Rubber sheet for solar industry and preparation process thereof

A preparation process and technology for rubber sheets, applied in the rubber field, can solve the problems of surface corrosion resistance, poor oxidation resistance, cracking of anti-corrosion coatings on hard ductile surfaces, and low production efficiency, and achieve ductility, guaranteed performance, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

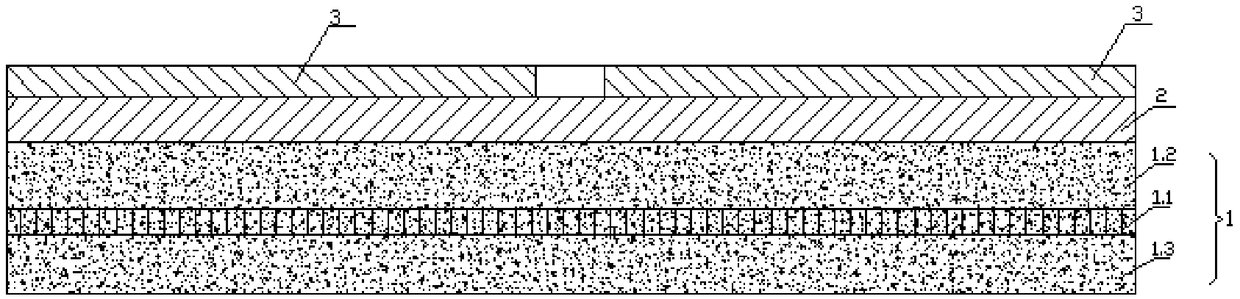

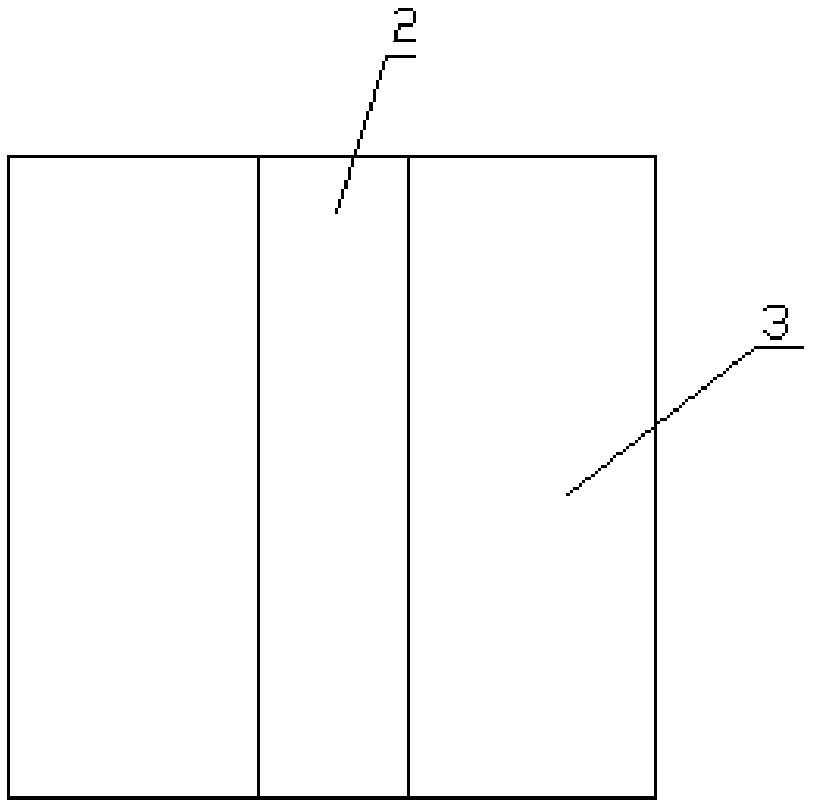

[0015] see figure 1 and figure 2 , the invention relates to a rubber sheet for solar energy industry, the rubber sheet includes a rubber body 1, the rubber body 1 includes a skeleton cloth 1.1 in the middle, and composites on the upper surface and the lower surface of the skeleton cloth 1.1 respectively The upper rubber layer 1.2 and the lower rubber layer 1.3; the upper surface of the upper rubber layer 1.2 is provided with two PTFE films 3 along the length direction of the rubber body 1, and the two PTFE films 3 are parallel to each other and do not touch;

[0016] A preparation process of rubber sheets for solar energy industry, the process steps are: two PTFE membranes 3 and rubber body 1 are integrally formed through a drum vulcanizer;

[0017] Further, the upper rubber layer 1.2 and the lower rubber layer 1.3 are made of silica gel;

[0018] In addition: it should be noted that the above specific implementation is only an optimization solution of this patent, and any ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com