Backpack grease tapping ditching machine

A ditching machine and knapsack-type technology, which is applied in the field of knapsack-type resin mining ditching machines, can solve the problems of inconsistent width of side ditch, affecting the amount of turpentine collection, and difficulty in controlling the depth, so as to improve operating efficiency, simple structure, and ensure collection. volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

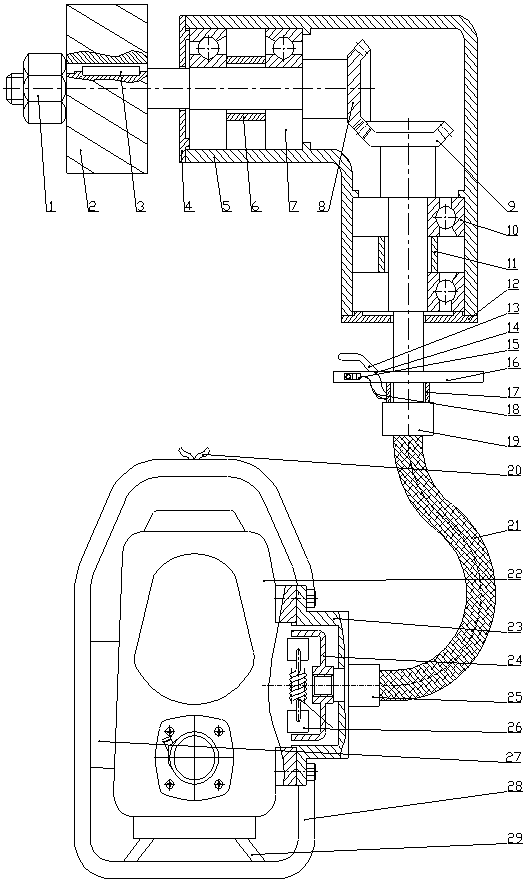

[0011] exist figure 1 Among them, after starting the small gasoline engine (22), the gasoline engine (22), the end cover (23) etc. are carried on the back of the person by carrying the belt (20), the carrying frame (28). Hold the handle (16) tightly with your hands, flatten the ditch cutter (2), and approach the trunk, increase the throttle switch (13) to make the output speed of the gasoline engine (22) reach a predetermined value, and now the elastic clutch (26) opens In close contact with the connection cover (24), the flexible shaft (21) is driven to rotate through the power source joint (25), and the output speed of the flexible shaft (21) is transmitted to the bevel gear shaft B (9) via the working end joint (19) , Bevel gear shaft B (9) relies on gear meshing to transmit motion to bevel gear shaft A (8), and bevel gear shaft A (8) drives the ditching knife (2) fixedly connected with it to rotate at high speed, waiting for ditching operations.

[0012] Hold the handle (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com