A linear friction welding method

A linear friction welding, friction plate technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems that the zero return accuracy cannot meet the technical requirements of the product, the valve port is large, and the cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

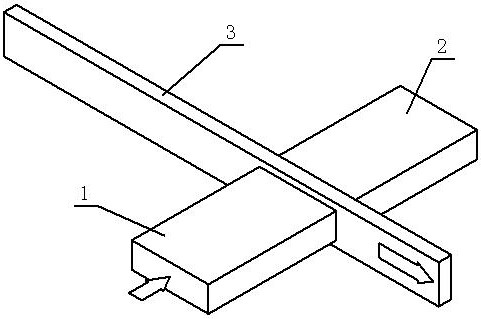

[0034] figure 1 A schematic structural view of an embodiment of a linear friction welding method of the present invention is shown. The first weldment 1 and the second weldment 2 and the friction plate 3 are carried out according to the method. Since there is no equipment to test this method, only ANSYS software can be used for numerical simulation. The model material is set to TC4, and the friction upsetting force is 10000kg , the moving speed of the friction piece is set to 500mm / s.

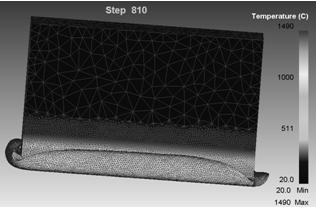

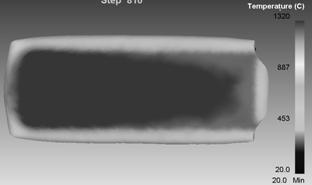

[0035] Such as figure 2 As shown, the flash is extruded on the contact surface of the first weldment 1 and the second weldment 2, and the flash in the unidirectional friction welding process is similar to the linear friction welding, the difference is that at the front end of the friction plate 3 in the forward direction, the flash The edge is small, while the rear end of the friction plate 3 in the advancing direction is larger and curled. There is no ripple mark on the flash edges of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com