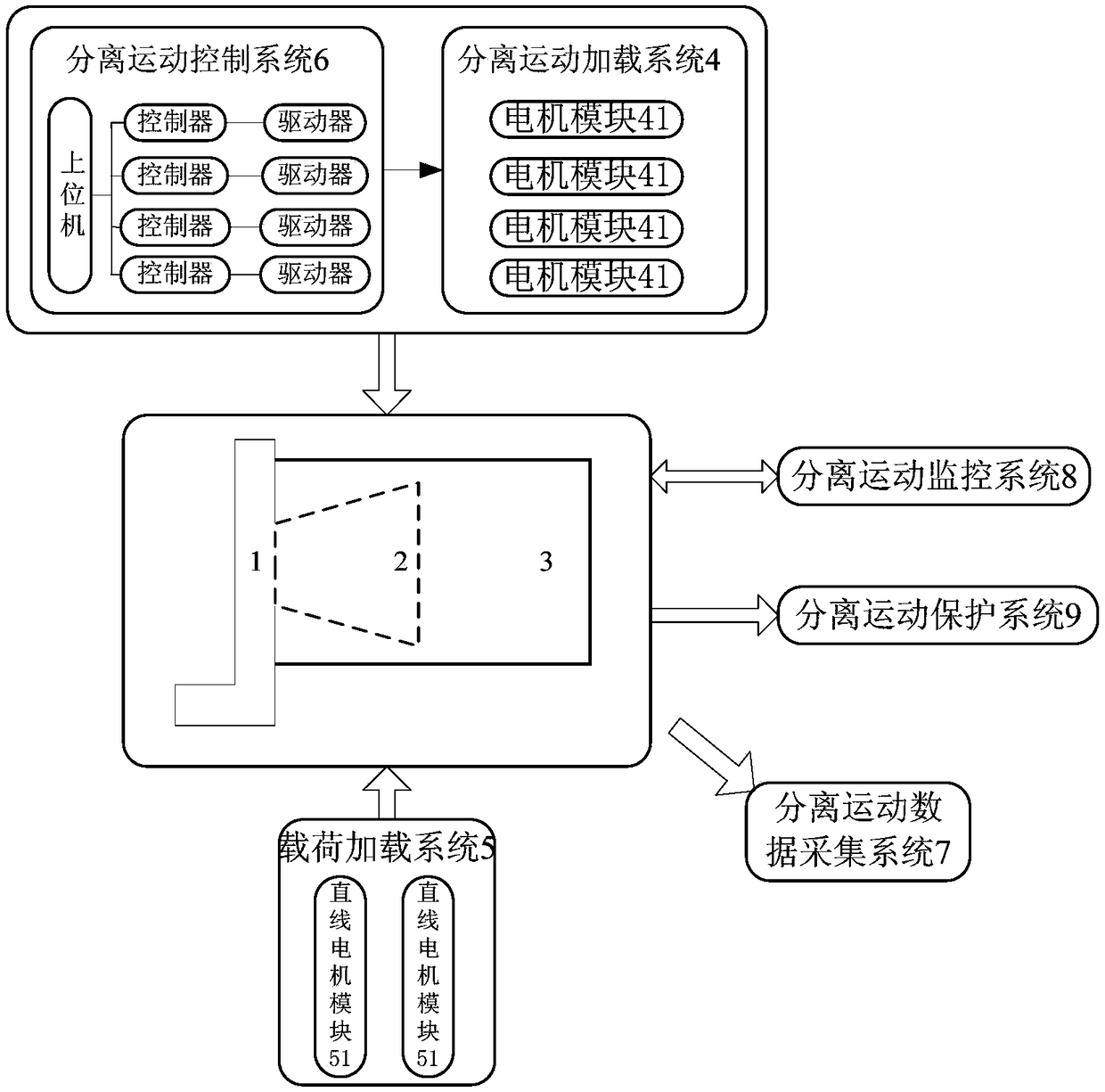

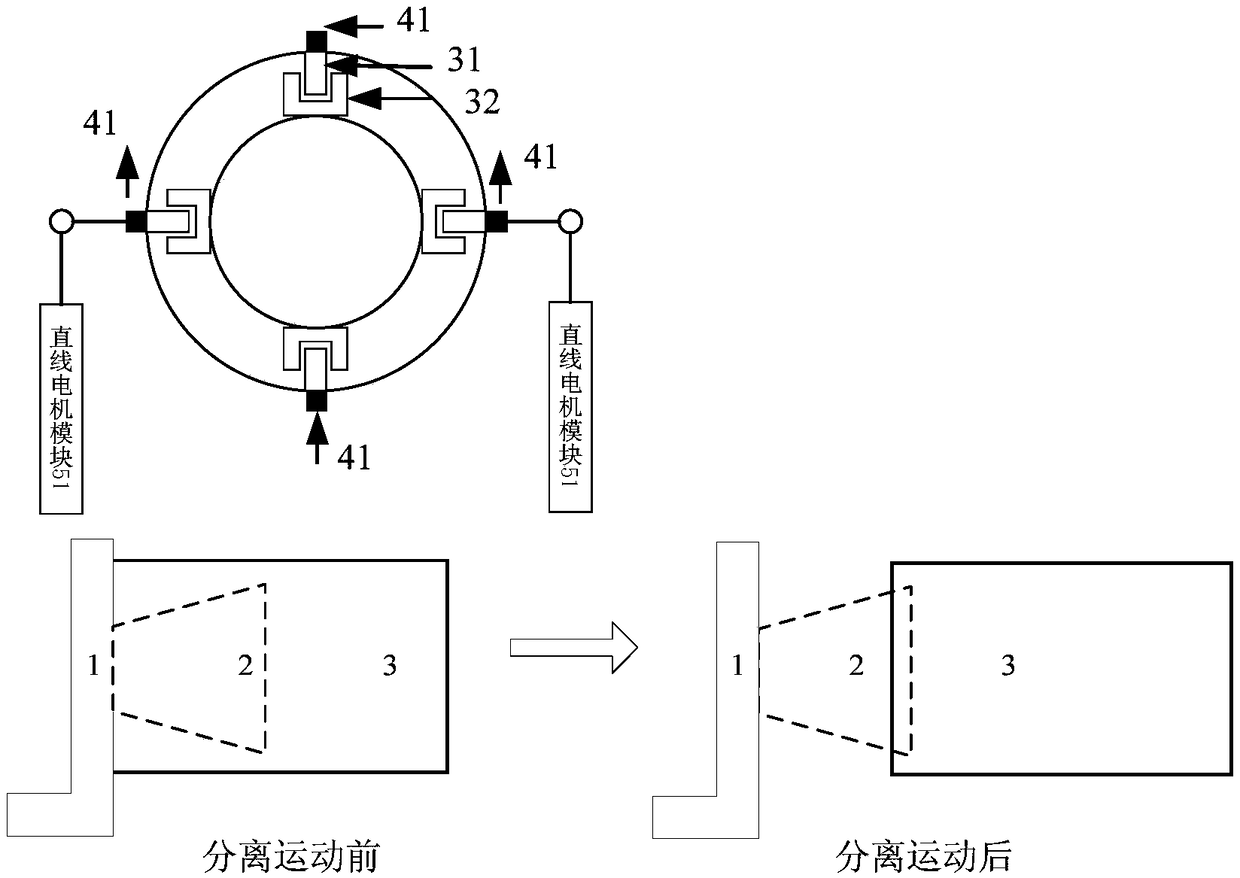

[0034] Such as figure 1 As shown, the present invention proposes a semi-physical simulation system for a separation guide mechanism, including a tooling stand 1, an upper-level engine simulation boundary 2, a lower-level shell segment 3, a separation motion loading system 4, a load loading system 5, a separation Motion control system 6, separate motion data acquisition system 7.

[0035] The upper-level engine simulation boundary 2 is fixed on the tooling platform 1, and the lower-level shell segment 3 is socketed with the upper-level engine simulation boundary 2 through a separation guide mechanism.

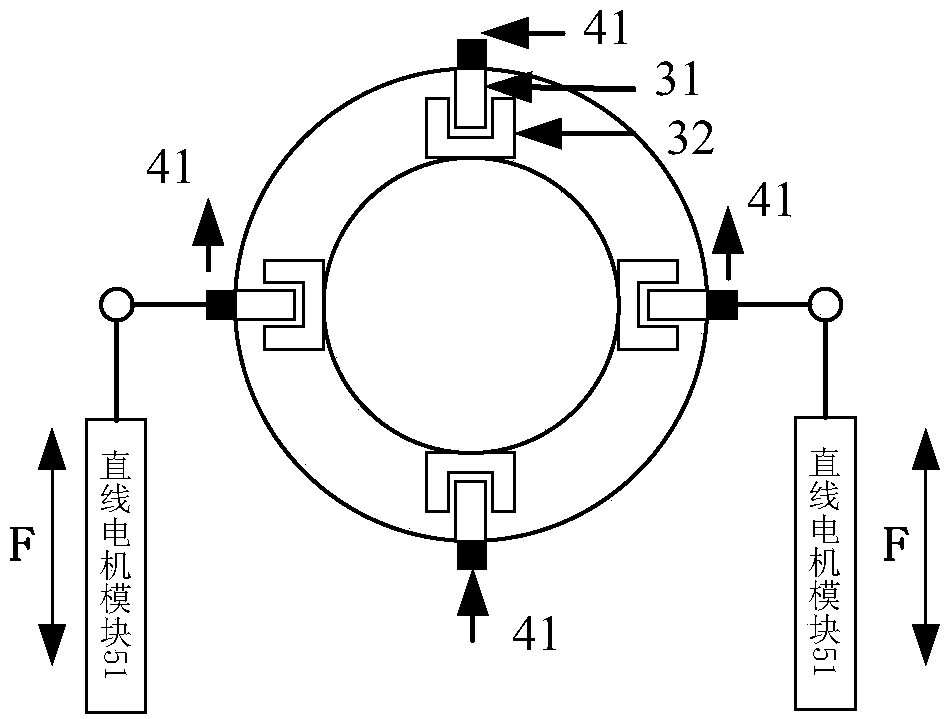

[0036] Specifically, as image 3 As shown, there are four sets of separation guide mechanisms, which are uniformly distributed along the circumferential direction of the shell segment 3 of the next stage. Each group of separation guiding mechanism all comprises long guide rail 31 and guide slider 32, and guide slider 32 is positioned on the outer wall of simulation boundary 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com