Flexible OLED display panel

A display panel, flexible technology, applied in the direction of photovoltaic power generation, electrical components, circuits, etc., can solve the problems of different stress and deformation, affecting the bending and folding of the display panel, and achieve the effects of dispersing stress, increasing the area, and eliminating stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

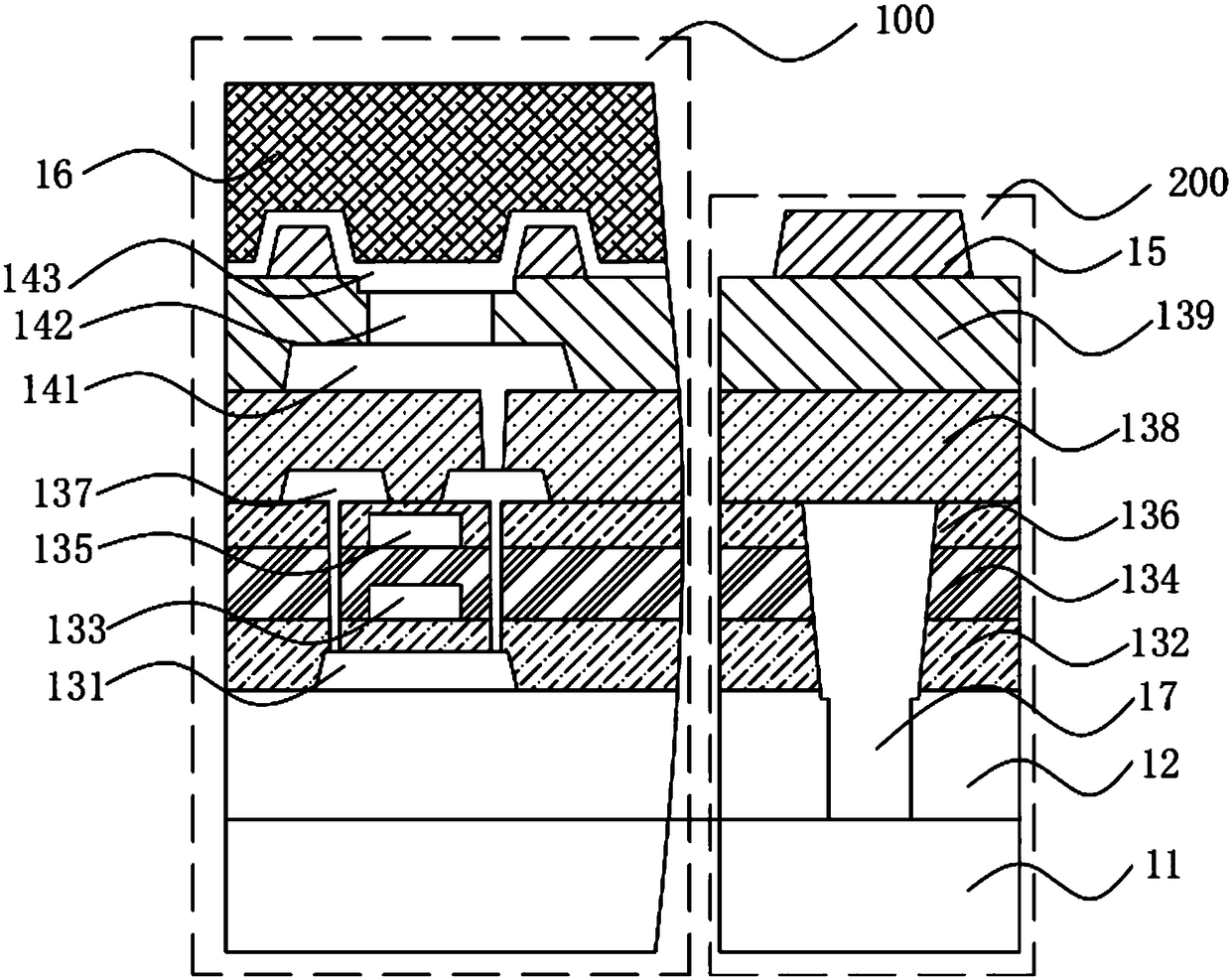

[0027] Such as figure 1 As shown, this embodiment provides a flexible OLED display panel, on which a display area 100 and a bending area 200 are defined, and the flexible OLED display panel includes: a flexible substrate 11; a buffer layer 12, forming On the flexible substrate 11 ; the thin film transistor layer is formed on the buffer layer 12 , the OLED light emitting layer 14 is formed on the thin film transistor layer; the encapsulation layer 16 is formed on the surface of the OLED light emitting layer 14 .

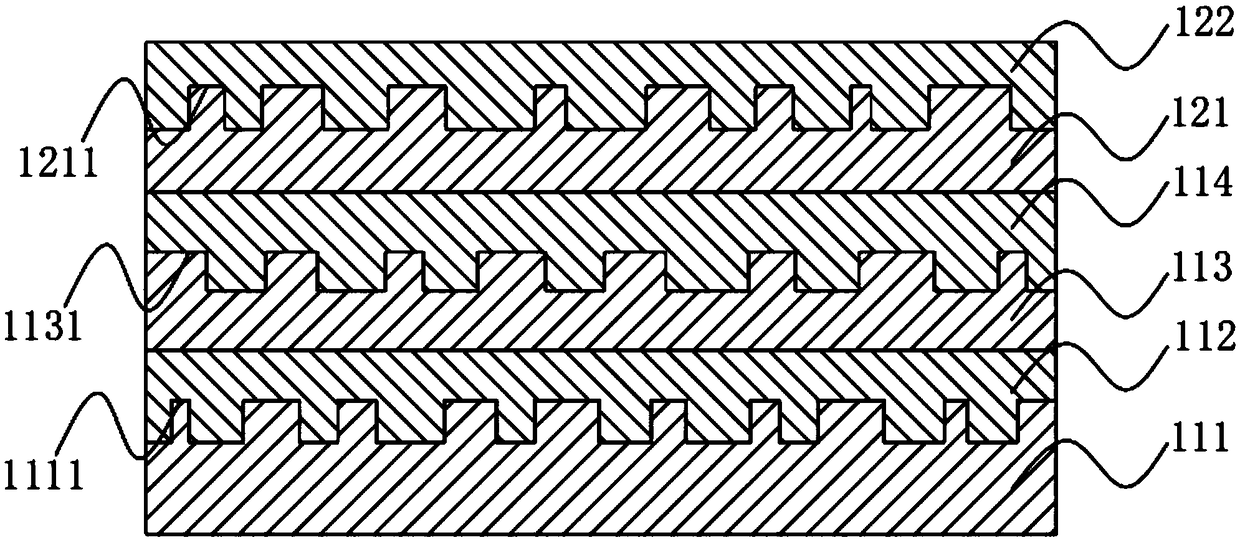

[0028] Such as image 3 As shown, the flexible substrate 11 includes: a first polyimide layer 111; a first barrier layer 112, disposed on the surface of the first polyimide layer 111; a second polyimide layer 113, disposed on the surface of the first barrier layer 112 ; the second barrier layer 114 is disposed on the surface of the second polyimide layer 113 .

[0029] The first polyimide layer 111 is fabricated on a glass substrate (not shown in the figure), and af...

Embodiment 2

[0053] In this embodiment, except that the structure of the thin film transistor layer in the bending region 200 is different from that of the first embodiment, other structures are the same as those described in the first embodiment.

[0054] Such as Figure 4 As shown, in the bending region 200, the second gate insulating layer 134 includes a sixth top surface 1341 with a plurality of protrusions, the sixth top surface 1341 is away from the flexible substrate 11, the layer The lower surface of the inter-insulation layer 136 is in contact with the sixth top surface 1341 to form a concave-convex structure.

[0055] The planarization layer 138 includes a seventh top surface 1381 with a plurality of protrusions, the seventh top surface 1381 faces away from the flexible substrate 11 , the lower surface of the pixel definition layer 139 is in contact with the seventh top surface 1381 contacts to form a concave-convex structure.

[0056] In the bending region 200, by arranging mu...

Embodiment 3

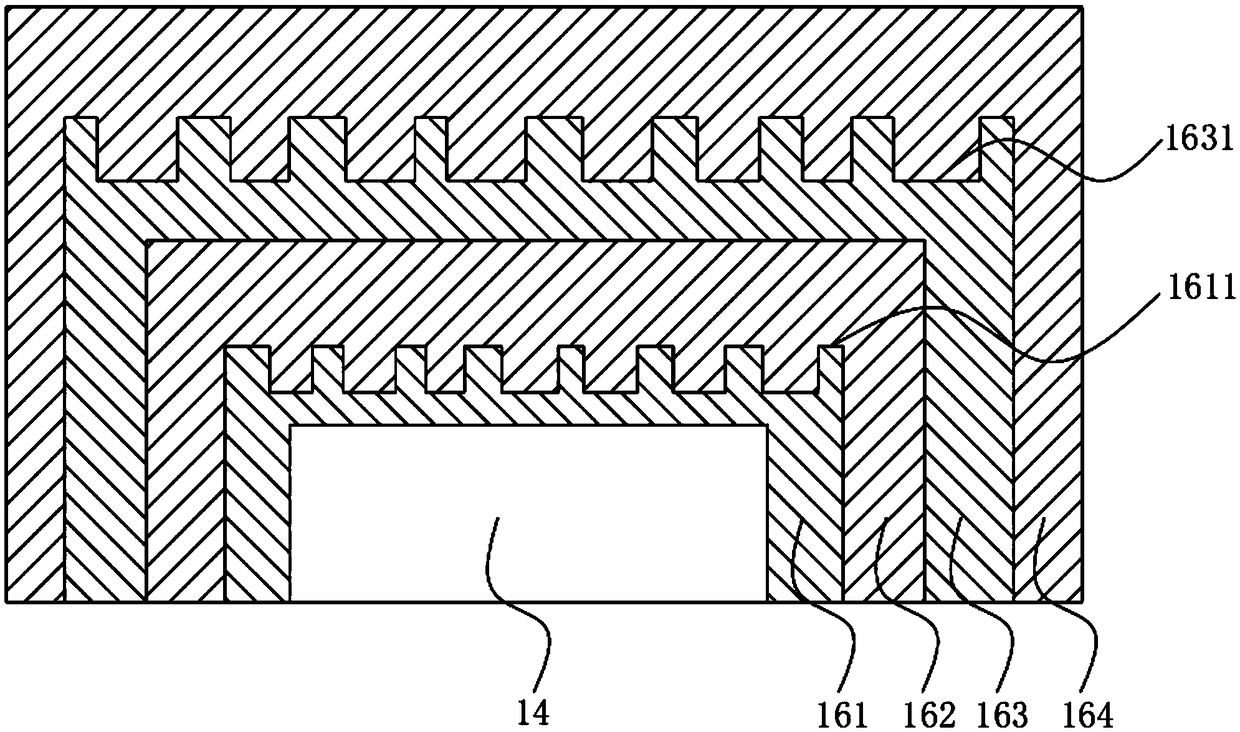

[0059] On the basis of embodiment two, in the film layer deposition process, the mode that adopts Mask (mask plate) to fully expose part film layer is completely removed, as Figure 5 shown.

[0060] In the bending area 200, the second polyimide layer 113 is provided with a plurality of first through holes 1132, and the second barrier layer 114 passes through the first through holes 1132 and the first barrier layer 112. For contact, in the photomask process, a full exposure method is used to form the first through hole 1132 .

[0061] The first buffer layer 121 is provided with a plurality of second through holes 1212 , and the second buffer layer 122 is in contact with the second barrier layer 114 through the second through holes 1212 .

[0062] The first gate insulating layer 132 is provided with a plurality of third through holes 1321 , and the second gate insulating layer 134 is in contact with the second buffer layer 122 through the third through holes 1321 .

[0063] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com