Polybutyl acrylate-poly-n-butyl methacrylate copolymer for nano generators and self-driven sensors and preparation method thereof

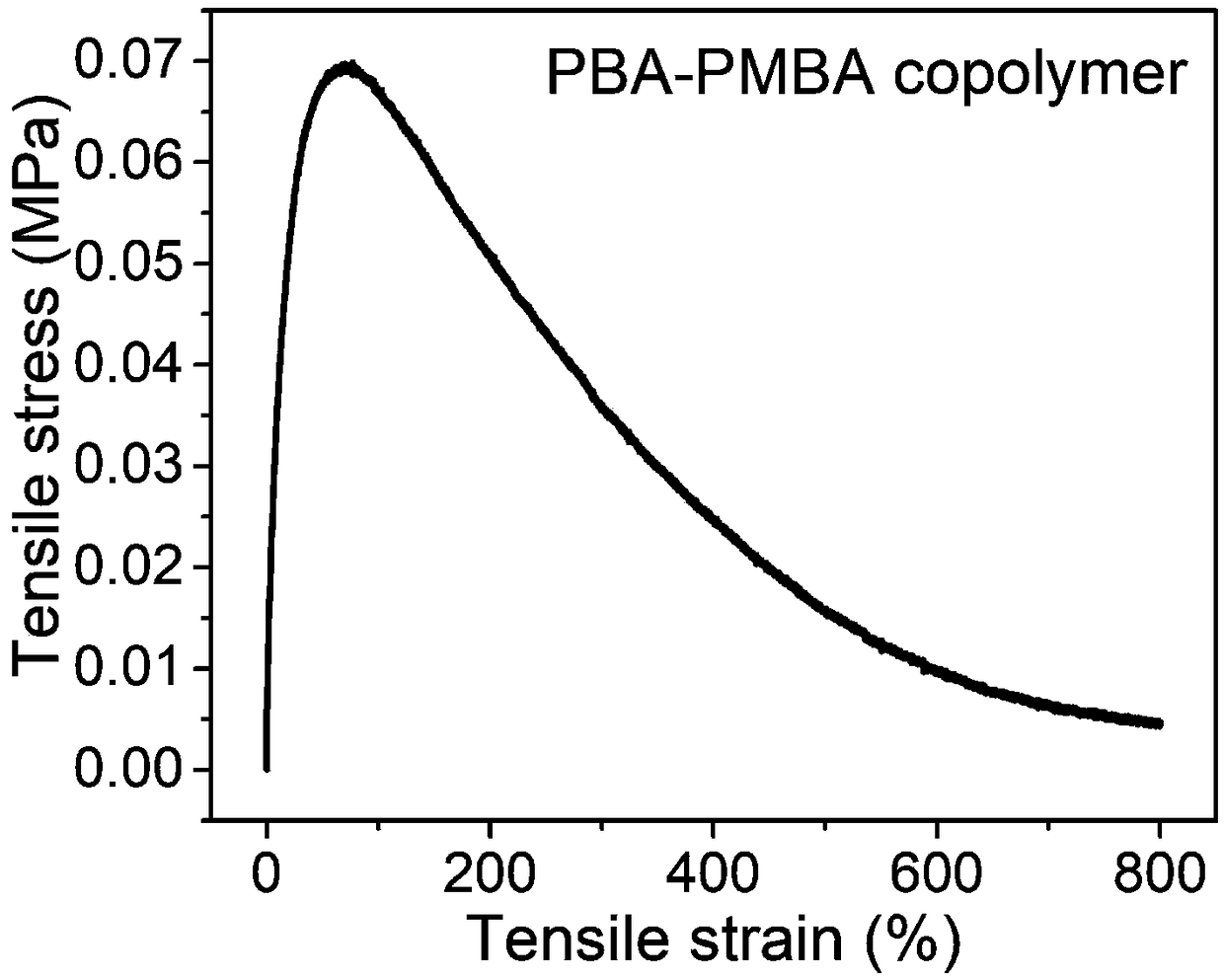

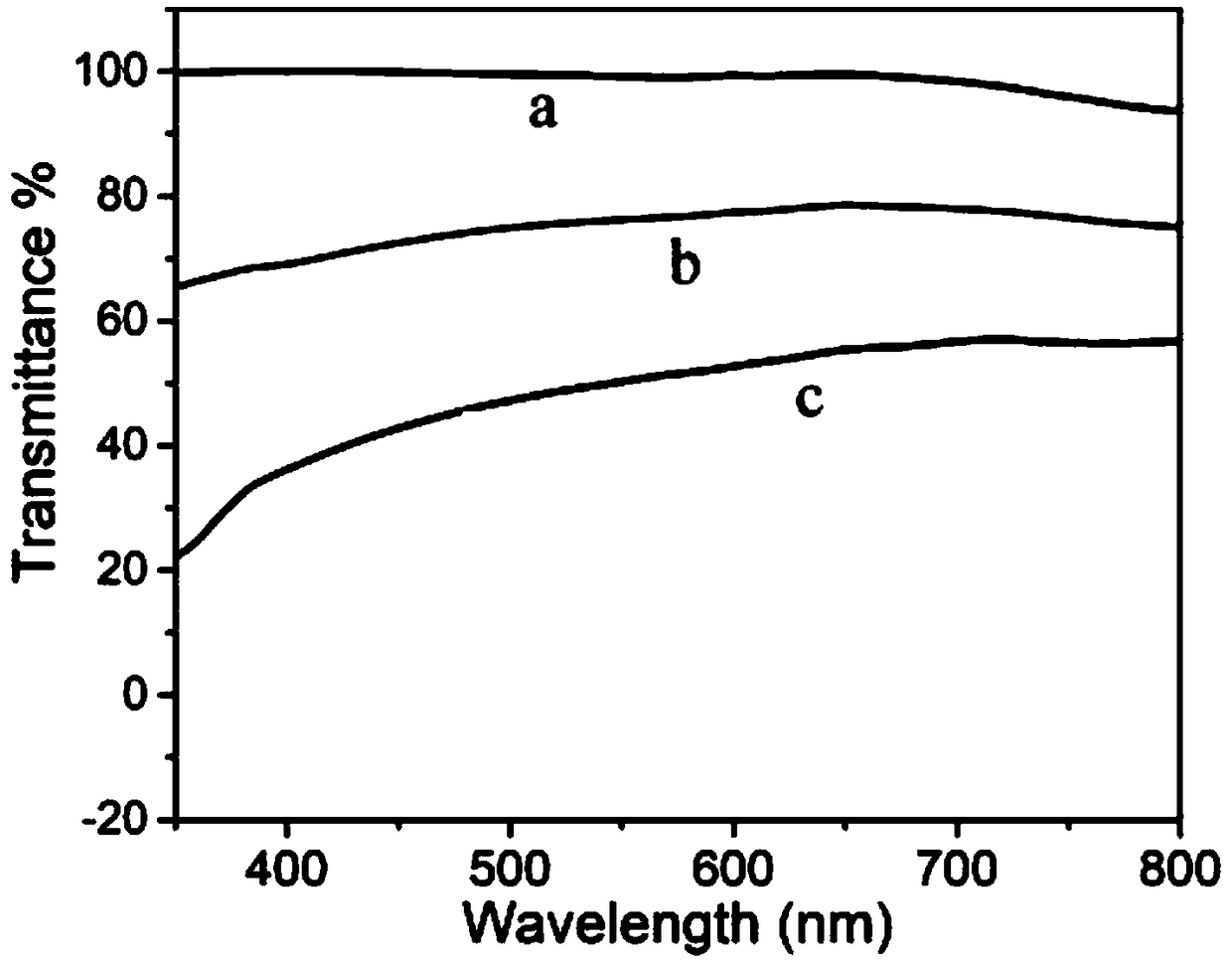

A technology of polybutyl methacrylate and polybutyl acrylate, which is applied in the measurement of the property and force of piezoelectric devices, electromagnetic measurement devices, and electric/magnetic solid deformation measurement, etc., which can solve the problem of lack of transparency and limited applications , lack of flexibility and other issues, to achieve the effect of good flexibility and transparency, high power, and strong ability to lose electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a preparation method of polybutyl acrylate-polybutyl methacrylate copolymer for flexible nanogenerators and self-driving sensors. The specific steps are:

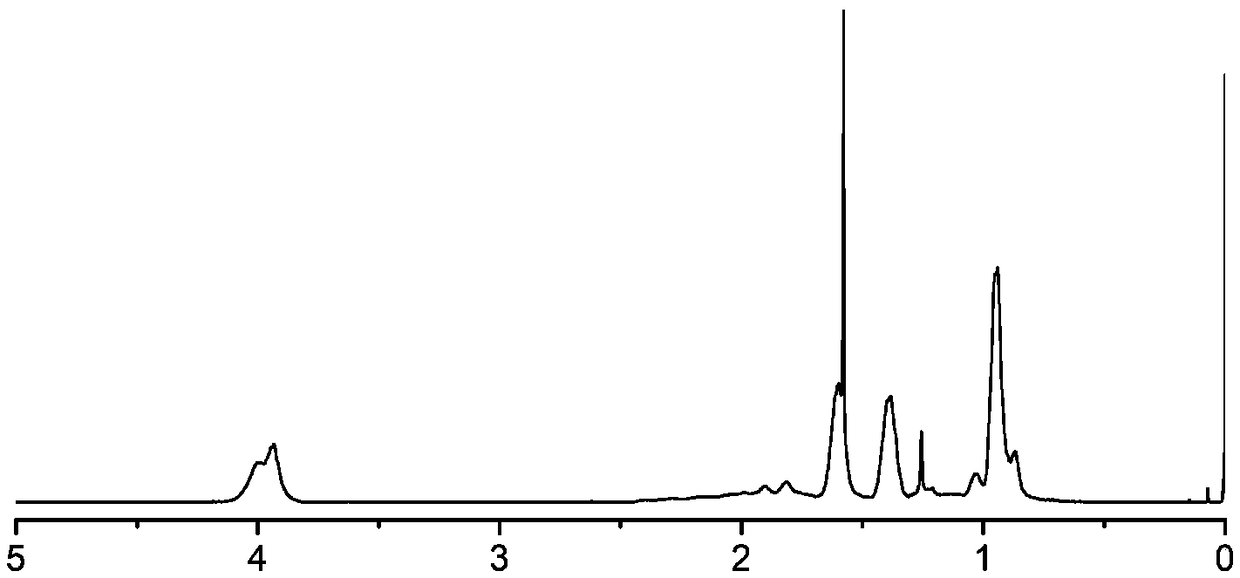

[0035] S1. Add 30mmol butyl acrylate, 90mmol butyl methacrylate, 0.4mmol 4-methylbenzophenone, 0.4mmol cuprous bromide and 0.4mmol pentamethyldivinyltriamine to the two-necked flask successively, The reactants in the reaction were refrigerated and vacuum deaerated and then sealed in a vacuum environment. Then react 15h in oil bath at 90 DEG C, obtain polybutyl acrylate-polybutyl methacrylate copolymer;

[0036] S2. the obtained polybutyl acrylate-polybutyl methacrylate copolymer is dissolved in chloroform, and then extracted and purified in methanol / 5% hydrochloric acid solution to obtain polybutyl acrylate-polybutyl methacrylate copolymer. The purified product is dried;

[0037] S3. The polybutyl acrylate-polybutyl methacrylate copolymer dried in step S2 is hot-pressed at 100 ° C to form a...

Embodiment 2

[0039] This embodiment provides a preparation method of polybutyl acrylate-polybutyl methacrylate copolymer for flexible nanogenerators and self-driving sensors. The specific steps are:

[0040] S1. Add 30mmol butyl acrylate, 60mmol butyl methacrylate, 0.4mmol 4-methylbenzophenone, 0.4mmol cuprous bromide and 0.8mmol 4,4'-dinonyl-2,2'- Bipyridyl was added into a two-necked flask, and the reactants in the flask were refrigerated and vacuum-deaerated and then sealed in a vacuum environment. Then at 70 DEG C of oil bath 10h, obtain polybutyl acrylate-polybutyl methacrylate copolymer;

[0041] S2. the obtained polybutyl acrylate-polybutyl methacrylate copolymer is dissolved in chloroform, and then extracted and purified in methanol / 5% hydrochloric acid solution to obtain polybutyl acrylate-polybutyl methacrylate copolymer. The purified product is dried;

[0042] S3. The polybutyl acrylate-polybutyl methacrylate copolymer dried in step S2 is hot-pressed to form a film at 80° C. t...

Embodiment 3

[0044] This embodiment provides a preparation method of polybutyl acrylate-polybutyl methacrylate copolymer for flexible nanogenerators and self-driving sensors. The specific steps are:

[0045] S1. Add 30mmol butyl acrylate, 120mmol butyl methacrylate, 0.4mmol 4-methylbenzophenone, 0.4mmol cuprous bromide and 0.8mmol 4,4'-dinonyl-2,2'- Bipyridyl was added into a two-necked flask, and the reactants in the flask were refrigerated and vacuum-deaerated and then sealed in a vacuum environment. Then at 90 DEG C of oil bath 20h, obtain polybutyl acrylate-polybutyl methacrylate copolymer;

[0046] S2. the obtained polybutyl acrylate-polybutyl methacrylate copolymer is dissolved in chloroform, and then extracted and purified in methanol / 5% hydrochloric acid solution to obtain polybutyl acrylate-polybutyl methacrylate copolymer. The purified product is dried;

[0047]S3. The polybutyl acrylate-polybutyl methacrylate copolymer dried in step S2 is hot-pressed to form a film at 120° C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com