Process for producing vanadium-dioxide-containing particles

A technology of vanadium dioxide, manufacturing method, applied in vanadium oxide, chemical instruments and methods, methods of chemically changing substances by atmospheric pressure, etc. Issues such as mentioning, disclosing, etc., to achieve the effect of high thermochromic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1A

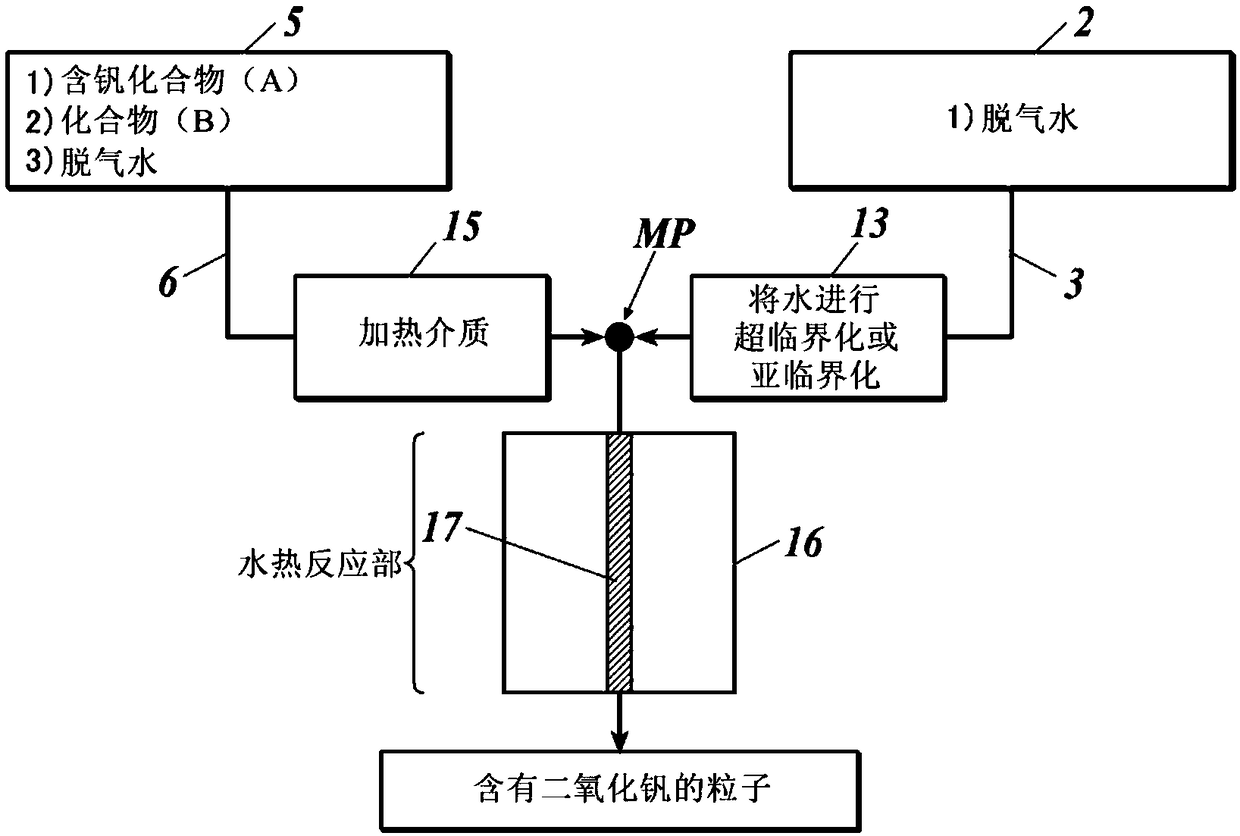

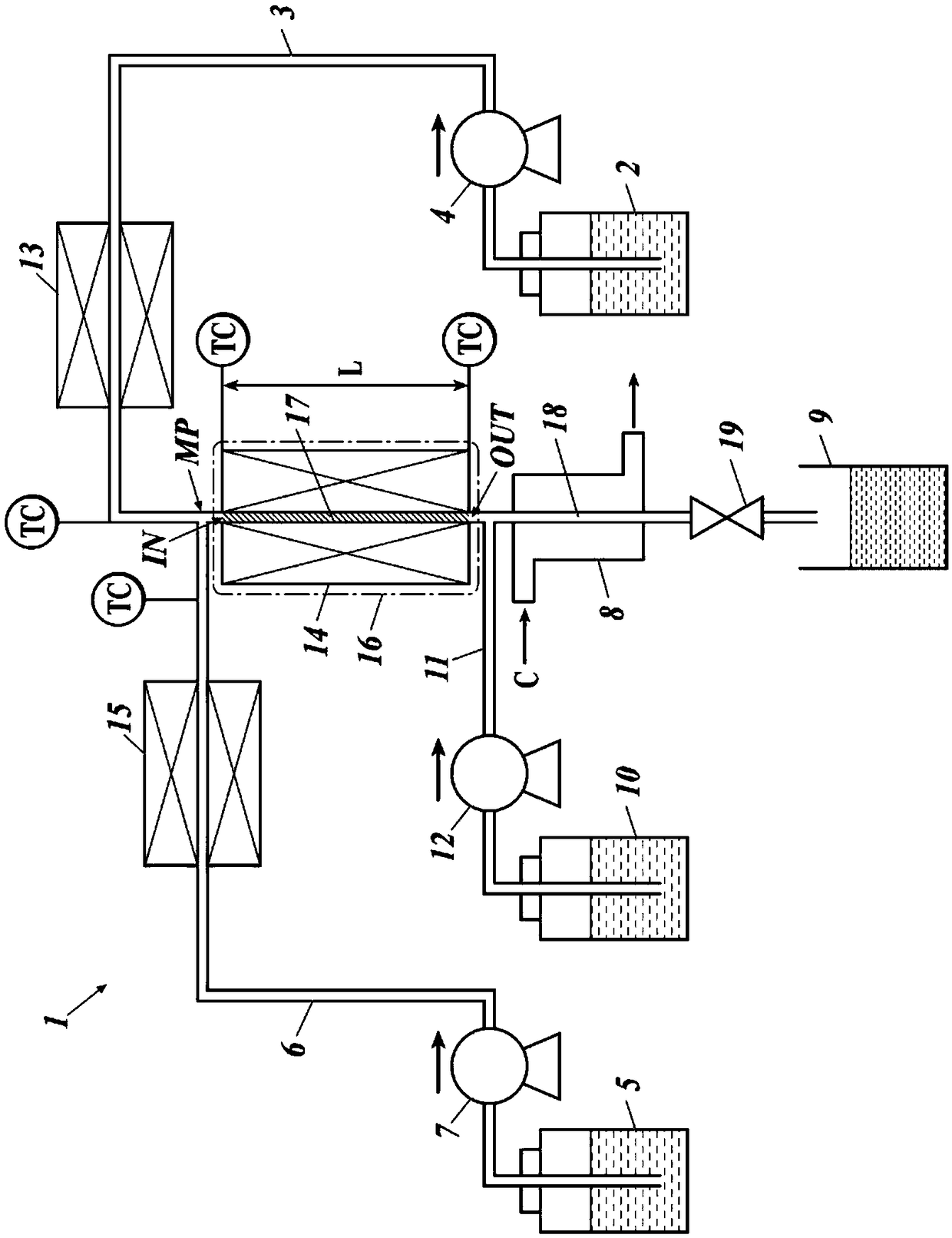

[0122] Embodiment 1A, which is one of the applicable manufacturing processes of manufacturing condition 1, is the following method: Figure 1A As shown, add 1) the raw material liquid containing the vanadium-containing compound (A) and degassed water, 2) the compound (B) that reacts with the vanadium-containing compound to the raw material liquid container one 5, for example, dissolve it in the degassed Alkali or reducing agent for water, add degassed water as water in another raw material liquid container 2, and make the degassed water in a supercritical or subcritical state by using a heating medium 13 at a specified temperature and pressure. After gas and water, the two are combined at the confluence point (MP) to make a reaction solution, and then hydrothermal treatment is performed on the heating part piping 17 in the hydrothermal reaction part 16 constituting the hydrothermal reaction part to prepare particles containing vanadium dioxide. .

Embodiment approach 1B

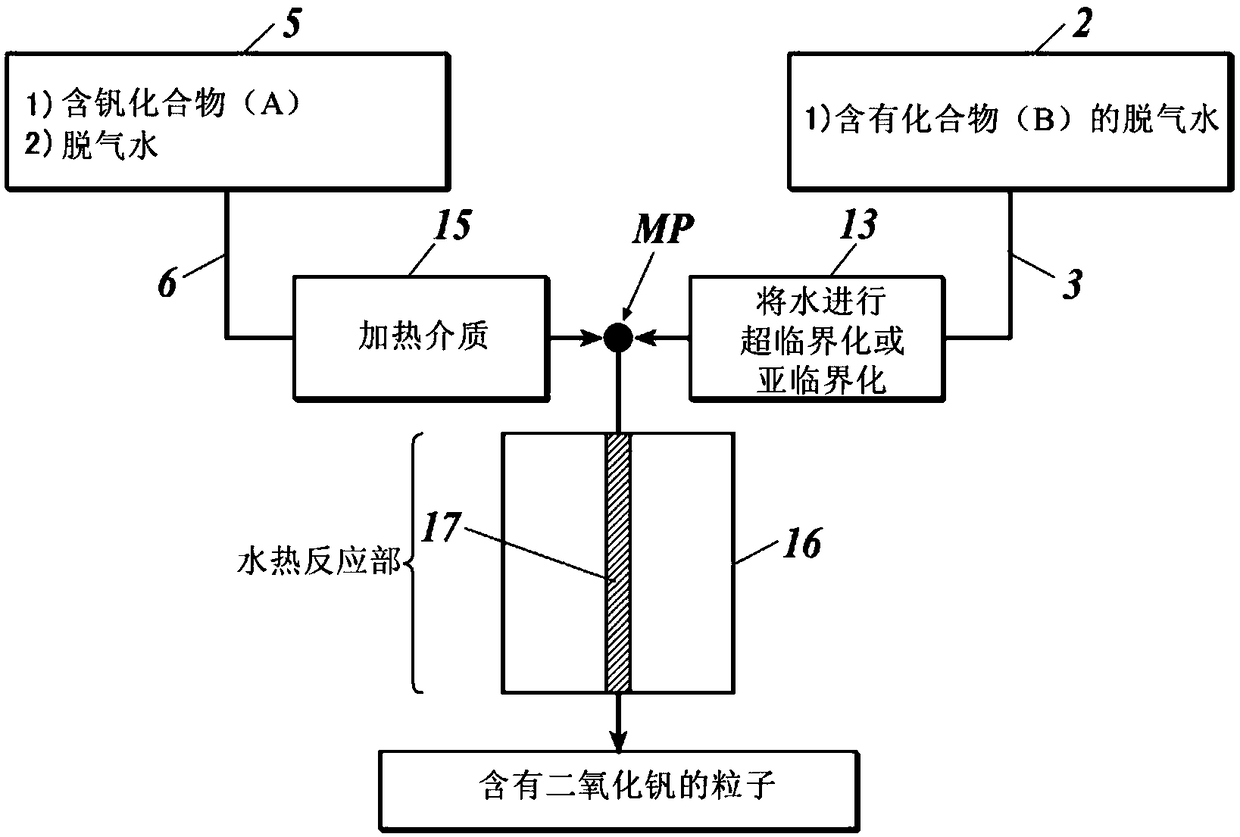

[0124] Embodiment 1B, which is one of the applicable manufacturing processes of manufacturing condition 1, is the following method: Figure 1B As shown, in raw material liquid container one 5, add 1) the raw material liquid that contains vanadium-containing compound (A) and degassed water, in another raw material liquid container two 2, add and contain 2) compound (B) that contains vanadium-containing compound reaction ) degassed water, the degassed water containing the compound (B) that reacts with the vanadium-containing compound is made into degassed water in a supercritical or subcritical state by using a heating medium 13 at a specified temperature and pressure, and then the two After they meet at the confluence point (MP) to form a reaction solution, hydrothermal treatment is performed on the heating section piping 17 in the hydrothermal reaction section 16 constituting the hydrothermal reaction section to prepare vanadium dioxide-containing particles.

[0125] 〔Flow-thr...

Embodiment approach 2

[0253] Embodiment 2 is characterized in that, after preparing a slurry raw material liquid containing at least a vanadium-containing compound and water and a compound reacting with the vanadium-containing compound using a flow-through reaction device having a hydrothermal reaction part, the reaction liquid is The hydrothermal reaction is performed in the hydrothermal reaction section for performing the hydrothermal synthesis constituting the above-mentioned flow-type reaction device with a passage time in the range of 3 to 1000 seconds.

[0254] In the hydrothermal reaction part, the values of the average particle diameter (D) and the polydispersity index (PDI) of the particles containing vanadium dioxide can be made extremely small by carrying out under high pressure and in the presence of supercritical or subcritical water. , particularly excellent thermochromism of the vanadium dioxide-containing particles and transparency of an optical film containing the vanadium dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com