Method for recycling and reusing ionic exchange regenerated liquid

A technology of ion exchange and ion exchange column, which is applied in the field of ion exchange regenerated liquid recovery and utilization, can solve the problems of difficult treatment, high ammonia nitrogen content, and high cost, and achieve the effects of reducing waste water discharge, large economic benefits, and saving washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

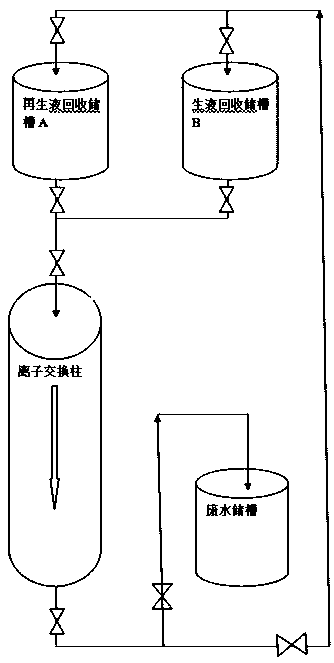

[0024] A kind of ion exchange regenerated liquid recycling method described in conjunction with accompanying drawing comprises the following steps:

[0025] 1) When the ion exchange column is regenerated, operate as a single column. After analysis, wash the ion exchange column with tap water for half an hour, with a flow rate of 4m³ / h; The washing water can flow out smoothly, and stop backwashing after 45 minutes. The total time is 1 hour and 15 minutes, and the shared water is 5 m³;

[0026] 2) After washing with water, the water in the ion exchange column is full, and the liquid level in the ion exchange column is lowered to 15-20cm above the resin layer;

[0027] 3) Open th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com