Cellulose/animal hair composite material for friction nano generator and self-driving sensor and preparation method thereof

A nano-generator and animal hair technology, applied in the field of nano-new energy, can solve the problems of high cost and low output power of the friction nano-generator, and achieve the effects of low cost, light weight and less materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

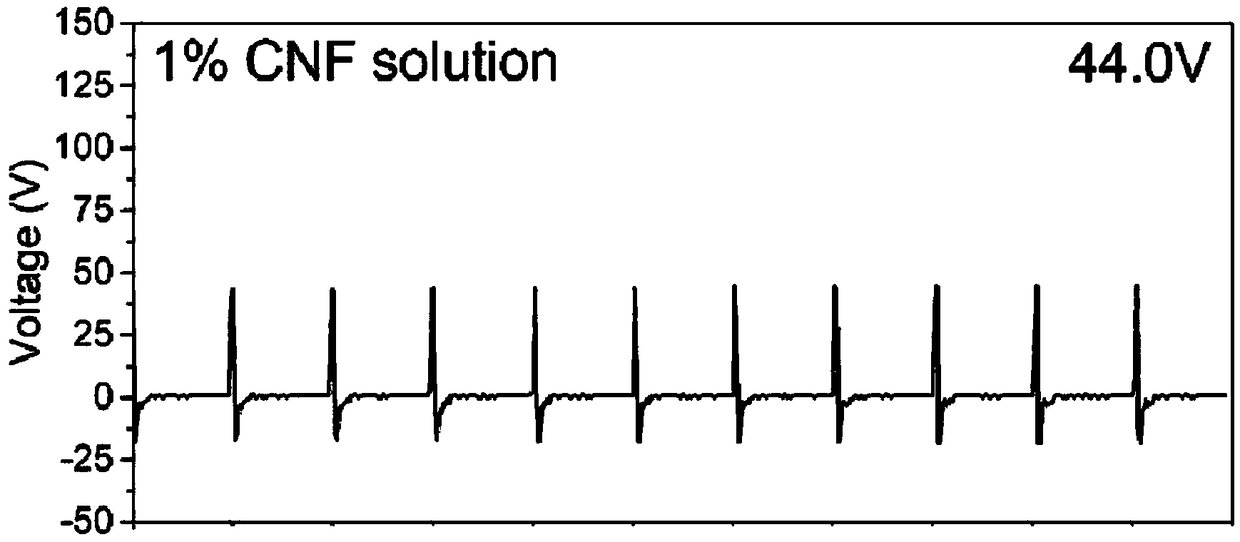

[0042] The present embodiment provides a preparation method of a triboelectric nanogenerator and a cellulose / animal hair composite material for a self-driven sensor, which specifically includes the following steps:

[0043] S1. Weigh 0.05g of cellulose and disperse it in 5mL of water to prepare a 1% cellulose solution;

[0044] S2. Wash the hair with water and ethanol, and dry it in a vacuum drying oven for 1 hour;

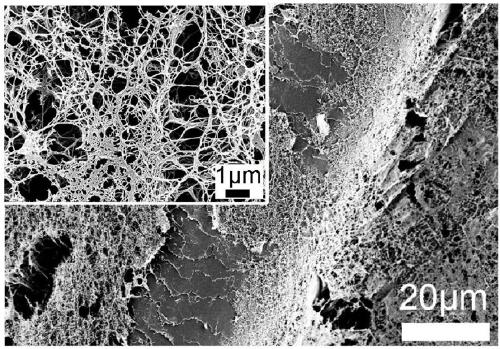

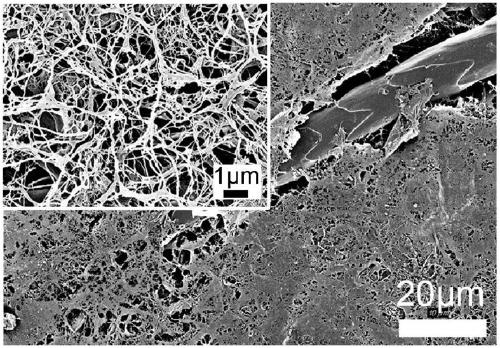

[0045] S3. Add hair of the same quality as cellulose to the solution in step S1, stir to fully disperse the hair in the solution, pre-freeze the mixed solution at -80°C for 1 hour, and cool the pre-frozen mixed solution at -80°C C, the pressure is freeze-drying under the condition of 0.4mBar for 3 days to obtain cellulose / hair aerogel;

[0046] S4. Compress the aerogel prepared in step S3 into a thin film with a thickness of 0.2 mm, that is, to obtain a cellulose / hair composite material for triboelectric nanogenerators and self-driven sensors.

Embodiment 2

[0048] The preparation method of the composite material of this embodiment refers to Example 1, except that the animal hair used is rabbit hair, the quality of rabbit hair is the same as that of cellulose, and the prepared composite material is a cellulose / rabbit hair composite material.

Embodiment 3

[0050] The present embodiment provides a preparation method of a triboelectric nanogenerator and a cellulose / animal hair composite material for a self-driven sensor, which specifically includes the following steps:

[0051] The composite porous material was prepared by using hair and cellulose.

[0052]S1. Weigh 0.15g of cellulose and disperse it in 5mL of water to prepare a 3% cellulose solution;

[0053] S2. Wash the hair with water and ethanol, and dry it in a vacuum drying oven for 1 hour;

[0054] S3. Add 50% of the cellulose mass of hair to the cellulose solution in S1, stir to fully disperse the hair in the solution, pre-freeze the mixed solution at –80°C for 1 hour, and freeze the pre-frozen mixed solution at temperature Freeze-dried for 3 days at –80°C and pressure of 0.4mBar to obtain aerogel;

[0055] S4. Compress the aerogel prepared in step S3 into a thin film with a thickness of 0.2 mm, that is, to obtain a cellulose / hair composite material for triboelectric na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com